15

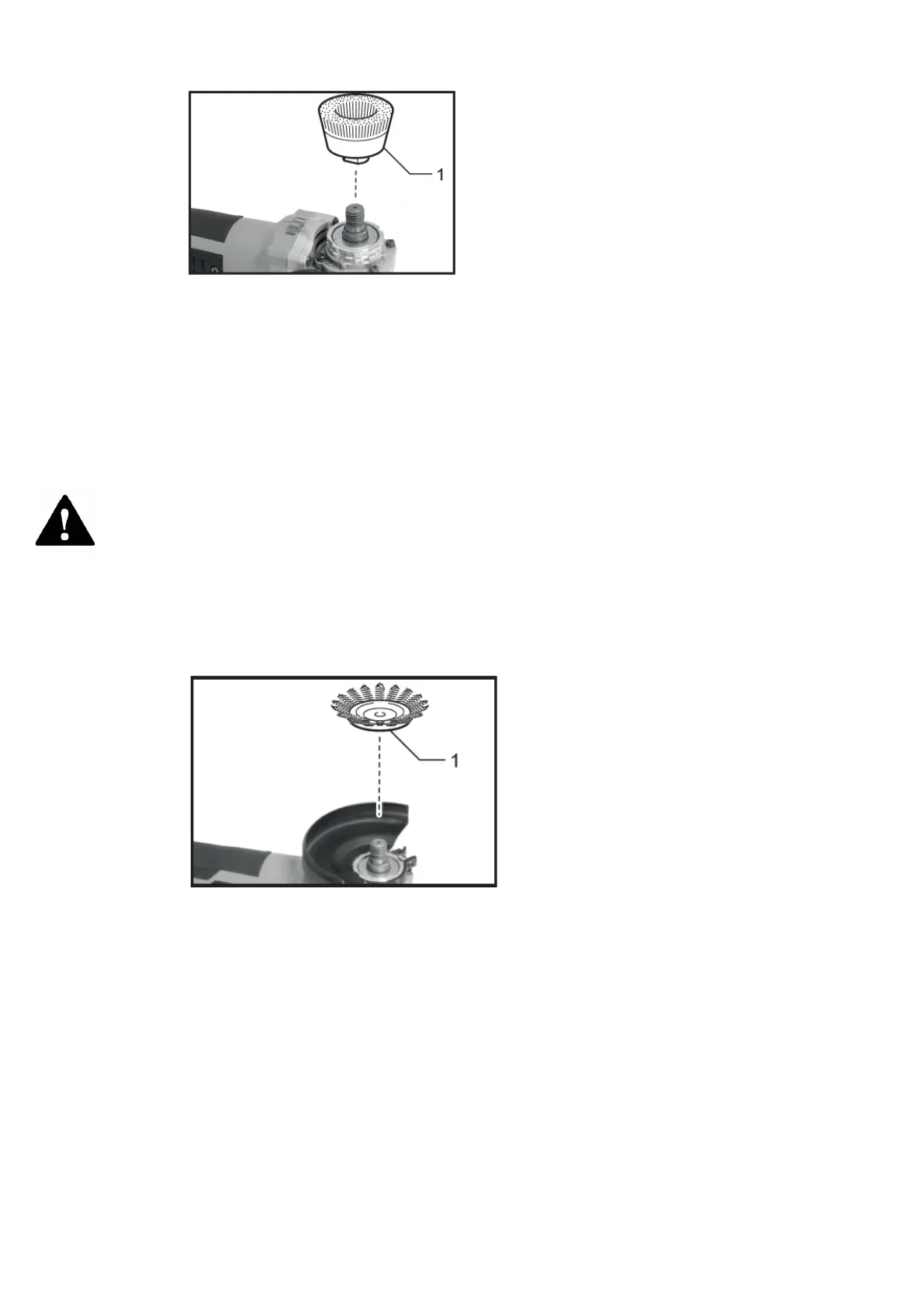

• Remove the battery cartridge from the tool and turn it upside down to allow

easy access to the spindle.

• Remove all accessories from the spindle.

• Thread the wire cup brush onto the spindle and tighten with the wrench

provided.

• When using a brush, avoid applying too much pressure, which causes the wires

to bend too far and break prematurely.

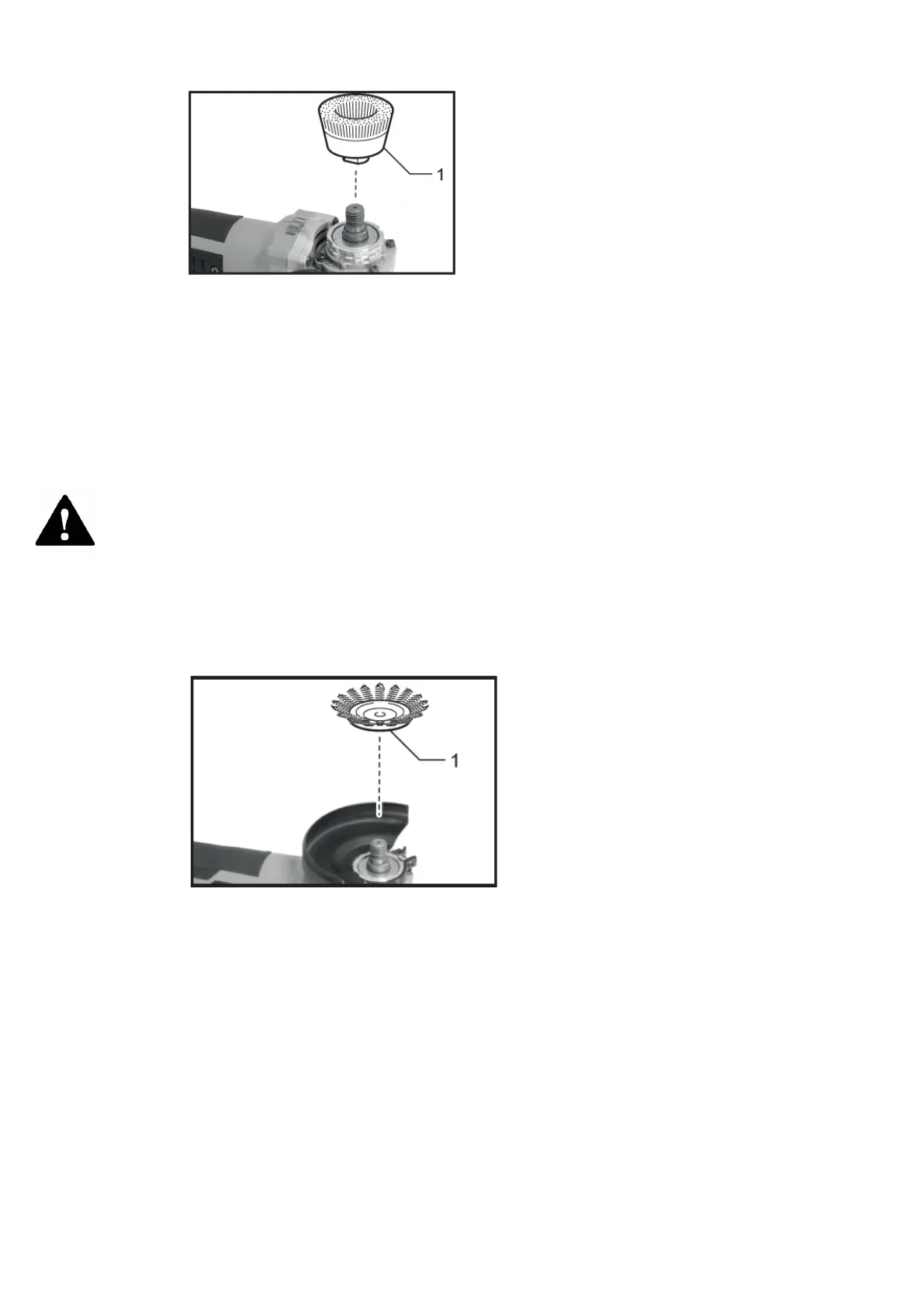

Operation with circular wire brush (optional accessory)

Attention

• Check wire wheel brush operation by running tool without load, making sure no

one is in front of or in line with wire wheel brush.

• Do not use a damaged or unbalanced wire wheel brush. Using a damaged wire

wheel brush could increase the chance of injury from contact with broken wires.

• Always use the guard with wire wheel brushes, making sure the diameter of the

wheel fits inside the guard. The circular brush can break during use and the

guard helps reduce the chance of personal injury.

• Remove the battery cartridge from the tool and turn it upside down to allow

easy access to the spindle.

• Remove all accessories from the spindle.

• Thread the wire wheel brush onto the spindle and tighten with the wrenches.

• When using a circular wire brush, avoid applying too much pressure, which

causes the wires to bend too much and break prematurely.

work tips

• Your tool is useful both for cutting metals; for example, to remove screw heads,

as well as to clean/prepare surfaces; for example, before and after welding

operations.

• Different types of discs will allow the sander to meet various needs. Typically,

grinding wheels/cut-off wheels are available for mild steel, stainless steel,

Loading...

Loading...