FUEL

SYSTEM

3.

TO FIT PETROL

TANK

After ensuring that the tank is perfectly

sound and clean, it

can

be replaced in the

car.

The recommended method of testing the

tank is to clean the exterior with a wire

brush, blank off the filler pipe and

all

but

one union then connect to a compressed

air

line. Submerge the tank in water and

slowly

fill

the tank with

air.

Faults will

clearly be seen by escaping

air.

The replacement of the tank is the reversal

of the removal.

It

is a wise precaution to run the engine

for a short time to observe the connections

for leaks before replacing the

trim.

4.

PETROL GAUGE

Description

The petrol gauge comprises two com-

ponents, the dashboard meter and the tank

unit.

The dashboard meter consists of a metal

case, containing the coils and shaped knob

pieces which operate the gauge, also a

bezel with a calibrated dial and indicator

needle.

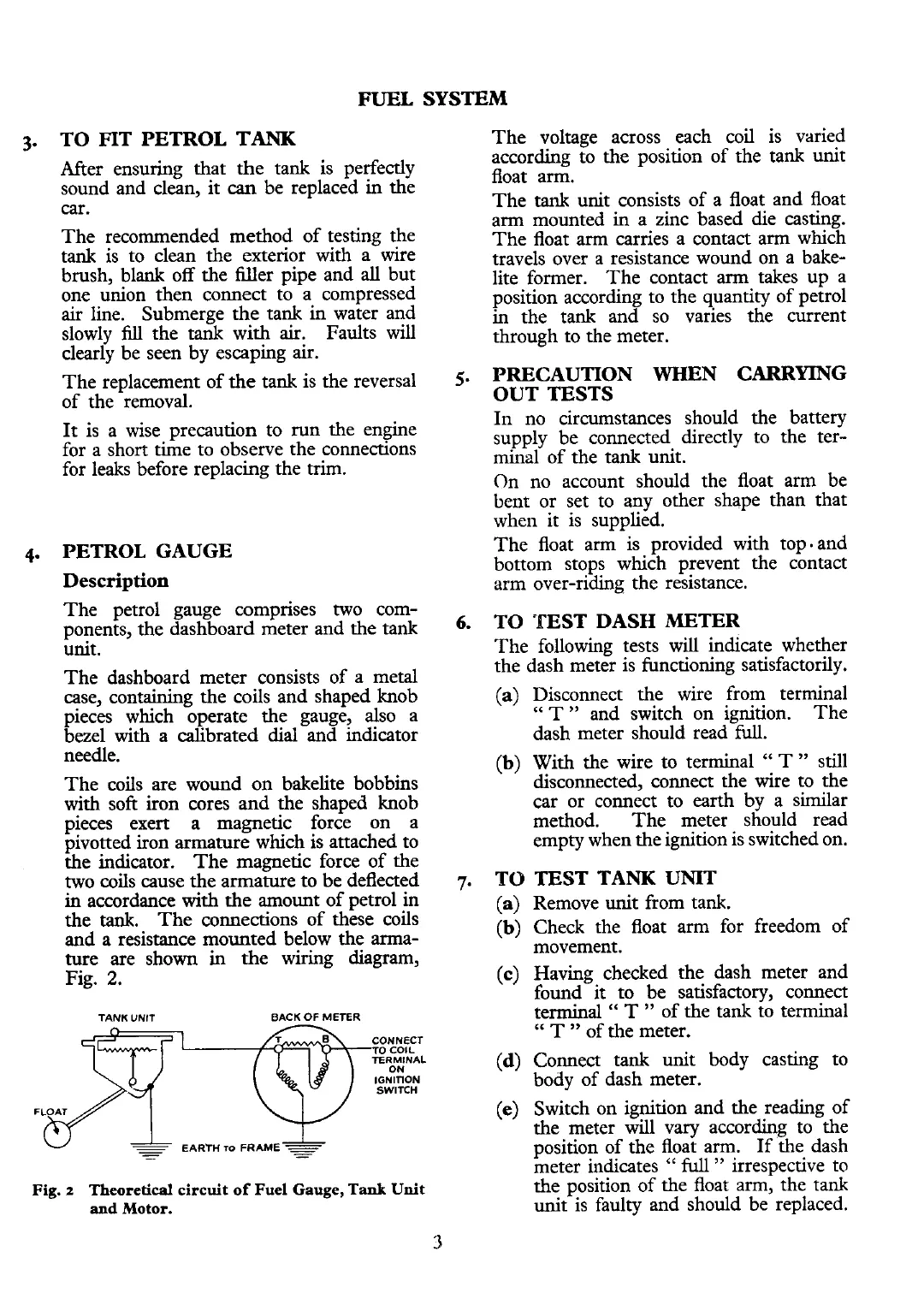

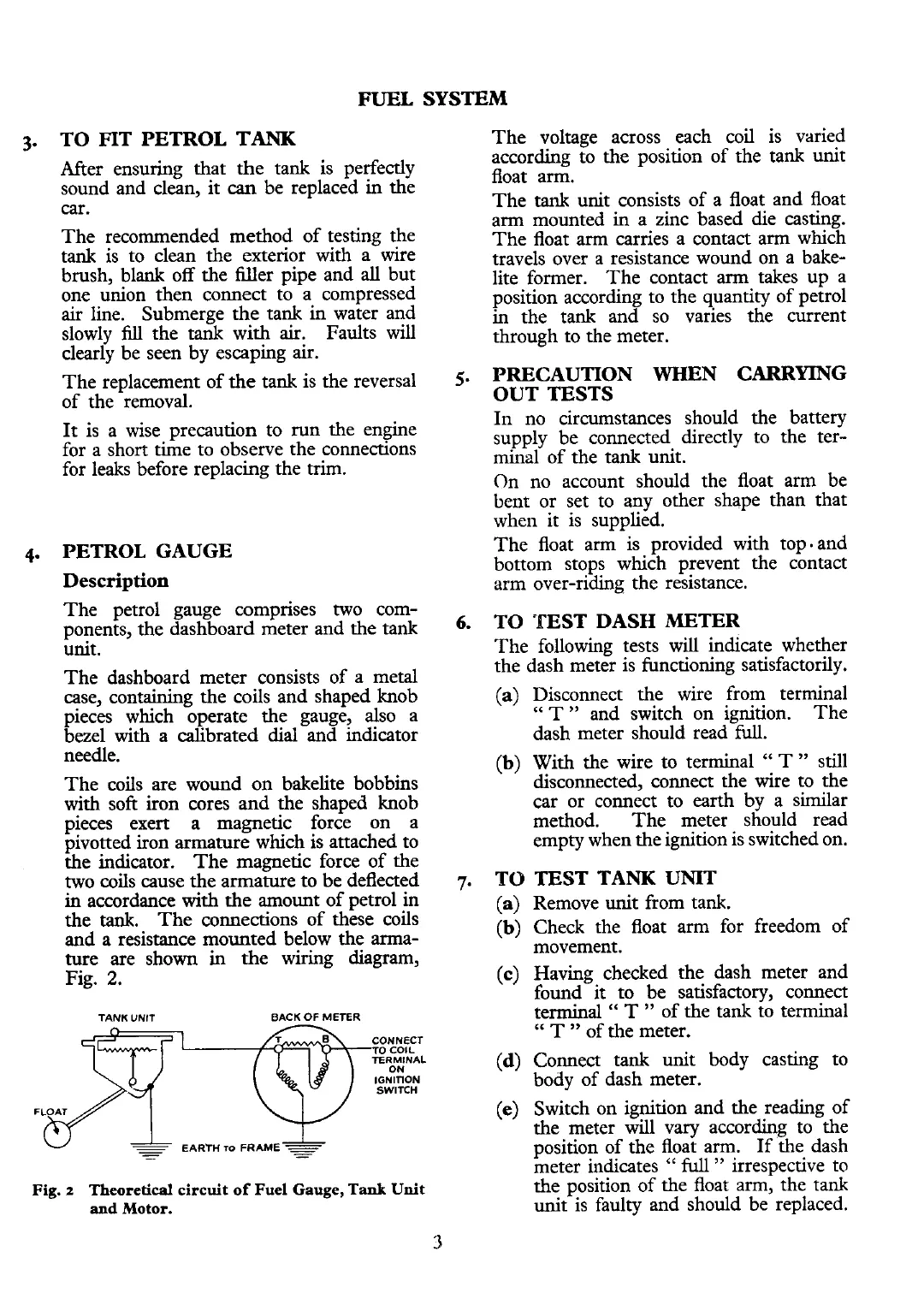

The coils are wound on

bakelite bobbins

with soft iron cores and the shaped knob

pieces exert a magnetic force on a

pivotted iron armature which is attached to

the indicator. The magnetic force of the

two coils cause the armature to be deflected

The voltage across each coil is varied

according to the position of the tank unit

float arm.

The tank unit consists of a float and float

arm mounted in a zinc based die casting.

The float arm carries a contact arm which

travels over a resistance wound on a

bake-

lite former. The contact arm takes up a

position according to the quantity of petrol

in the tank and so varies the current

through to the meter.

in

accordance with the amount of petrol in

the

tank.

The connections of these coils

and

a

resistance mounted below the arma-

ture are shown

in

the wiring

diagram,

Fig.

2.

TANK UNIT BACK

OF

METER

CONNECT

TO COIL

TERMINAL

ON

IGNITION

SWITCH

Fig.

2

Theoretical

circuit

of

Fuel Gauge,

Tank

Unit

and

Motor.

5.

PRECAUTION WHEN CARRYING

OUT TESTS

In no circumstances should the battery

supply be connected directly to the ter-

minal of the tank unit.

On no account should the float arm be

bent or set to any other shape than that

when it is supplied.

The float arm is provided with top- and

bottom stops which prevent the contact

arm over-riding the resistance.

6.

TO

TEST DASH METER

The following tests will indicate whether

the dash meter is functioning satisfactorily.

(a)

Disconnect the wire from terminal

"

T

"

and switch on ignition.

The

dash meter should read

full.

(b)

With the wire to terminal

"

T

"

still

disconnected, connect the wire to the

car or connect to earth by a similar

method. The meter should read

empty when the ignition is switched on.

7.

TO

TEST TANK UNIT

(a)

Remove unit from tank.

(b)

Check the float arm for freedom of

movement.

(c)

Having checked the dash meter and

found it to be satisfactory, connect

terminal

"

T

"

of the tank to terminal

"

T

"

of the meter.

(d)

Connect tank unit body casting to

body of dash meter.

(e)

Switch on ignition and the reading of

the meter will vary according to the

position of the float arm. If the dash

meter indicates

"

full

"

irrespective to

the position of the float arm, the tank

unit is faulty and should be replaced.

Loading...

Loading...