Do you have a question about the Trane S8X1C100M5PSAB and is the answer not in the manual?

Critical warnings about fire, explosion, and electrical shock risks during furnace installation and operation.

Warnings regarding carbon monoxide poisoning due to improper venting or damaged components.

Warning about fire risks, specifically concerning installation on combustible flooring.

Guidelines on electrical safety, bypassing switches, and component interaction.

Precautions for manual lighting, blower door security, and CO risks from improper installation.

Warnings about flammable materials, gas connectors, and filter placement.

Safety measures for high voltage, venting, and electrical disconnect switches.

Cautions on improper voltage, corrosive atmospheres, and overheating risks.

Precautions for sharp edges, wrenches, ignition, and furnace service.

Warnings about freeze protection, water damage, and using the furnace as a construction heater.

Notes on wiring polarity and hot surface components like the igniter.

Critical steps for safe operation of vented appliances to prevent CO poisoning.

Essential safety rules to follow during installation, servicing, and operation of the furnace.

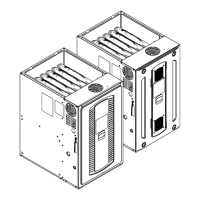

Guidelines for selecting proper installation locations and maintaining required clearances.

Diagrams and notes for gas piping connections in upflow furnace orientations.

Diagrams and notes for gas piping connections in downflow furnace orientations.

Diagrams for gas piping in horizontal left orientation (top and bottom outlets).

Diagrams for gas piping in horizontal right orientation (top and bottom outlets).

Steps for adjusting manifold pressure for 1st and 2nd stage heating.

Guidelines for supplying combustion air in confined spaces, including outdoor and indoor air options.

Diagrams illustrating thermostat wiring for single-stage and two-stage heating systems.

Steps for preliminary checks before startup, including gas leak detection.

Procedures for checking limit switches and safety controls during initial startup.

List and explanation of alarm error codes and their corresponding explanations.

Table relating furnace airflow (CFM) to external static pressure for specific models.

Comprehensive list of alarm error codes and their corresponding explanations.

Detailed sequence of operations for 1st stage gas heating, including safety checks and ignition.

Detailed sequence for 2nd stage gas heating operation on S8X2 models.

Sequence of operations for single stage cooling mode.

Sequence of operations for two stage cooling mode.

Sequence of operations for single stage heat pump mode.

Sequence of operations for two stage heat pump mode.

Loading...

Loading...