21

MAINTENANCE

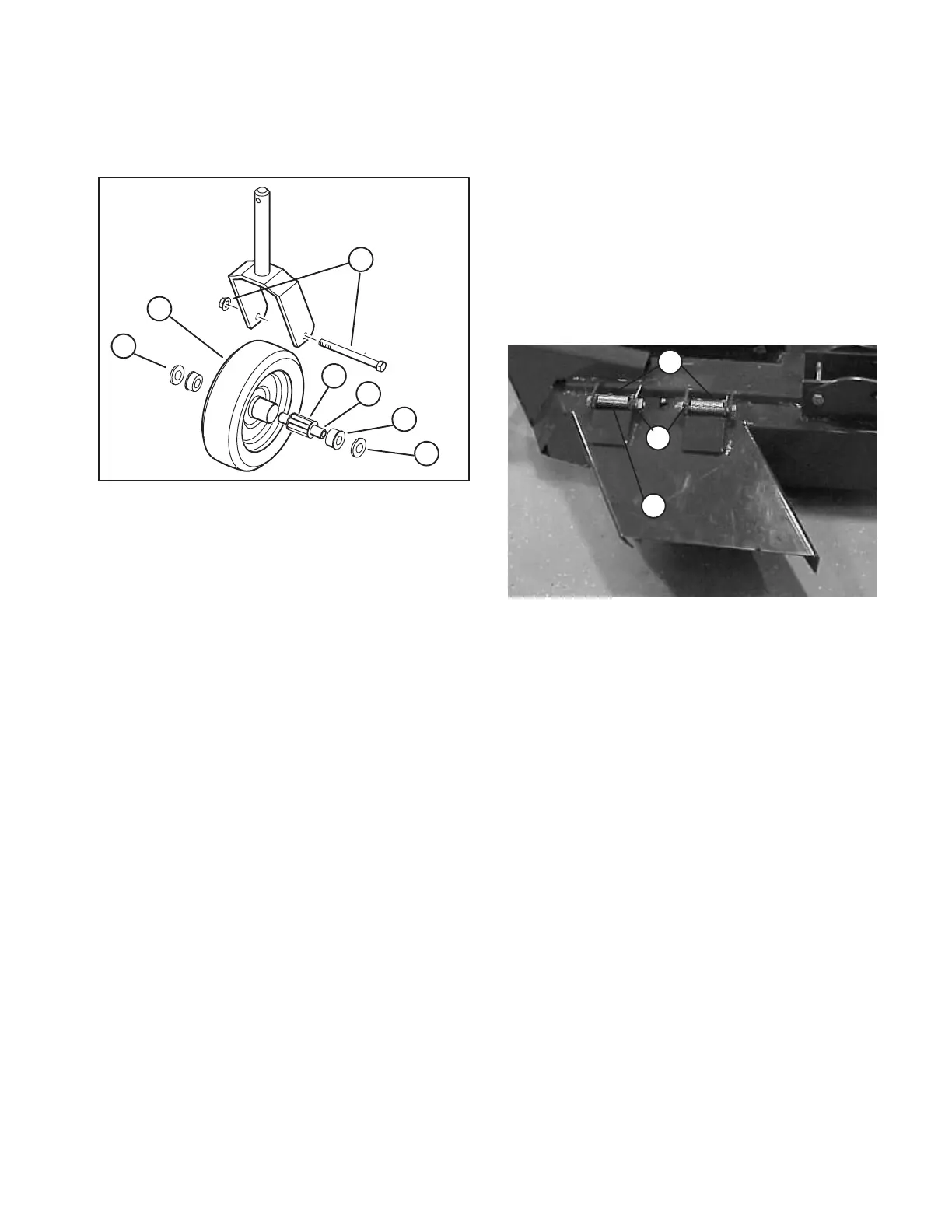

1. Remove locknut from capscrew holding castor

wheel assembly between castor fork. Grasp castor

wheel and slide capscrew out of fork.

2. Pull spanner bushing out of wheel hub.

Figure 34

1. Castor wheel

2. Capscrew & Locknut

3. Bushing (2)

4. Spanner Bushing

5. Roller Bearing

6. Washer (2)

1

2

3

4

5

6

6

3. Remove bushing from wheel hub and allow

bearing to fall out. Remove bushing from opposite side

of wheel hub.

4. Check the bearing, spanner and inside of wheel

hub for wear. Replace defective parts.

5. To assemble the castor wheel, push bushing into

wheel hub. Slide bearing into wheel hub. Push other

bushing into open end of wheel hub to captivate the

bearing inside the wheel hub.

6. Carefully slide spanner through the bushings and

the wheel hub.

7. Install castor wheel assembly between castor fork

and secure in place with capscrew, washers and

locknut.

8. Lubricate castor wheel bearing through grease

fitting, using No. 2 general purpose lithium base

grease.

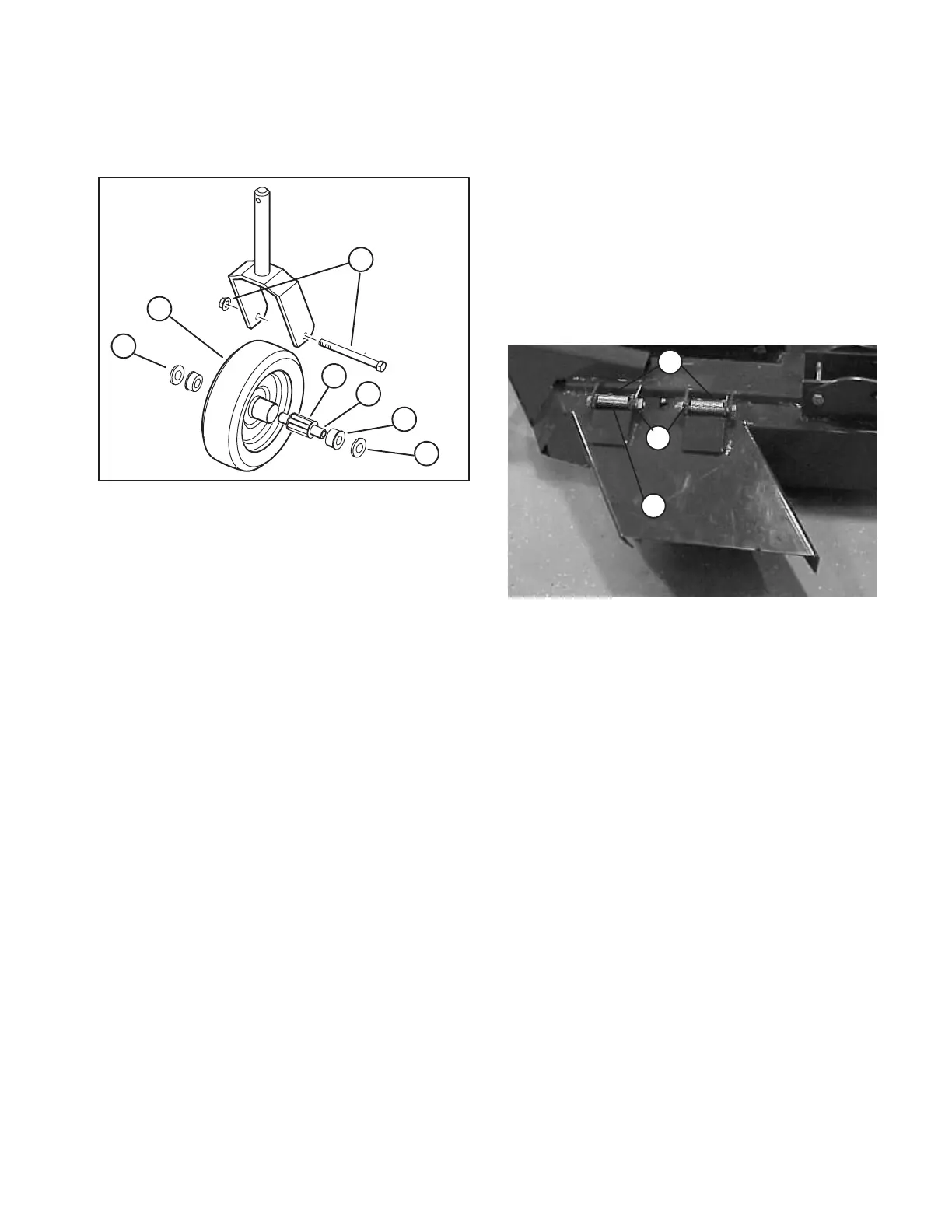

REPLACING GRASS DEFLECTOR (Fig. 35)

1. Position machine on a level surface, raise cutting

unit, engage parking brake, be sure traction pedal is in

neutral position, PTO lever in OFF position, shut engine

OFF and remove key from switch. Block cutting unit to

prevent it from falling accidentally.

2. Remove two capscrews, locknuts and springs

securing deflector mounts to pivot brackets.

3. To remove the pivot brackets, remove carriage

bolts and nuts.

4. Reinstall pivot brackets on top of discharge

opening with carriage bolts and nuts. Head of carriage

bolts must be on inside of cutting unit.

5. Position deflector mounts on pivot brackets and

secure parts together with capscrews, locknuts and

springs. Both locknuts must face each other. Tighten

locknuts until they are flush against deflector pivots.

Figure 35

1. Deflector mounts

2. Pivot brackets

3. Pivot springs

3

2

1

6. Lift deflector and allow it to drop to check spring

tension. Deflector must be held firmly in full downward

position by spring tension. Correct if necessary.

REMOVING CUTTER BLADE (Fig. 36)

The blade must be replaced if a solid object is hit, the

blade is out-of-balance or if the blade is bent. Always

use genuine TORO replacement blades to be sure of

safety and optimum performance. Never use

replacement blades made by other manufacturers

because they could be dangerous.

1. Raise cutting unit to highest position, shut the

engine off and engage the parking brake. Block cutting

unit to prevent it from falling accidentally.

2. Grasp end of blade using a rag or thickly padded

glove. Remove blade bolt, lockwasher, anti-scalp cup

and blade from spindle shaft.

Loading...

Loading...