20

MAINTENANCE

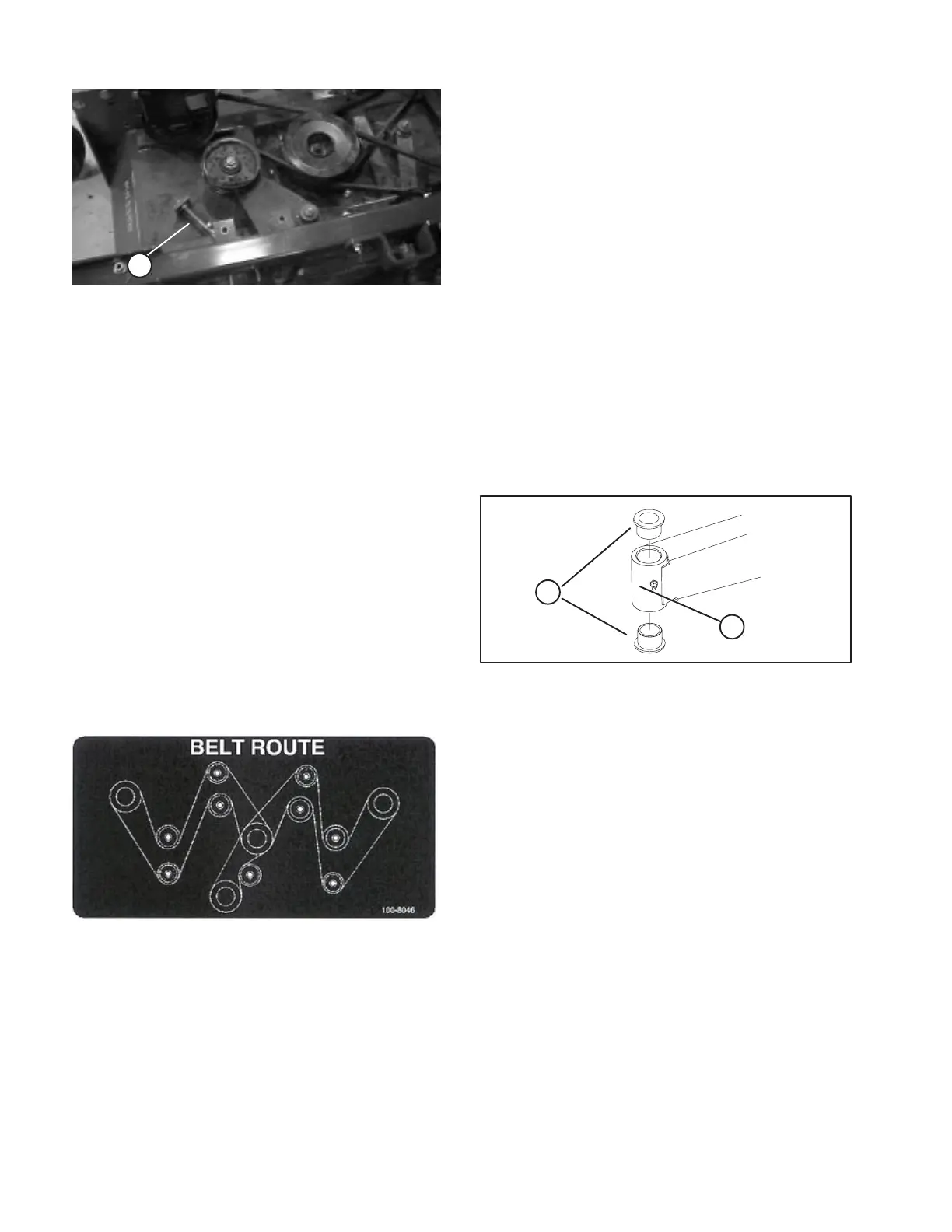

Figure 31

1. Spring tensioning rod (3)

1

REPLACING DRIVE BELTS

The blade drive belts, tensioned by the spring loaded

idlers, are very durable. However, after many hours of

use, the belts will show signs of wear. Signs of a worn

belt are: squealing when belt is rotating, blades

slipping when cutting grass, frayed edges, burn marks

and cracks. Replace the belt if any of these conditions

are evident.

1. Lower cutting unit to the shop floor. Remove belt

covers from top of cutting unit and set covers aside.

2. To replace gear box belt, loosen spring tension rod

and remove belt. Retention new belt to 30 lbs. Refer to

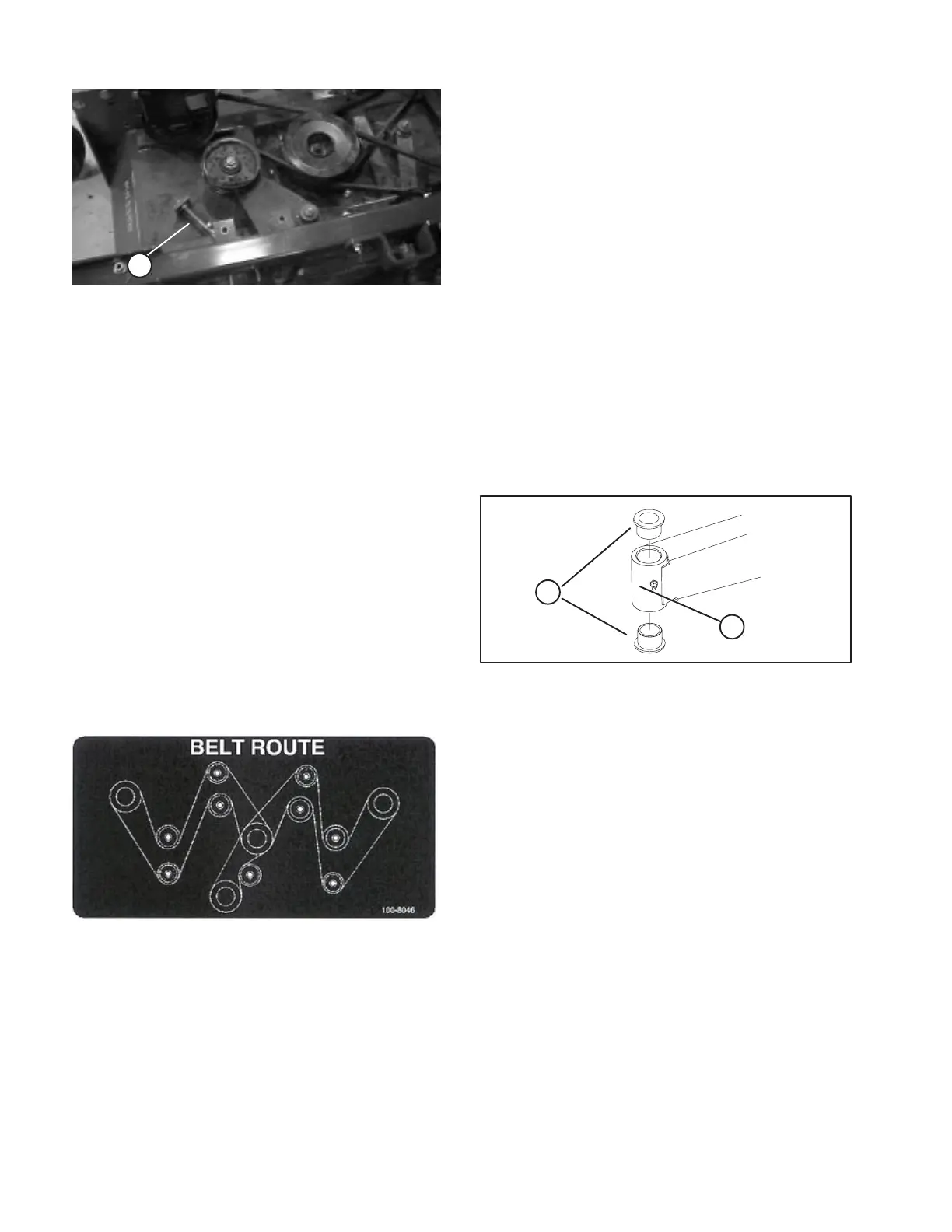

Figure 32 for belt routing.

Figure 32

3. To replace wing belts, loosen spring tension rod

and remove gear box belt.

4. Pull spring loaded idler pulley away from belt, with

hand, to relieve belt tension and remove belt. Retention

new belts to 10 lbs. Refer to Figure 32 for belt routing.

8. Reinstall belt covers.

SERVICING FRONT BUSHINGS IN

CASTOR ARMS

The castor arms have bushings pressed into the top

and bottom of the tube and after many hours of

operation, the bushings will wear. To check the

bushings, move castor fork back and forth and from

side to side. If castor spindle is loose inside the

bushings, bushings are worn and must be replaced.

1. Raise cutting unit so wheels are off floor and block

it so it cannot fall accidentally.

2. Remove tensioning cap, spacer(s) and thrust

washer from top of castor spindle.

3. Pull castor spindle out of mounting tube. Allow

thrust washer and spacer(s) to remain on bottom of

spindle.

4. Insert pin punch into top or bottom of mounting

tube and drive bushing out of tube. Also drive other

bushing out of tube. Clean inside of tubes to remove

dirt.

Figure 33

1. Front Castor Arm Tube

2. Bushings

1

2

5. Apply grease to inside and outside of new

bushings. Using a hammer and flat plate, drive

bushings into mounting tube.

6. Inspect castor spindle for wear and replace it if

damaged.

7. Push castor spindle through bushings and

mounting tube. Slide thrust washer and spacer(s) onto

spindle. Install tensioning cap on castor spindle to

retain all parts in place.

SERVICING CASTOR WHEELS AND

BEARINGS

The castor wheel rotates on a high-quality roller

bearing and is supported by a spanner bushing. Even

after many hours of use, provided that the bearing was

kept well-lubricated, bearing wear will be minimal.

However, failure to keep bearing lubricated will cause

rapid wear. A wobbly castor wheel usually indicates a

worn bearing.

Loading...

Loading...