E.

INSTALLING

REFRIGERANT

LINES

The

following

steps

are

to

be

considered

when

installing

the

refrigerant lines:

1. Determine

the

most

practical

way

to

run

the

lines.

2. Consider types

of

bends

to

be

made

and

space limita-

tions.

NOTE:

Large

diameter

tubing

sizes

will

be

difficult

to

bend

once

it

has

been

shaped.

3. Determine

the

best

starting

point for

routing

the

refrig-

erant

tubing

--INSIDE OR OUTSIDE

THE

STRUC-

TURE.

4.

Provide a

pull

through

hole of sufficient size

to

allow

both

liquid

and

gas lines

to

clear.

The

location of

this

hole

(if

practical) should

be

just

above

the

wall

plate

which

is

resting

on

the

foundation.

5. Be

sure

the

roll

of

tubing

is

of sufficient length.

6.

Uncoil

the

tubing-

do

not

kink

or dent.

7. Route

the

tubing

making

all required bends

and

prop-

erly secure

the

tubing

before malting final connections.

NOTE:

These

lines

must

be

isolated.

from

the

struc-

ture

and

the

holes

must

be

sealed

weather

tight

after

installation.

F.

FIELD

FABRICATED

INTERCONNECTING

LINES

The

following procedure should

be

used

for connecting tub-

ing

to

the

coil

or

the

outdoor

unit.

1. More information concerning

the

installation ofrefriger-

ant

lines is covered

in

the

Installers

Guide packaged

with

the

outdoor

unit.

Evacuation,

leak

testing

and

brazing procedures

are

included

in

those

instructions

before

starting

the

installation

of

refrigerant lines.

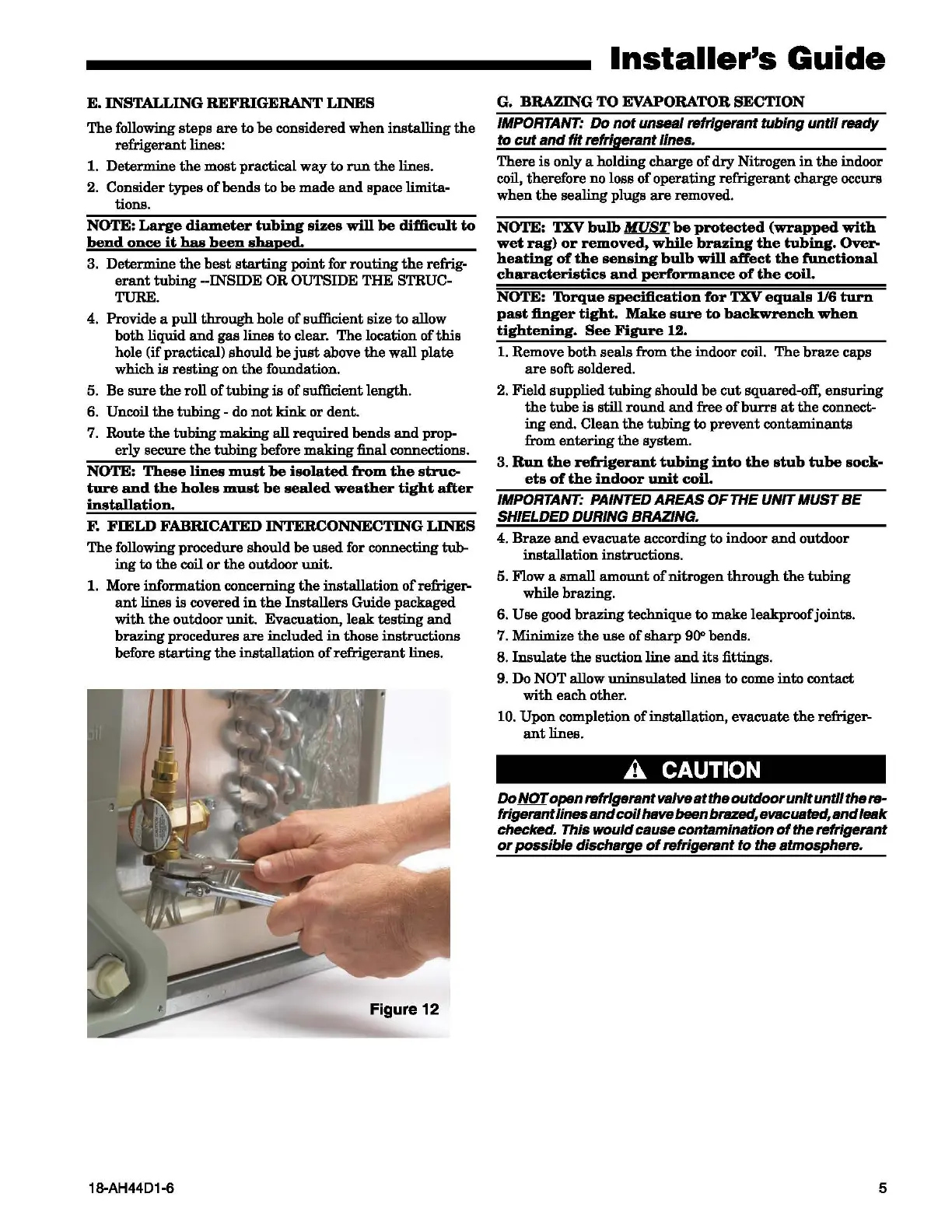

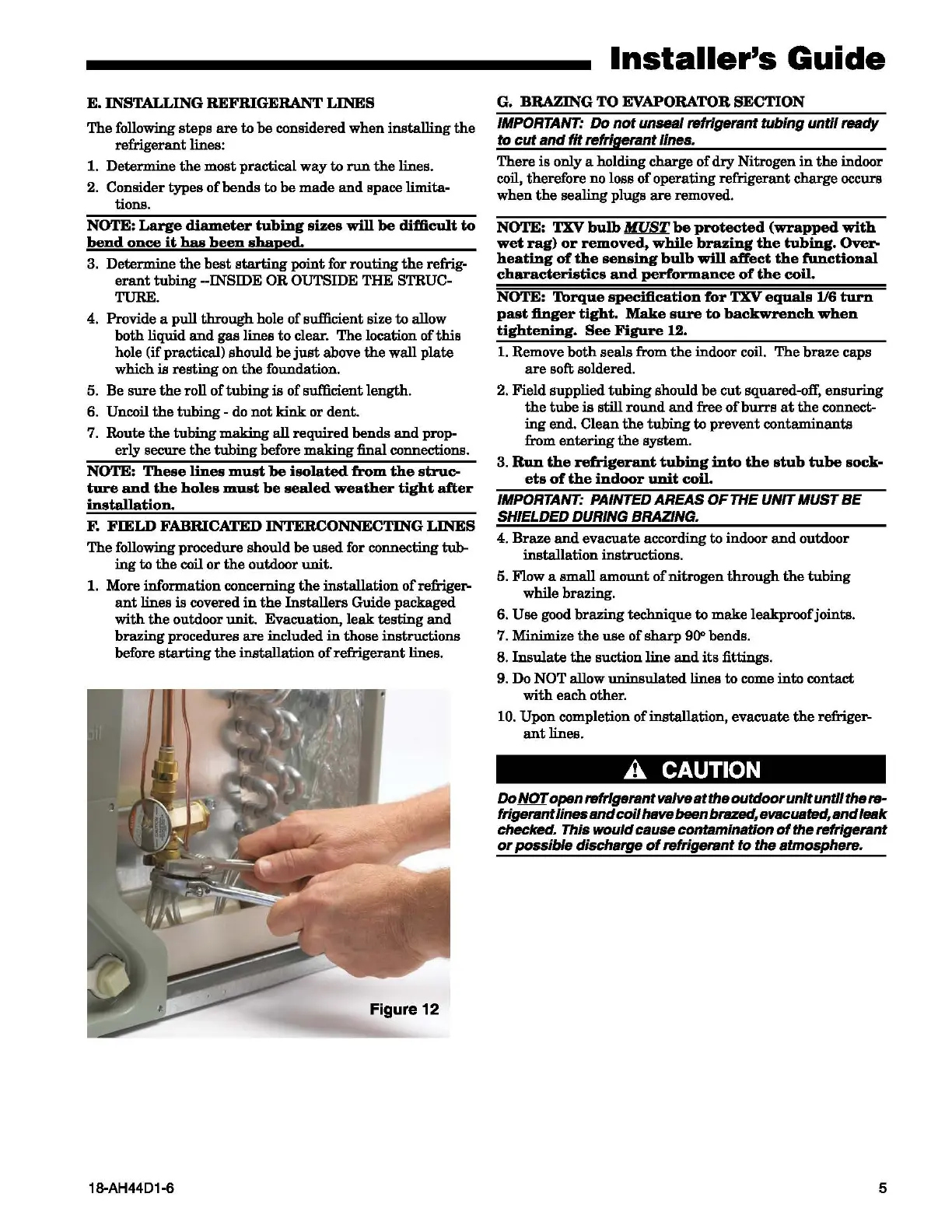

Figure 12

18-AH4401-6

Installer's

Guide

G.

BRAZING

TO

EVAPORATOR

SECTION

IMPORTANT:

Do

not

unseal refrigerant

tubing

until

ready

to

cut

and

fit

refrigerant

lines.

There

is

only a holding charge

of

dry

Nitrogen

in

the

indoor

coil, therefore no loss

of

operating refrigerant charge occurs

when

the

sealing plugs

are

removed.

NOTE:

TXV

bulb

MUST

be

protected

(wrapped

with

wet

rag)

or

removed,

while

brazing

the

tubing.

Over-

heating

of

the

sensing

bulb

will

affect

the

functional

characteristics

and

performance

of

the

coil.

NOTE:

Torque

specification

for

TXV

equals

1/6

turn

past

finger

tight.

Make

sure

to

backwrench

when

tightening.

See

Figure

12.

1.

Remove

both

seals from

the

indoor coil.

The

braze

caps

are

soft soldered.

2. Field supplied

tubing

should

be

cut

squared-off,

ensuring

the

tube

is

still

round

and

free

of

burrs

at

the

connect-

ing

end.

Clean

the

tubing

to

prevent

contaminants

from

entering

the

system.

3.

Run

the

refrigerant

tubing

into

the

stub

tube

sock-

ets

of

the

indoor

unit

coil.

IMPORTANT: PAINTED AREAS

OF

THE UNIT MUST

BE

SHIELDED DURING BRAZING.

4.

Braze

and

evacuate according

to

indoor

and

outdoor

installation instructions.

5.

li1ow

a

small

amount

of

nitrogen

through

the

tubing

while brazing.

6.

Use

good brazing technique

to

make

leakproofjoints.

7. Minimize

the

use

of

sharp

900

bends.

8.

Insulate

the

suction line

and

its

fittings.

9. Do

NOT allow

uninsulated

lines

to

come

into

contact

with

each

other.

10. Upon completion

of

installation, evacuate

the

refriger-

ant

lines.

A CAUTION

Do

Nm

open

refrigerant valve

at

the

outdoor

unit

until

the

re-

frigerant

lines

and

coil

hsvebeenbrszed, evacuated,

and

leak

checked. This

would

cause contamination

of

the

refrigerant

or

possible

discharge

of

refrigerant

to

the

atmosphere.

5

Loading...

Loading...