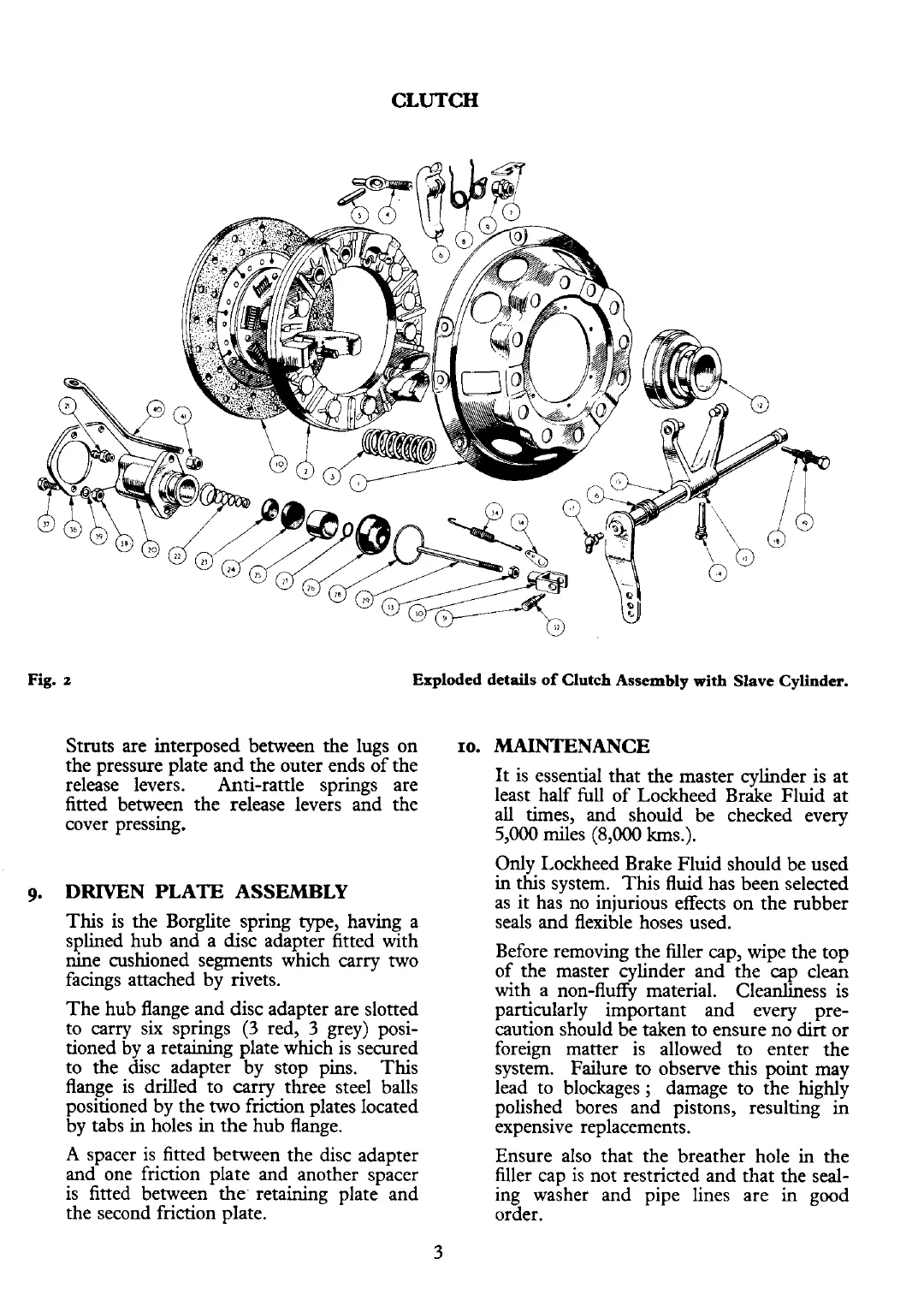

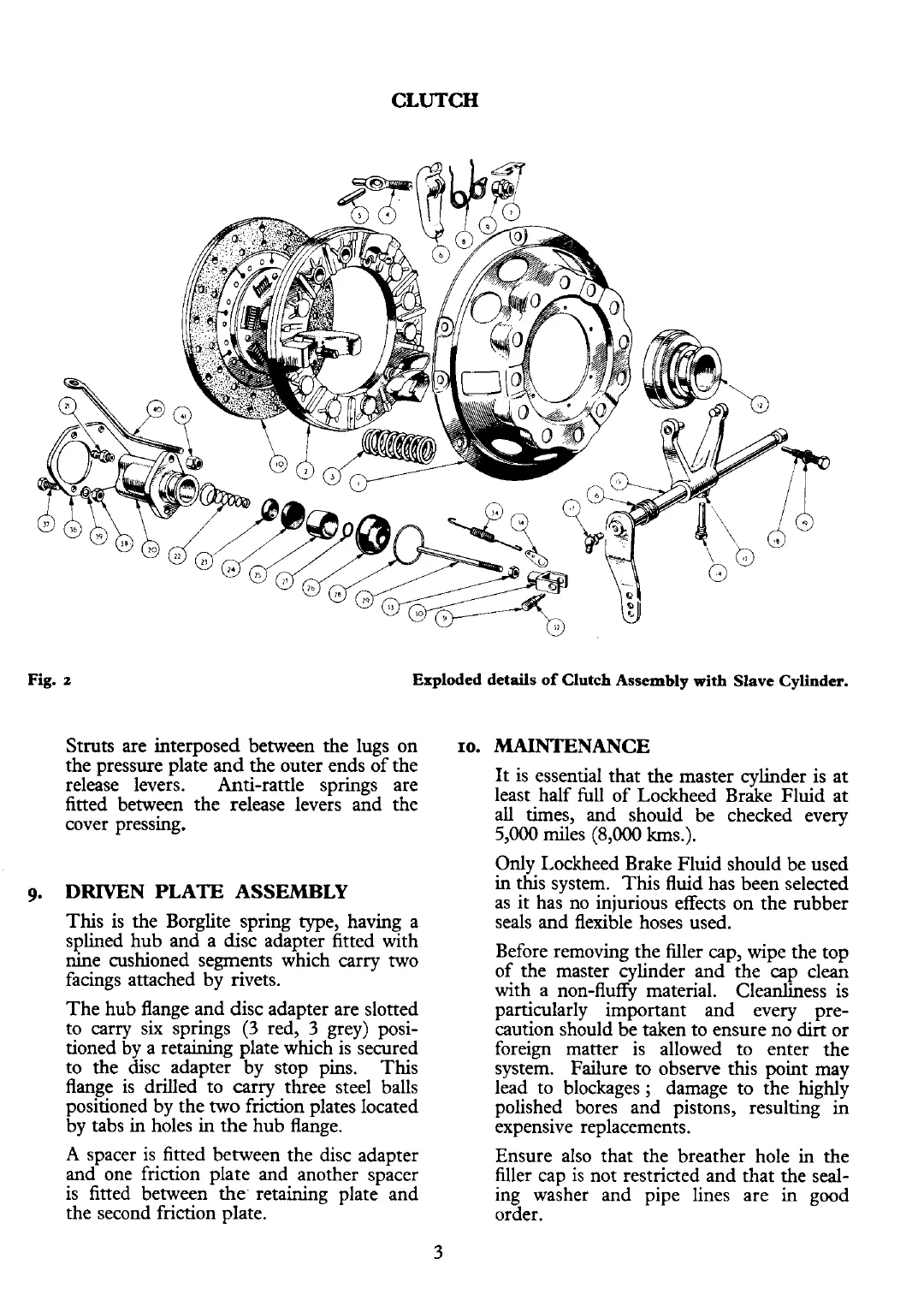

CLUTCH

Fig.

z

Exploded details

of

Clutch Assembly with Slave Cylinder.

Struts are interposed between the lugs on

the pressure plate and the outer ends of the

release levers. Anti-rattle springs are

fitted between the release levers

and the

cover pressing.

9.

DRIVEN

PLATE ASSElMBLY

This is the Borglite spring type, having a

splined hub and a disc adapter fitted with

nine cushioned segments which carry two

facings attached by rivets.

The hub flange and disc adapter are slotted

to carry six springs

(3

red,

3

grey) posi-

tioned by a retaining plate which is secured

to

the

disc adapter by stop pins.

This

flange is drilled to carry three steel balls

positioned by the two friction plates located

by tabs in holes in the hub flange.

A

spacer is fitted between the disc adapter

and one friction plate and another spacer

is fitted between the. retaining plate and

the second friction plate.

ro.

MAINTENANCE

It is essential that the master cylinder is at

least half

full

of Lockheed Brake Fluid at

all times, and should be checked every

5,000

miles

(8,000

km.).

Only Lockheed Brake Fluid should be used

in this system. This fluid has been selected

as it has no injurious effects on the rubber

seals and flexible hoses used.

Before removing the

filler cap, wipe the top

of the master cylinder and the cap clean

with a non-fluffy material. Cleanliness is

particularly important and every pre-

caution should be taken to ensure no dirt or

foreign matter is allowed to enter the

system. Failure to observe this point may

lead to blockages

;

damage to the highly

polished bores and pistons, resulting in

expensive replacements.

Ensure also that the breather hole in the

filler cap is not restricted and that the seal-

ing washer and pipe lines are

in

good

order.

Loading...

Loading...