ELECTRICAL

EQUIPMENT

the regulator core, due to the shunt or

voltage winding, becomes sufficiently strong

to attract the armature to the core. This

causes the contacts to open, thereby insert-

ing the resistance in the generator field

circuit.

The consequent reduction in the generator

field current lowers the generator terminal

voltage, and this, in

turn,

weakens the

magnetic

flux

in the regulator core. The

armature therefore returns to its original

position, and the contacts closing allow the

generator voltage to rise again to its

maximum value. This cycle is then repeated

and an oscillation of the armature is

maintained.

As the speed of the generator rises above

that at which the regulator comes into

operation, the periods of contact separation

increase in length and, as a result, the

mean value of the generator voltage under-

goes practically no increase once this

regulating

speed has been attained.

The series or current winding provides a

compensatiori on this system of control, for

if the control were arranged entirely on the

basis of voltage there would be a risk of

seriously overloading the generator when

the battery was in a low state of charge,

articularly if the lamps were simultaneous-

&

in use.

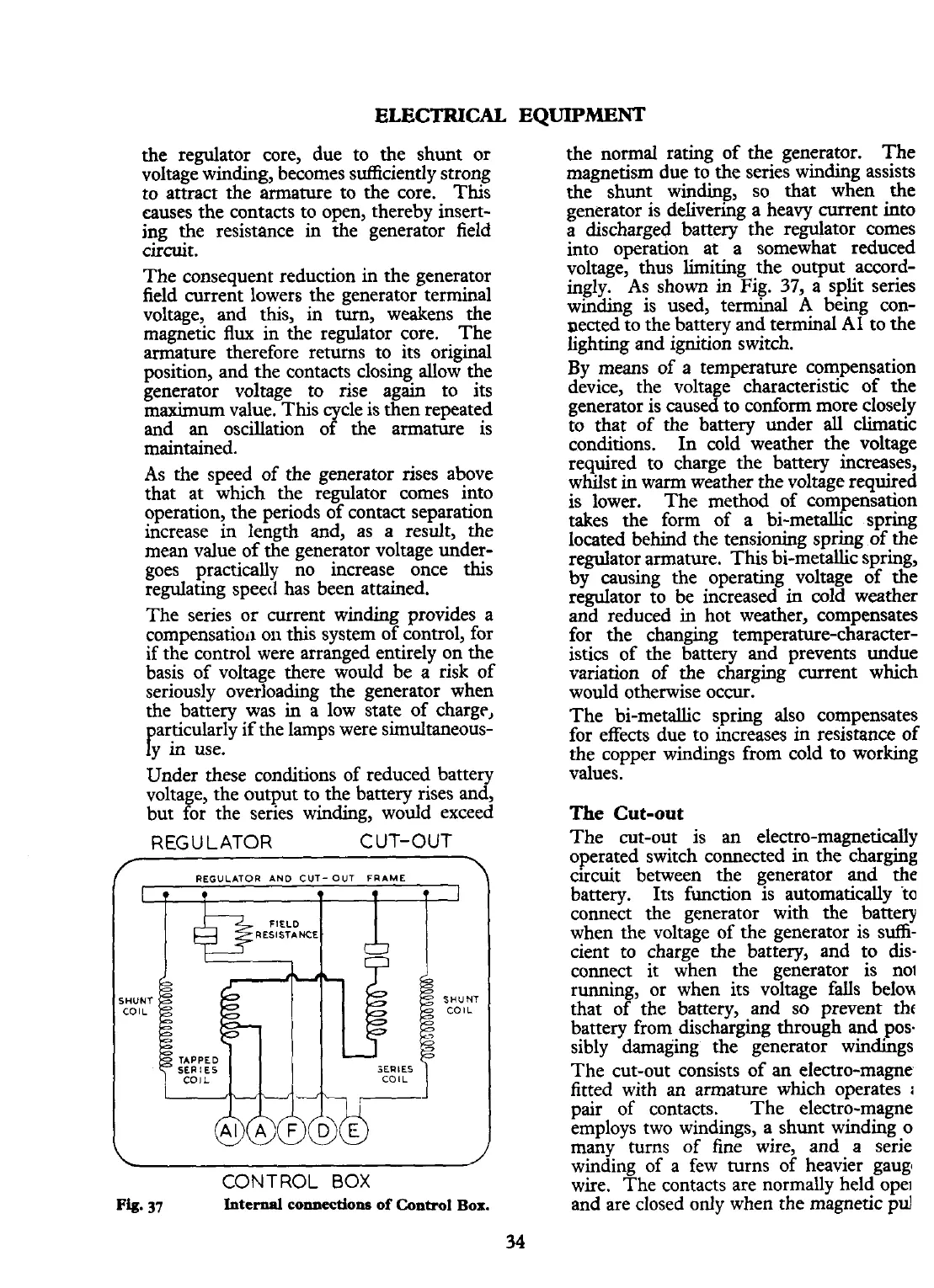

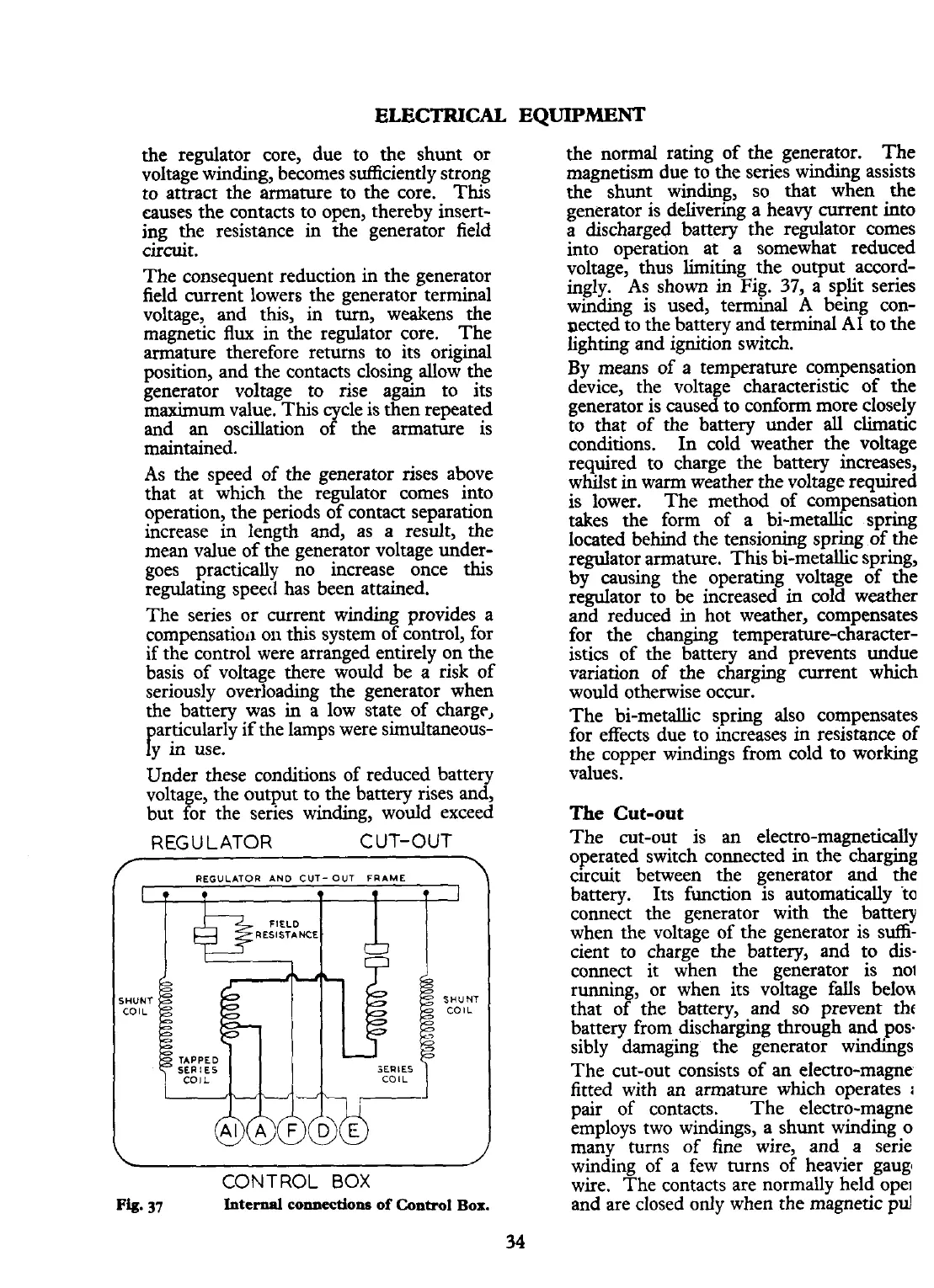

Under these conditions of reduced battery

voltage, the output to the battery rises and,

but for the series winding, would exceed

REGULATOR CUT-OUT

/

\

;HUNT

COIL

SHUNT

COIL

CONTROL BOX

Fk.

37

Internal

connections

of

Control

Box.

34

the normal rating of the generator.

The

magnetism due to the series winding assists

the shunt winding, so that when the

generator is delivering a heavy current into

a discharged battery the regulator comes

into operation at a somewhat reduced

voltage, thus limiting the output accord-

ingly. As shown in Fig.

37,

a split series

winding is used, terminal A being con-

~ected to the battery and terminal AI to the

lighting and ignition switch.

By means of a temperature compensation

device, the voltage characteristic of the

generator is caused to conform more closely

to that of the battery under

all

climatic

conditions. In cold weather the voltage

required to charge the battery increas&,

whilst in warm weather the voltage reauired

is lower.

The method of cohpensation

takes the form of a bi-metalhc spring

located behind the

tensioning spring of the

regulator armature. This bi-metallic spring,

by causing the operating voltage of the

regulator to be increased in cold weather

and reduced in hot weather, compensates

for the changing

temperature-character-

istics of the battery and prevents undue

variation of the charging current which

would otherwise occur.

The bi-metallic spring also compensates

for effects due to increases in resistance of

the copper windings from cold to working

values.

The

Cut-out

The cut-out is an electro-magnetically

operated switch connected in the charging

circuit between the generator and the

battery. Its function is automatically

ta

connect the generator with the battery

when the voltage of the generator is suffi-

cient to charge the battery, and to dis-

connect it when the generator is

no1

running, or when its voltage falls below

that of the battery, and so prevent tht

battery from discharging through and pos.

sibly damaging the generator windings

The cut-out consists of an electro-magm

fitted with an armature which operates

:

pair of contacts. The electro-magne

employs two windings, a shunt winding o

many turns of fine wire, and a serie

winding of a few turns of heavier

gaug

wire. The contacts are normally held opel

and are closed only when the magnetic pul

Loading...

Loading...