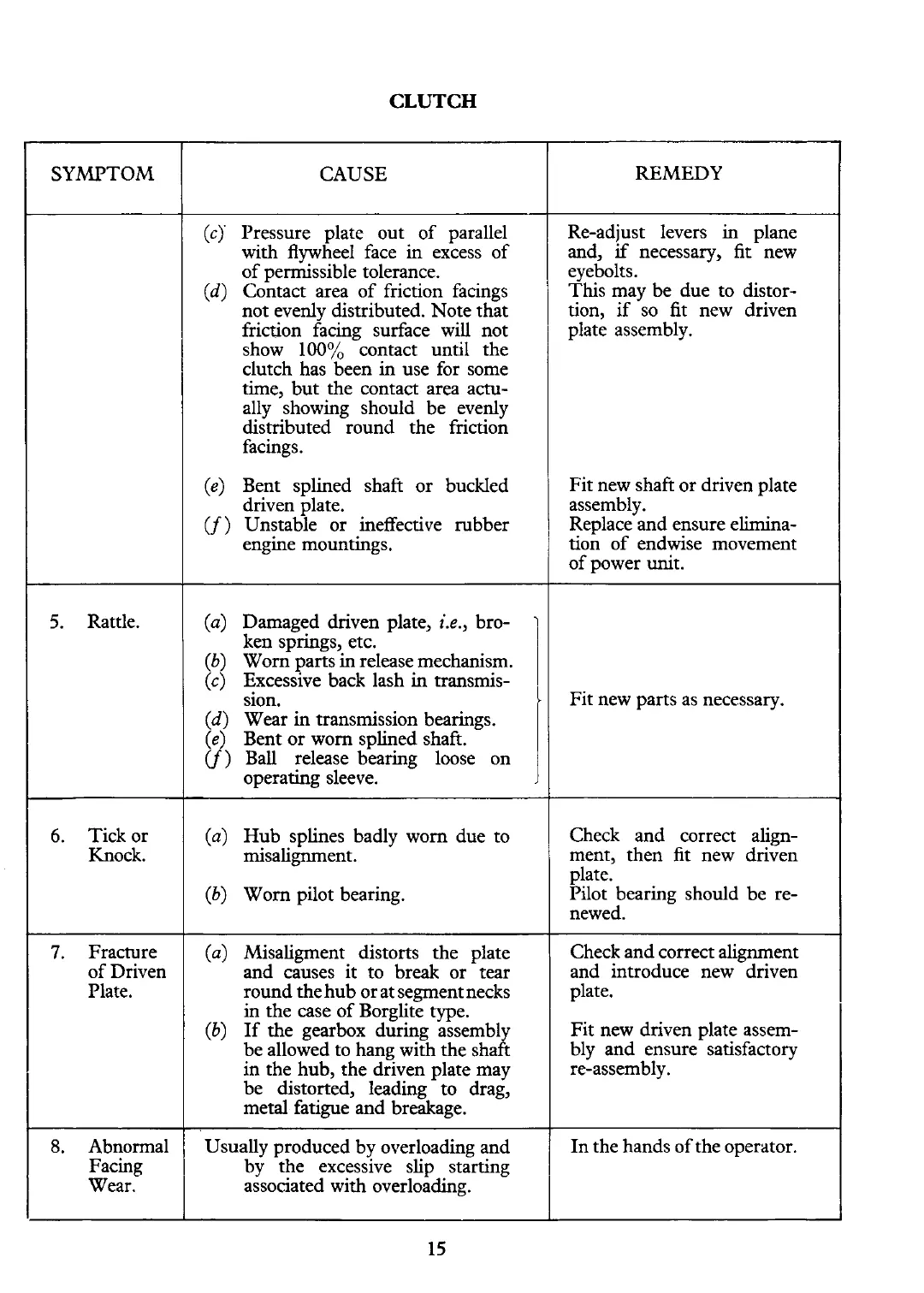

CLUTCH

SYMPTOM

5.

Rattle.

6.

Tick or

Knock.

7.

Fracture

of Driven

Plate.

8.

Abnormal

Facing

Wear.

CAUSE

(c)'

Pressure plate out of parallel

with flywheel face in excess of

of permissible tolerance.

(d)

Contact area of friction facings

not evenly distributed. Note that

friction facing surface will not

show

100%

contact until the

clutch has been in use for some

time, but the contact area actu-

ally showing should be evenly

distributed round the friction

facings.

(e)

Bent splined shaft or buckled

driven plate.

(f)

Unstable or ineffective rubber

engine mountings.

(a)

Damaged driven plate,

i.e.,

bro-

ken springs, etc.

(b)

Worn parts in release mechanism.

(c)

Excessive back lash in transmis-

sion.

(d)

Wear in transmission bearings.

(e)

Bent or worn splined shaft.

Cf)

Ball release bearing loose on

operating sleeve.

(a)

Hub splines badly worn due to

misalignment.

(b)

Worn pilot bearing.

(a)

Misaligment distorts the plate

and causes it to break or tear

round the hub or at segment necks

in the case of Borglite type.

(b)

If the gearbox during assembly

be allowed to hang with the shaft

in the hub, the driven plate may

be distorted, leading to drag,

metal fatigue and breakage.

Usually produced by overloading and

by the excessive slip starting

associated with overloading.

REMEDY

Re-adjust levers in plane

and,

if

necessary,

fit

new

eyebolts.

This may be due to distor-

tion, if so fit new driven

plate assembly.

Fit new shaft or driven plate

assembly.

Replace and ensure elimina-

tion of

endwise movement

of power unit.

Fit new parts as necessary.

Check and correct align-

ment, then

fit

new driven

plate.

Pilot bearing should be re-

newed.

Check and correct alignment

and introduce new driven

plate.

Fit new driven plate assem-

bly and ensure satisfactory

re-assembly.

In

the hands of the operator.

Loading...

Loading...