BODY

used, or a hot air blast can be directed to

the lacquer.

If neither oven nor hot air

blast is available the component can be

left undisturbed in

a

warm atmosphere

for

24

hours. Although reasonable sealing

will be obtained by the instructions con-

tained

in

this paragraph, the proper heat

treatment at the higher temperature will

provide the best possible water proofing.

ADJUSTMENT OF SIDE CURTAINS

An aluminium

wedge with two tapped

holes is attached to each side screen support

stay by a single screw which fits in slotted

apertures providing the adjustment.

It

is by moving these wedges up or down the

support stays that adjustment is obtained.

When adjustments have been completed

ensure that the press studs of the curtain

align with those on the door panel and the

support stays are secured in their sockets

by knurled screws.

32.

TO

PREPARE

CAR

FOR FIBRE-

GLASS

HARD

TOP CANOPY

(a)

Remove hood and fittings as described

on page

8.

(b)

Withdraw the screws securing the three

cappings to the rear elbow rail and

the fixing screw of the front petrol

tank

trim.

Protect the exterior of the

car

adjacent to the elbow rail with

masking tape.

(c)

Remove the millboard from the rear

of the petrol

tank

by withdrawing the

screws.

(d)

Assemble the windscreen bracket and

bridge pieces to the canopy.

(e)

Position canopy on the windscreen

and elbow rail of the car-windscreen

first.

Mark the position of the wind-

screen bracket holes on the flange.

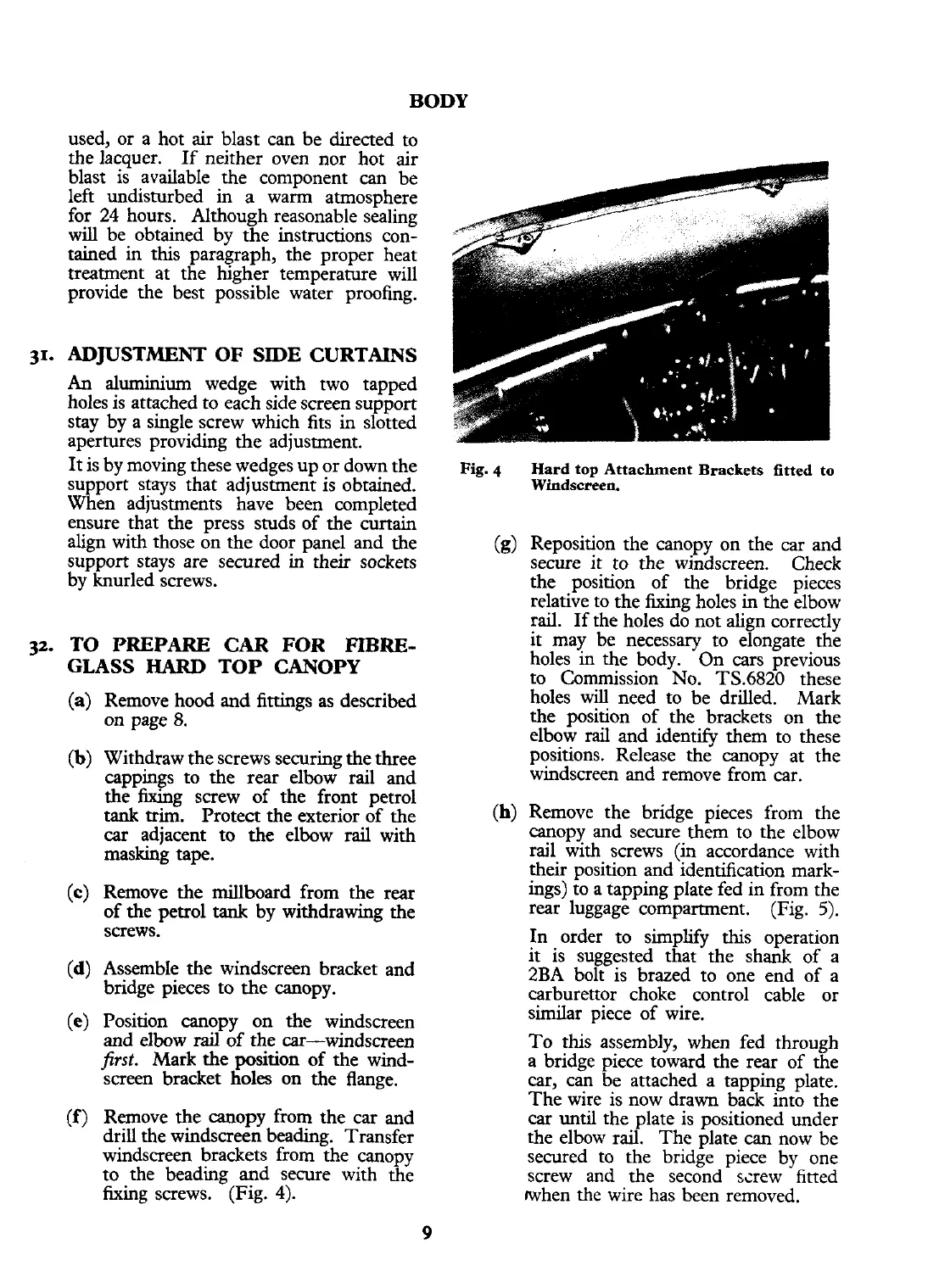

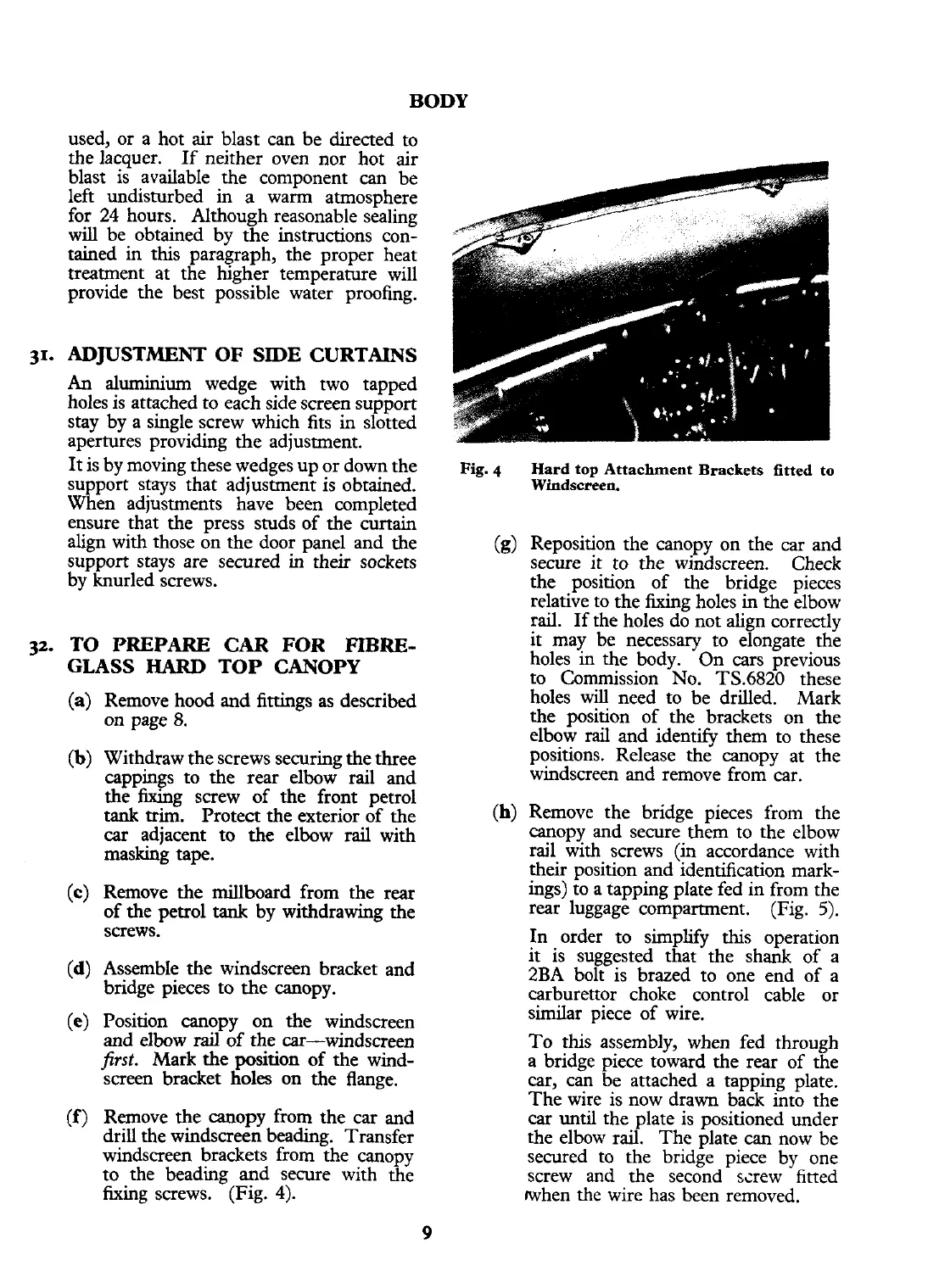

(f)

Remove the canopy from the car and

drill the windscreen beading. Transfer

windscreen brackets from the canopy

to the beading and secure with the

fixing screws. (Fig.

4).

Fig.

4

Hard top Attachment Brackets fitted to

Windscreen.

(g)

Reposition the canopy on the car and

secure it to the windscreen.

Check

the position of the bridge pieces

relative to the fixing holes in the elbow

rail. If the holes do not align correctly

it may be necessary to elongate the

holes in the body. On cars previous

to Commission No. TS.6820 these

holes will need to be drilled. Mark

the position of the brackets on the

elbow rail and

identlfy them to these

positions. Release the canopy at the

windscreen and remove from car.

(h)

Remove the bridge pieces from the

canopy and secure them to the elbow

rail with screws (in accordance with

their position and identification mark-

ings) to a tapping plate fed in from the

rear luggage compartment. (Fig.

5).

In order to simplify this operation

it is suggested that the shank of a

2BA bolt is brazed to one end of a

carburettor choke control cable or

similar piece of wire.

To this assembly, when fed through

a bridge piece toward the rear of the

car, can be attached a tapping plate.

The wire is now drawn back into the

car

until

the plate is positioned under

the elbow rail. The plate can now be

secured to the bridge piece by one

screw and the second screw fitted

when the wire has been removed.

Loading...

Loading...