TRICKSTUFF® GMBH

SCHWABENMATTEN 17A

79292 PFAFFENWEILER

GERMANY

TECH-SUPPORT@TRICKSTUFF.DE SERVICE MANUAL – DIRETTISSIMA/MAXIMA PUMP V2024_02. PAGE 18 OF 27

2. In the next step the reservoir cap bolts will be mounted.

Warning: If not carefully mounted according to this process, you can damage the membrane.

Please follow these steps:

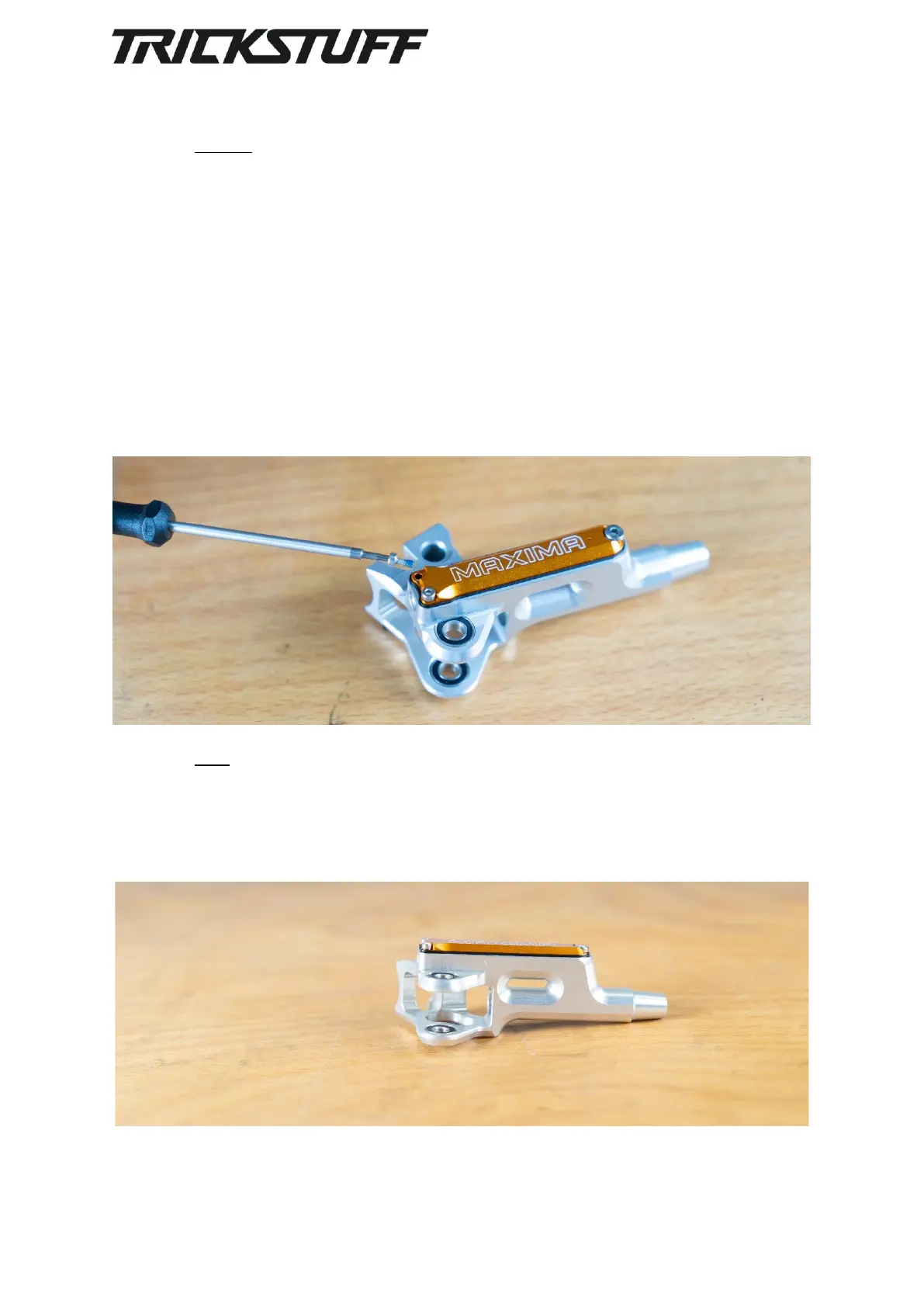

1. Apply medium strength thread locker (e.g. Loctite 243) to the M3 bolt and apply 3-4

clockwise turns with a HEX2mm key. Torquing down happens a little later.

2. Apply medium strength thread locker (e.g. Loctite 243) to the M2 bolt and apply 3-4

clockwise turns with a HEX1.5mm key. Torquing down happens a little later.

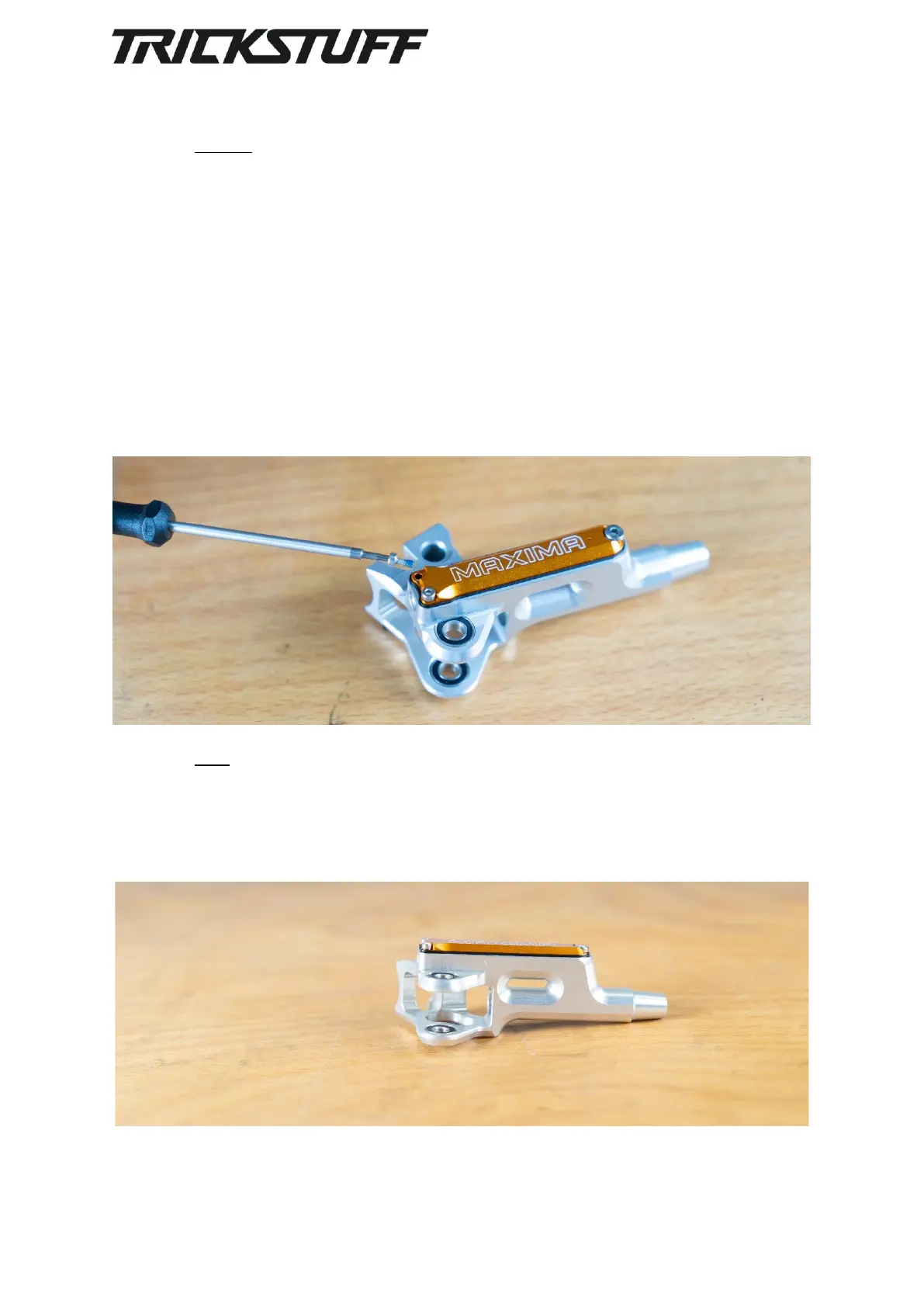

3. Check correct seating of membrane sealing lip around the cap. It should not show gaps or

be folded under the cap.

4. Apply torque to the M3 bolt, until you can feel that you are just starting to compress the

rubber membrane. From this point, add ¼ turn more. Adding more torque to the screw

can damage the seal.

5. Apply torque to both M2 bolts in the same way, one after the other. Screw in until you feel

an increase in torque resistance (=compression of the seal), then add ¼ turn to that. The

membrane and its sealing lip should be equally compressed all around now.

Note: To check whether the assembly of the membrane was successful, you can apply

negative and positive pressure (alternating) to the syringe during bleeding after the service. If

the seal is damaged, drawing a vacuum at the brake pump with the bleeding syringe will result

in air intake, or positive pressure can result in oil exit. In this case, take off the membrane

again and check it for damages optically, then give the assembly another try.

Loading...

Loading...