FRAME

UNIT

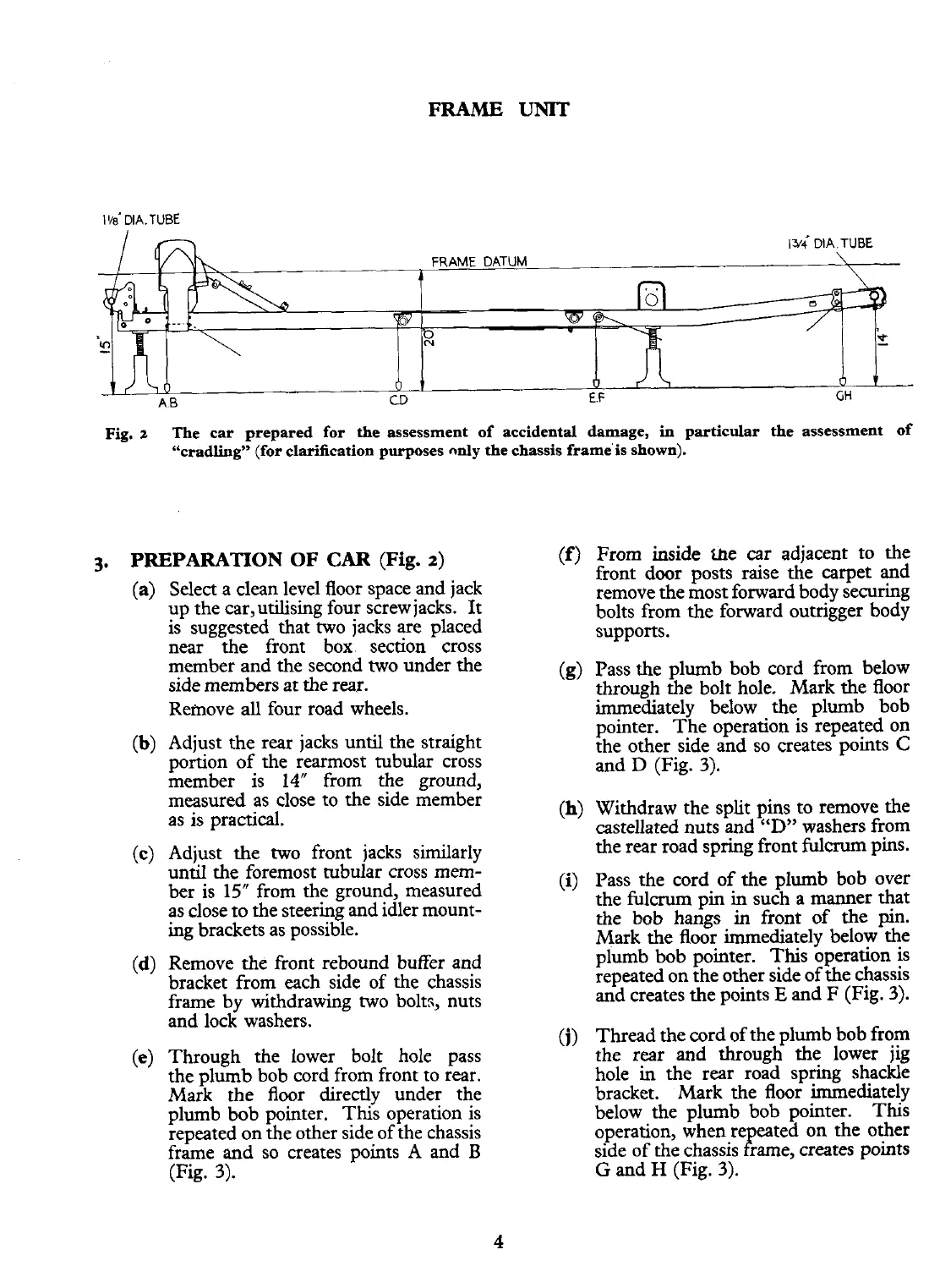

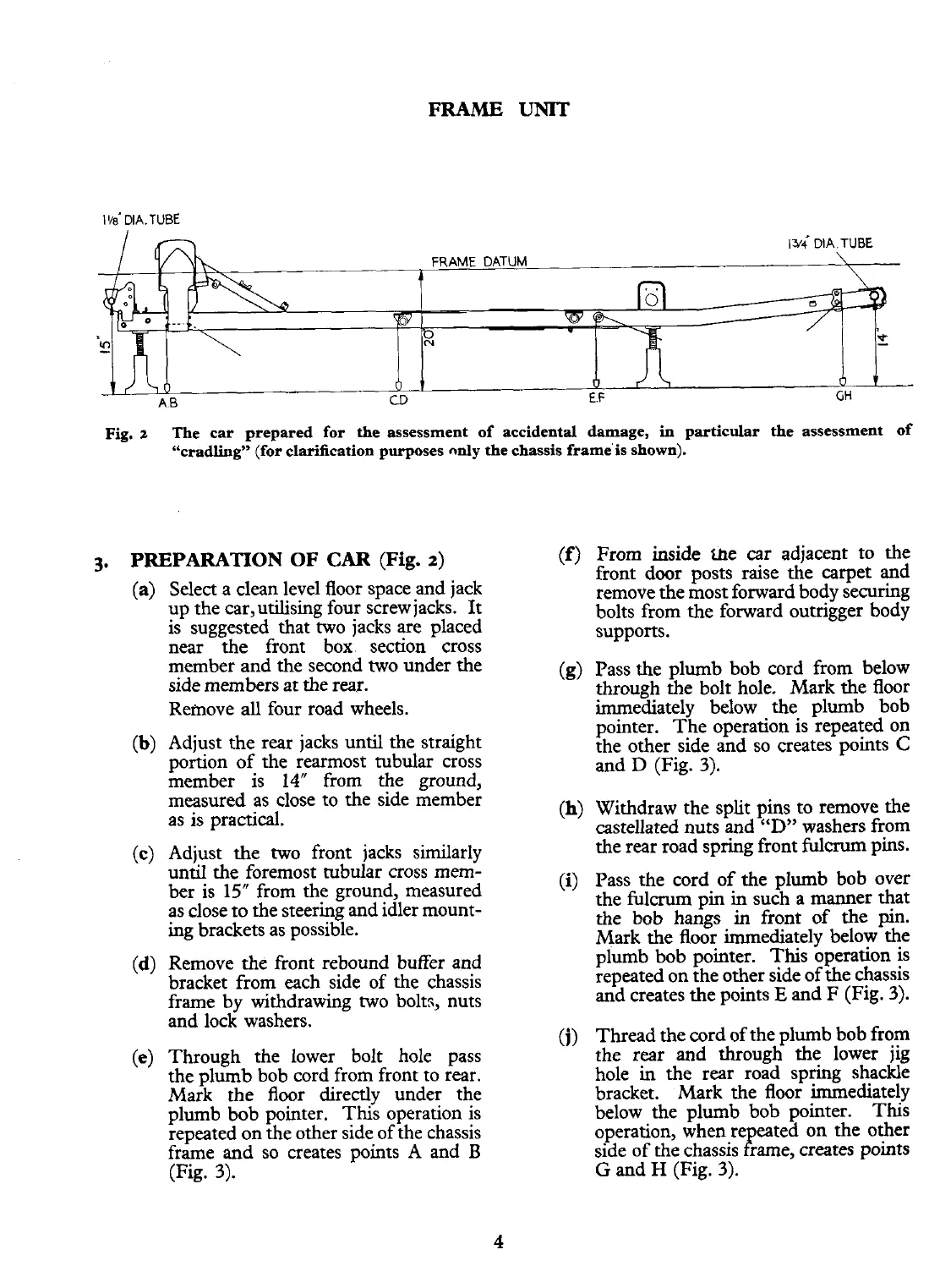

Fig.

z

The car prepared for the assessment of accidental damage,

in

particular the assessment of

"cradling" (for clarification purposes

nnly

the chassis frame'is shown).

3.

PREPARATION OF

CAR

(Fig.

2)

(a)

Select a clean level floor space and jack

up the car,utilising four screw jacks. It

is suggested that two jacks are placed

near the front box section cross

member and the second two under the

side members at the rear.

Reinove all four road wheels.

(b)

Adjust the rear jacks until the straight

portion of the rearmost tubular cross

member is 14" from the ground,

measured as close to the side member

as is practical.

(c)

Adjust the two front jacks similarly

until the foremost tubular cross mem-

ber is

15"

from the ground, measured

as close to the steering and idler mount-

ing brackets as possible.

(d)

Remove the front rebound buffer and

bracket from each side of the chassis

frame by withdrawing two bolts, nuts

and lock washers.

(e)

Through the lower bolt hole pass

the plumb bob cord from front to rear.

Mark the floor directly under the

plumb bob pointer. This operation is

repeated on the other side of the chassis

frame and so creates points A and

B

(Fig.

3).

(f)

From inside ule car adjacent to the

front door posts raise the carpet and

remove the most forward body securing

bolts from the forward outrigger body

supports.

(g)

Pass the plumb bob cord from below

through the bolt hole. Mark the floor

immediately below the plumb bob

pointer. The operation is repeated on

the other side and so creates points

C

and

D

(Fig.

3).

(h)

Withdraw the split pins to remove the

castellated nuts and

"D"

washers from

the rear road spring front fulcrum pins.

(i)

Pass the cord of the plumb bob over

the fulcrum pin in such a manner that

the bob hangs in front of the

pin.

Mark the floor immediately below the

plumb bob pointer. This operation is

repeated on the other side of the chassis

and creates the points

E

and

F

(Fig.

3).

(j)

Thread the cord of the plumb bob from

the rear and through the lower jig

hole in the rear road spring shackle

bracket. Mark the floor immediately

below the plumb bob pointer. This

operation, when re eated on the other

G

and

H

(Fig.

3).

P

side of the chassis rame, creates points

Loading...

Loading...