Maintenance

38 CG-SVX038A-EN

Compressor Operational Noises

Because the scroll compressor is designed to

accommodate liquids (both oil and refrigerant) and solid

particles without causing compressor damage, there are

some characteristic sounds that differentiate it from those

typically associated with a reciprocating compressor.

These sounds, which are described below, are normal and

do not indicate that the compressor is defective.

At low ambient startup: When the compressor starts up

under low ambient conditions, the initial flow rate of the

compressor is low. Under these conditions, it is not

unusual to hear the compressor rattle until the suction

pressure climbs and the flow rate increases. These sounds

are normal and do NOT affect the operation or reliability of

the compressor.

Excessive Amp Draw

Excessive Amp Draw occurs either because the

compressor is operating at an abnormally high

condensing temperature OR because of low voltage at the

compressor motor.

Motor amp draw may also be excessive if the compressor

has internal mechanical damage. In this situation,

vibration and discolored oil can also be observed.

Low Suctions

Continuous low suction pressures are most likely caused

by low evaporator load coupled with a system anomaly.

Symptoms that may accompany low suctions include a

rattling sound emitted from the compressor or an open

motor winding thermostat or discharge thermostat.

Note: Operation of the chiller with saturated suction

temperatures below freezing will cause damage to

the evaporator. If this occurs immediately stop the

machine, diagnose and correct the problem.

Periodic Maintenance

Perform all of the indicated maintenance procedures at the

intervals scheduled. This will prolong the life of the unit

and reduce the possibility of costly equipment failure.

Weekly Maintenance

Once the unit has been operating for about 10 minutes and

the system has stabilized, check operating conditions and

complete the checkout procedures that follow.

• Check compressor oil levels. Oil should be visible in the

sight glass when the compressor is running. Operate

the compressors for a minimum of three to four hours

when checking oil level, and check level every

30 minutes. If oil is not at proper

level after this period,

have a qualified service representative add or remove

oil as required.

• Check suction pressure and disc

harge pressure.

• Check the liquid line sight glasses.

• If operating pressures and sight glass conditions seem

to indicate

refrigerant shortage, measure system

superheat and system sub-cooling.

• If operating conditions indicate an overcharge, slowly

(to mi

nimize oil loss) remove refrigerant at the liquid

line service valve.

• Inspect remote condenser c

oils for cleanliness (CCAR

only) and clean if required. Refer to the condenser

manufacturer’s recommendations.

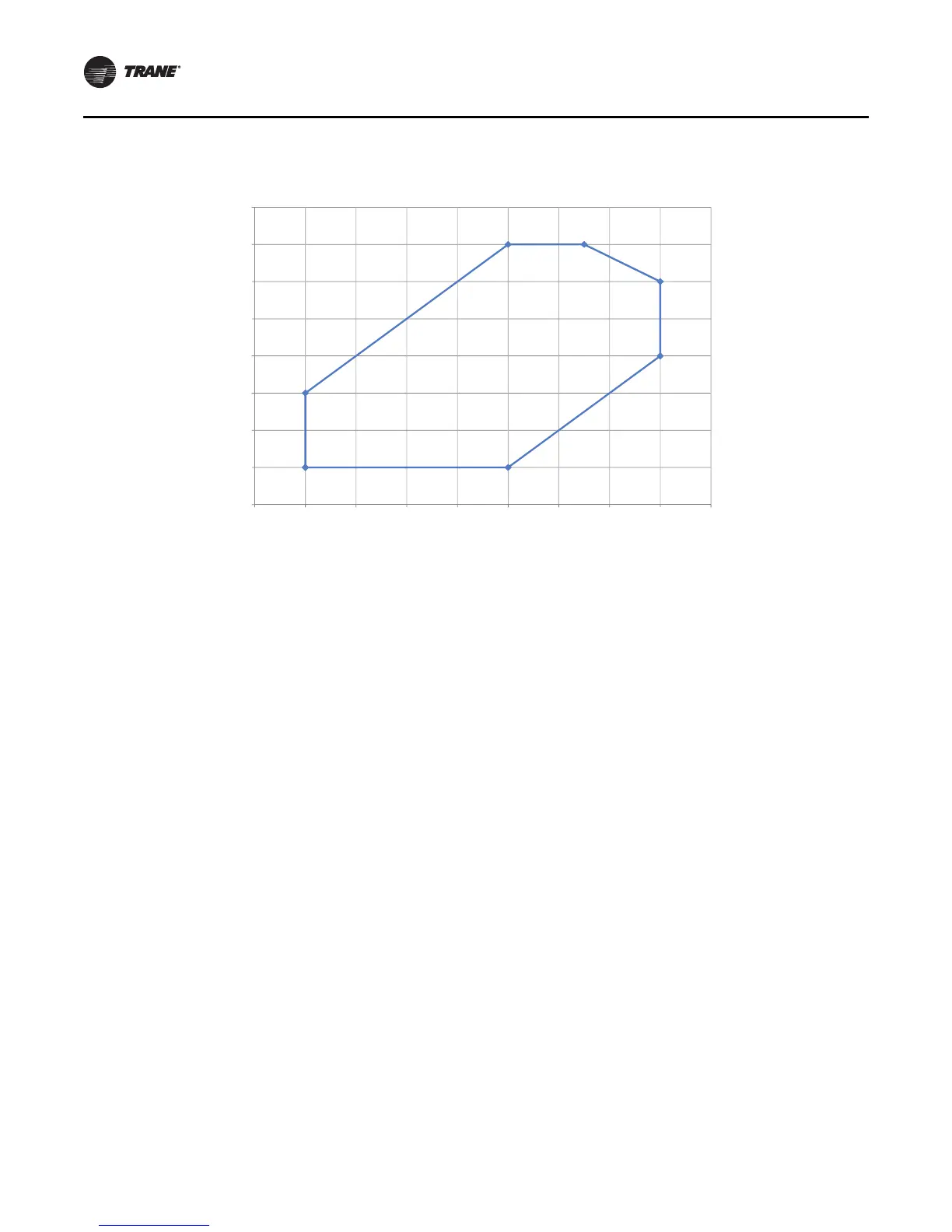

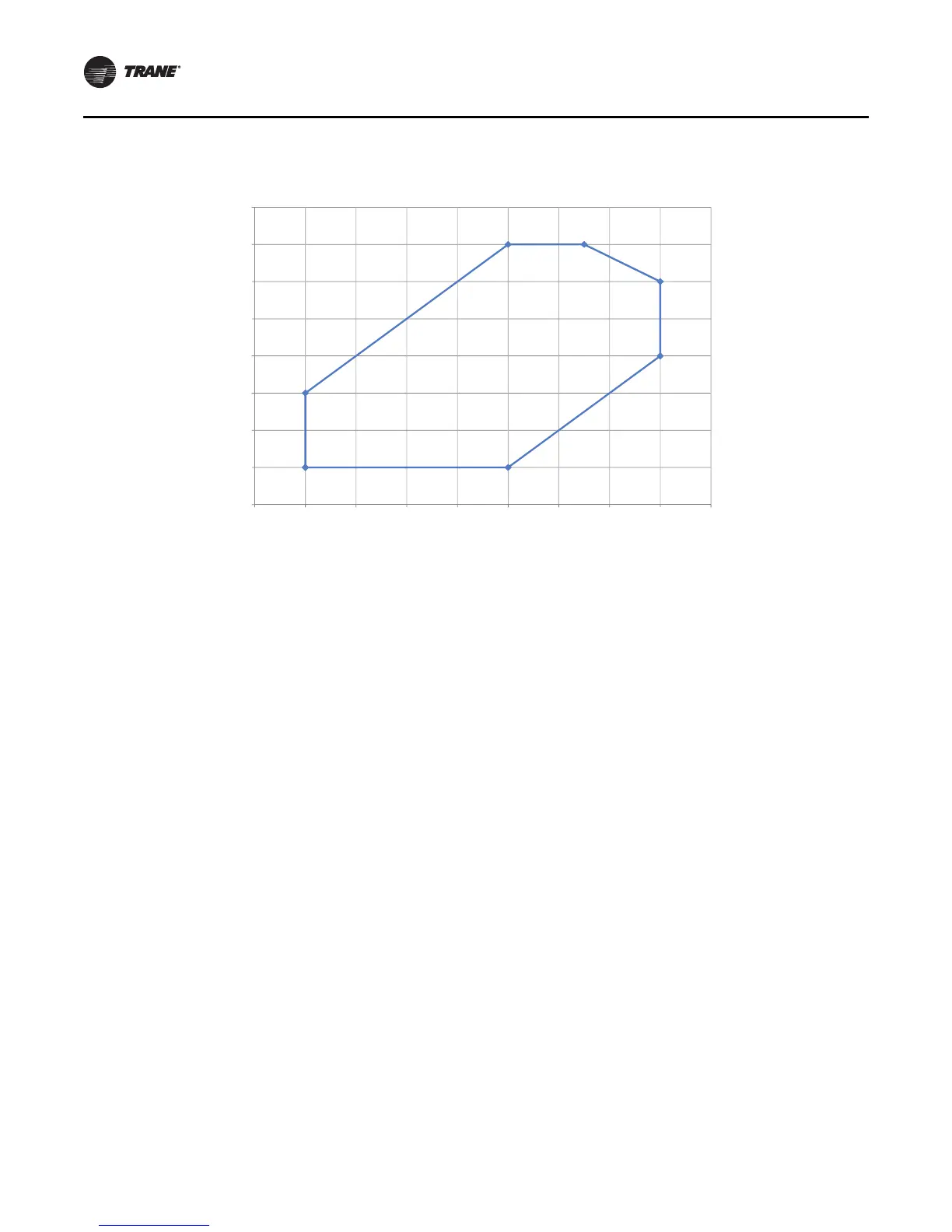

Figure 7. Compressor operating map

70

80

90

100

110

120

130

140

150

-10 0 1020304050607080

Compressor Operating Map

Saturated Condensing Temperature (°F)

Saturated Evaporating Temperature (°F)

Loading...

Loading...