WHEELS

AND

TYRES

SOFT

CUSHION

RUBBER

TREAD

I

BREAKER

CASING

BEAD

WIRES

Fig.

I

Tyre

Construction.

Construction

of

Tyre

One of the principal functions of the tyres

fitted to a car is to eliminate high frequency

vibrations. They do this by virtue of the fact

that the unsprung mass of each tyre-the part

of the tyre

in

contact with the ground-is very

small.

Tyres must be flexible and responsive. They

must also be strong and tough to contain the

air

pressure, resist damage, give long mileage,

transmit driving and braking forces, and at the

same time provide road grip, stability, and good

steering properties.

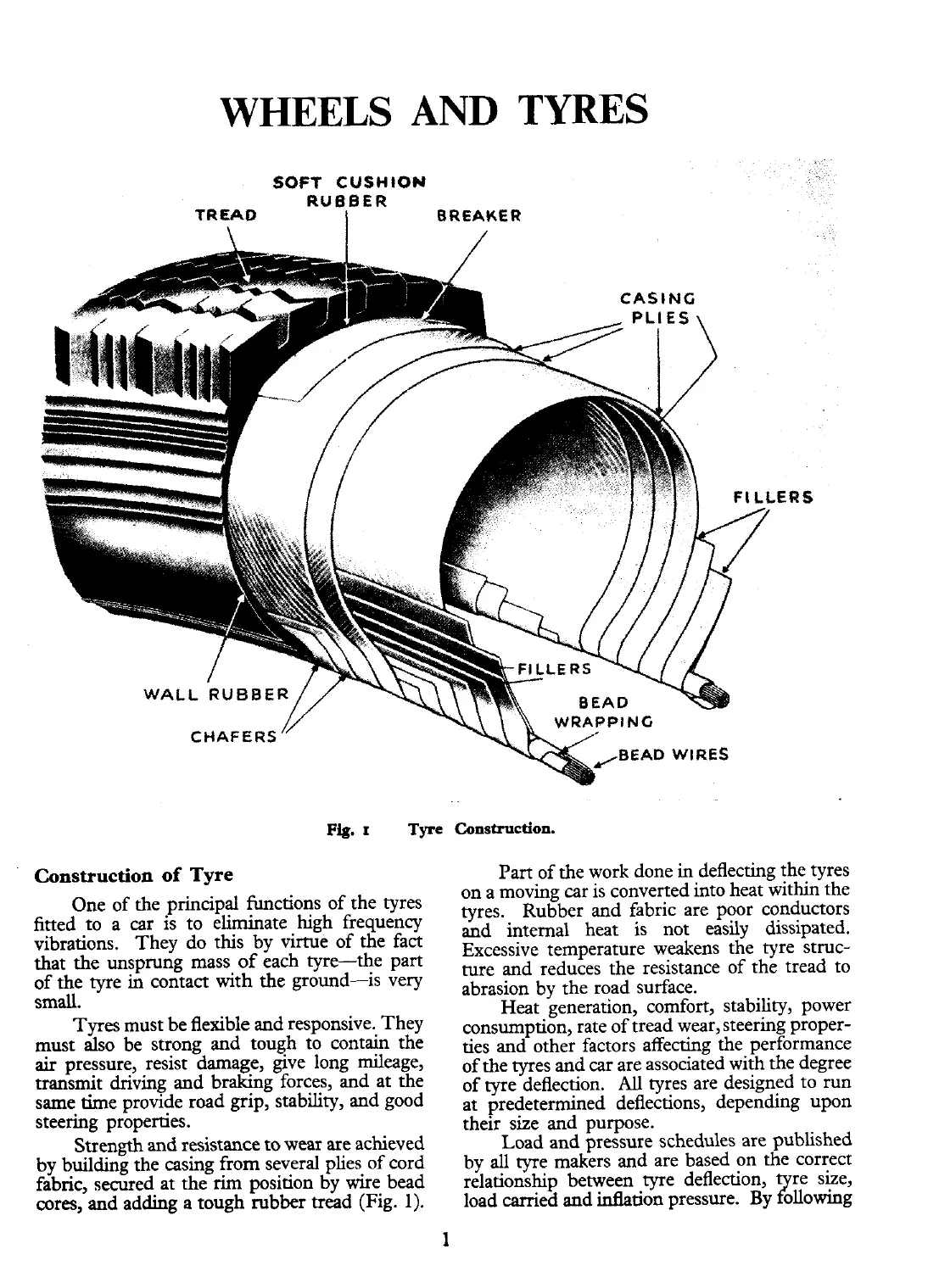

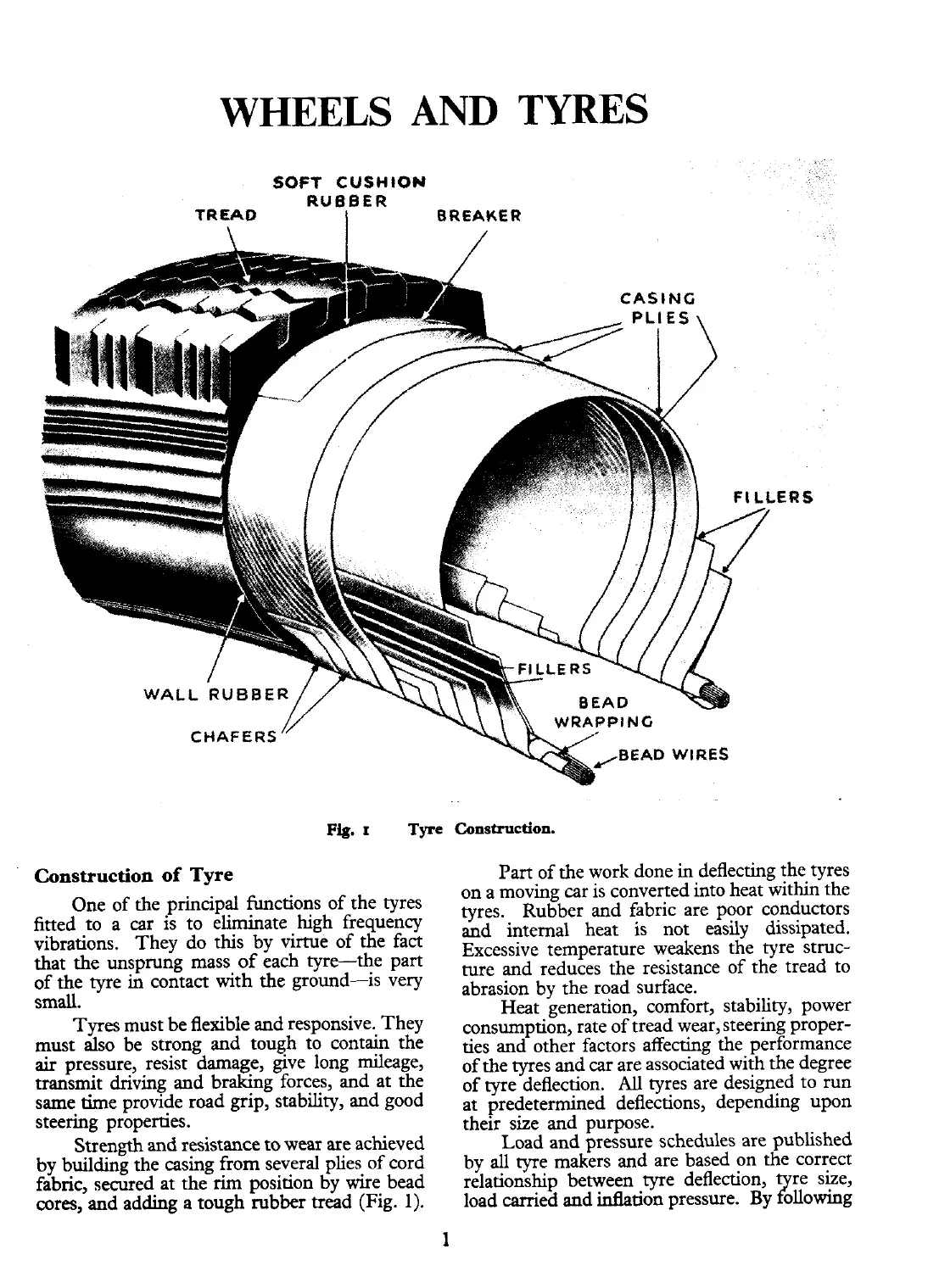

Strength and resistance to wear are achieved

by building the casing from several plies of cord

fabric, secured at the

rim

position by wire bead

cores, and adding a tough rubber tread (Fig.

1).

Part of the work done

in

deflecting the tyres

on a moving car is converted into heat within the

tyres. Rubber and fabric are poor conductors

and internal heat is not easily dissipated.

Excessive temperature weakens the tyre struc-

ture and reduces the resistance of the tread to

abrasion by the road surface.

Heat generation, comfort, stability, power

consumption, rate of tread wear, steering proper-

ties and other factors affecting the performance

of the tyres and car are associated with the degree

of tyre deflection.

All

tyres are designed to run

at predetermined deflections, depending upon

their size and purpose.

Load and pressure schedules are published

by all tyre makers and are based on the correct

relationship between tyre deflection,

r"

load carried and inflation pressure.

By

ollomg

Loading...

Loading...