BRAKES

(h)

Position the cover plate on the body

in such a manner that the filler cap

is nearer the outlet ports. This

will

ensure the jets of fluid from the

cylinder will impinge upon the plate

and so avoid possible leakage through

the filler cap. Ensure that the joint

washer and filler cap sealing ring are

in good order and that the vent hole

is clear.

(i)

Test the assembly by filling the tank

with Lockheed Hydraulic Brake Fluid

to within 1" of the filler orifice top.

Then push the piston inward and it

should return without any assistance

;

after a few aplications fluid should be

ejected from the outlet connections.

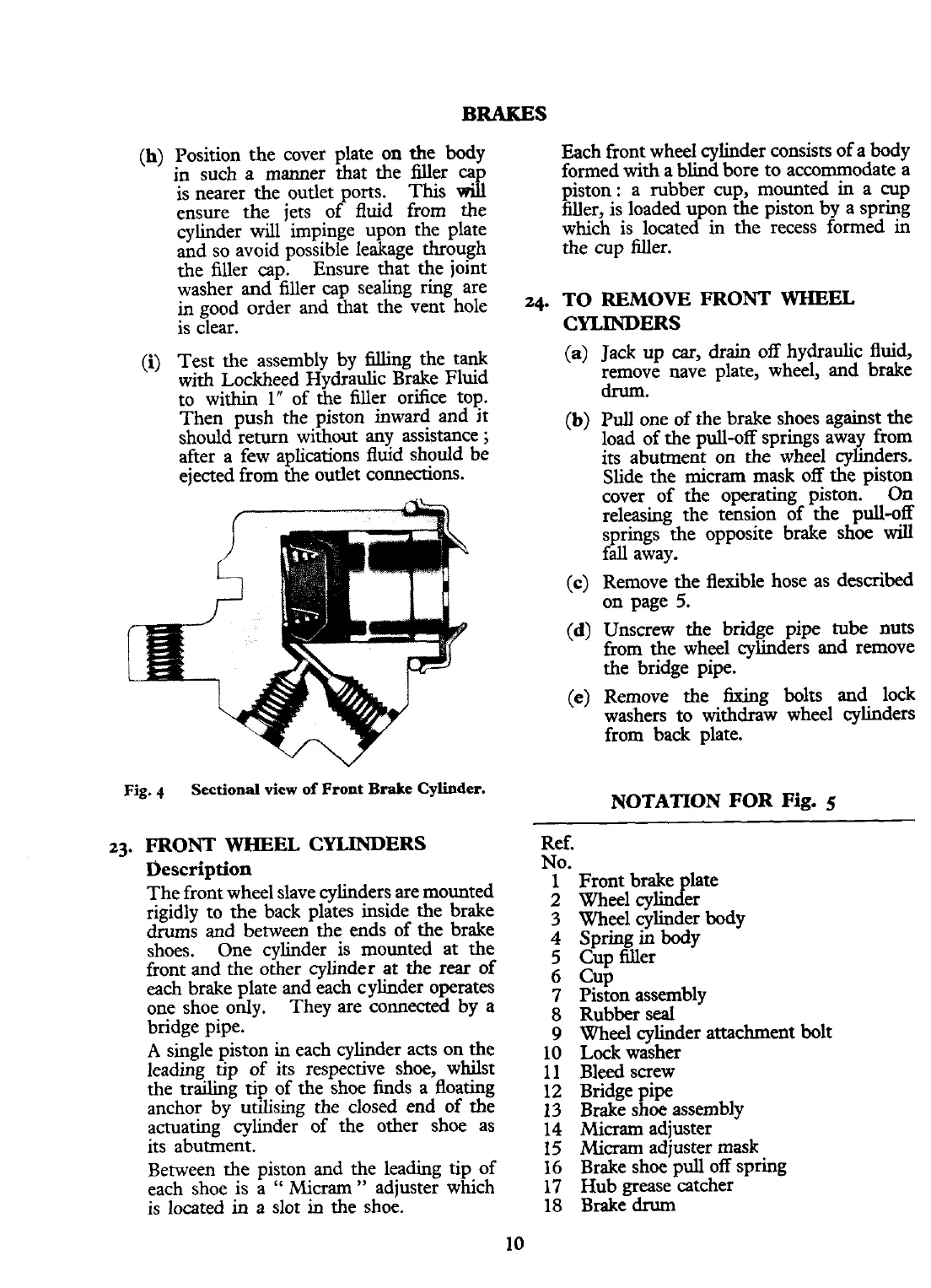

Fig.

q

Sectional

view

of

Front

Brake

Cylinder.

FRONT

WHEEL

CYLINDERS

Description

The front wheel slave cylinders are mounted

rigidly to the back plates inside the brake

drums and between the ends of the brake

shoes. One cylinder is mounted at the

front and the other cylinder at the

rear

of

each brake plate and each cylinder operates

one shoe only. They are connected by a

bridge pipe.

A

single piston

in

each cylinder acts on the

leading tip of its respective shoe, whilst

the trailing tip of the shoe finds a floating

anchor by utilising the closed end of the

actuating cylinder of the other shoe as

its abutment.

Between the piston and the leading tip of

each shoe is a

"

Micrarn" adjuster which

is located

in

a slot in the shoe.

Each front wheel cylinder consists of a body

formed with a blind bore to accommodate a

piston

:

a rubber cup, mounted in a cup

filler, is loaded upon the piston by a spring

which is located in the recess formed in

the cup filler.

24.

TO REMOVE FRONT

WHEEL

CYLINDERS

(a)

Jack up

car,

drain off hydraulic fluid,

remove nave plate, wheel, and brake

drum.

(b)

Pull one of the brake shoes against the

load of the pull-off springs away from

its abutment on the wheel cylinders.

Slide the

micram mask off the piston

cover of the operating piston. On

releasing the tension of the pull-off

springs the opposite brake shoe

wiU

fall away.

(c)

Remove the flexible hose as described

on page 5.

(d)

Unscrew the bridge pipe tube nuts

from the wheel cylinders and remove

the bridge pipe.

(e)

Remove the fixing bolts and lock

washers to withdraw wheel cylinders

from back plate.

NOTATION

FOR Fig.

5

Ref.

No.

1 Front brake late

c!

2

Wheel cylin er

3 Wheel cylinder body

4

Spring in body

5

Cup filler

6

Cup

7

Piston assembly

8 Rubber seal

9

Wheel cylinder attachment bolt

10 Lock washer

11 Bleed screw

12 Bridge pipe

13 Brake shoe assembly

14

Micrarn

adjuster

15

Micram

adjuster mask

16 Brake shoe pull off spring

17

Hub grease catcher

18 Brake

drum

Loading...

Loading...