ENGLISH

66

www.trapp.com.br

Image merely illustrative.

Correct side for

sharpening

Fig. 9

Hammers

Some shredder models are provided with mobile

hammers. Hammers are provided with 4 dented

corners which position can be changed as they

wear out (gure 10).

To change position of hammers or to substitute

them, remove the axle (1) counterpins and the lock

(2) (gure 11). Remove them through the opening

in the green crop feeder. When removing them,

to avoid unbalance and vibration of the shredder,

always observe the position of the separating rings.

Be careful not to mix the hammer sets (sides).

Replace or change the mobile hammer side on a

stepwise way; after completing an axle, proceed to

the following one:

Note: perform this procedure with the equipment off, in

case of excessive vibration when mounting the hammers,

turn the machine off and check the mobile hammers

position and correct if it is wrong, if vibration persists

contact an Authorized TRAPP Technical Assistant.

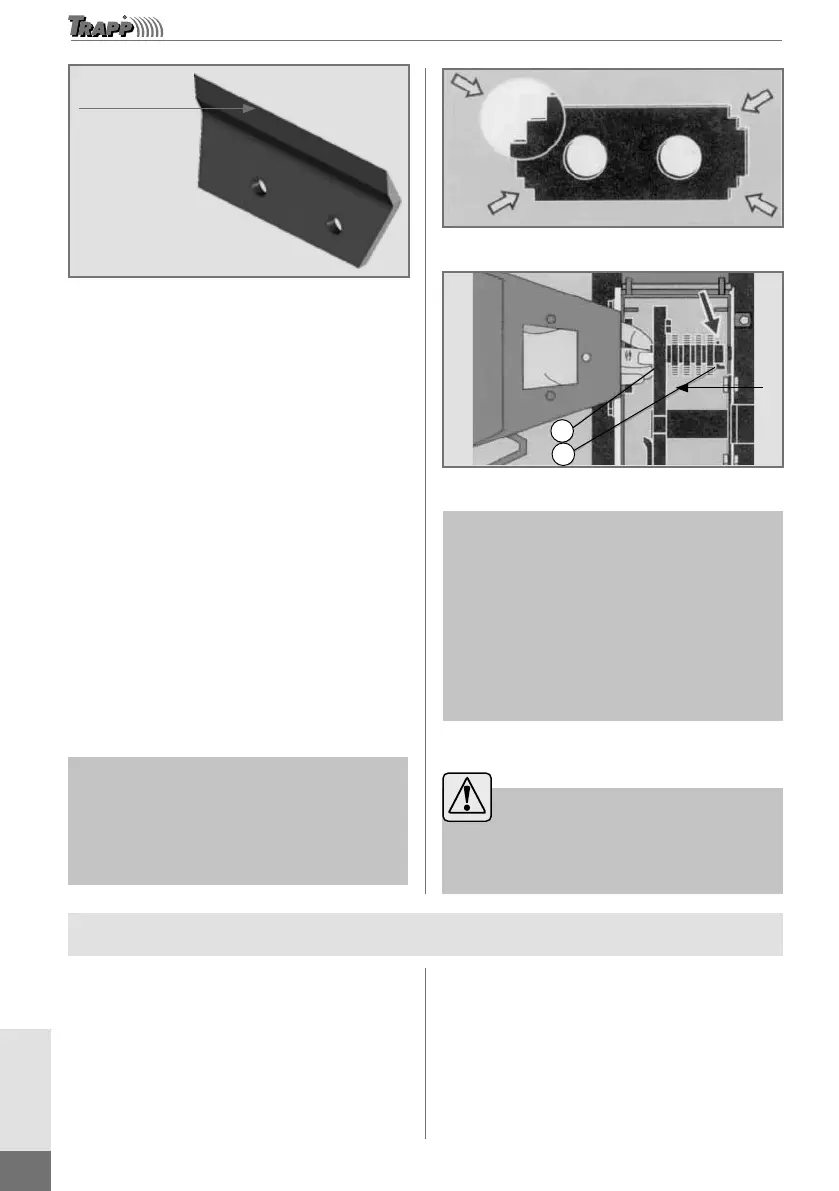

Image merely illustrative.

Fig. 10

Image merely illustrative.

Direction to remove the axles.

1

2

Fig. 11

Tichtening of screws

Due to the impact and constant vibrations

caused by chopping and grinding of

materials, it is a natural tendency for

screws to loosen.

Check them periodically, and if necessary

tighten the loose screws. Be careful not to

overtighten as they may strip.

Attention!

Always turn off shredder and unplug it before

servicing or cleaning.

Periodic Maintenance Plan - Gasoline Motor

In the rst ve hours:

Substitute the crankcase oil.

After every ve hours or daily:

Check the oil level.

Clean the vhole equipment.

After every 25 hours:

Substitute the crankcase oil.

Air lter maintenance.

After every 50 hours:

Substitute the air lter.

After every 100 hours:

Substitute the spark plug.

Loading...

Loading...