REAR

AXLE

I.

GENERAL

A

new rear axle assembly, Part No. 302177,

bearing the Serial No. 13511, was jntro-

duced at Commission No. 13046 and fitted

on all subsequent cars.

The major differences incorporated in the

new axle include new half shaft and hub

assemblies, a thrust button mounted on the

differential cross-pin and adjustable taper

roller hub bearings, as shown in Fig. 1.

The sectioned insert views indicate the axle

arrangement for cars prior to this change.

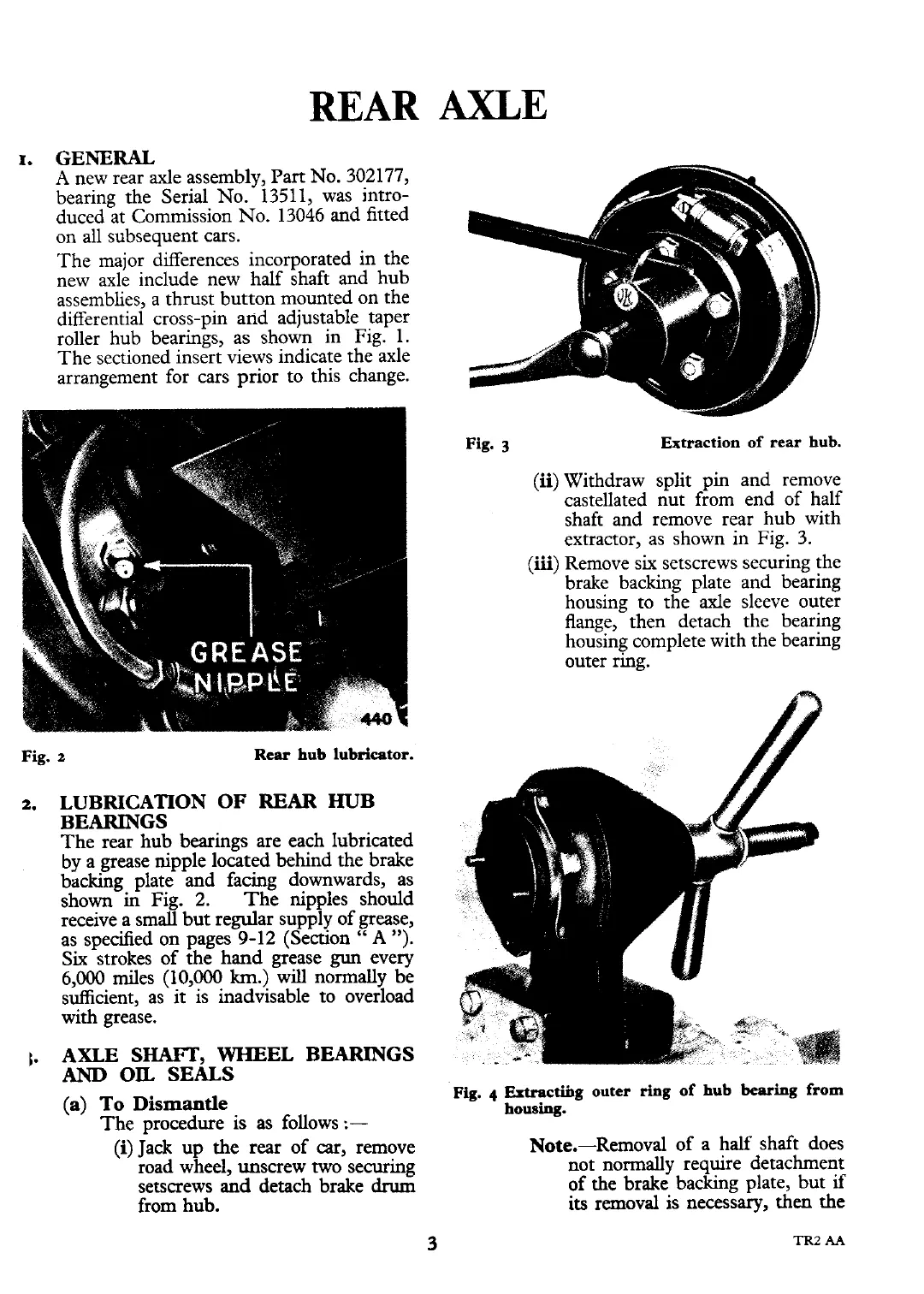

Fig.

3

Extraction of rear hub.

(ii) Withdraw split pin and remove

castellated nut from end of half

shaft and remove rear hub with

extractor, as shown in Fig.

3.

(iii)

Remove six setscrews securing the

brake backing plate and bearing

housing to the axle sleeve outer

flange, then detach the bearing

housing complete with the bearing

outer ring.

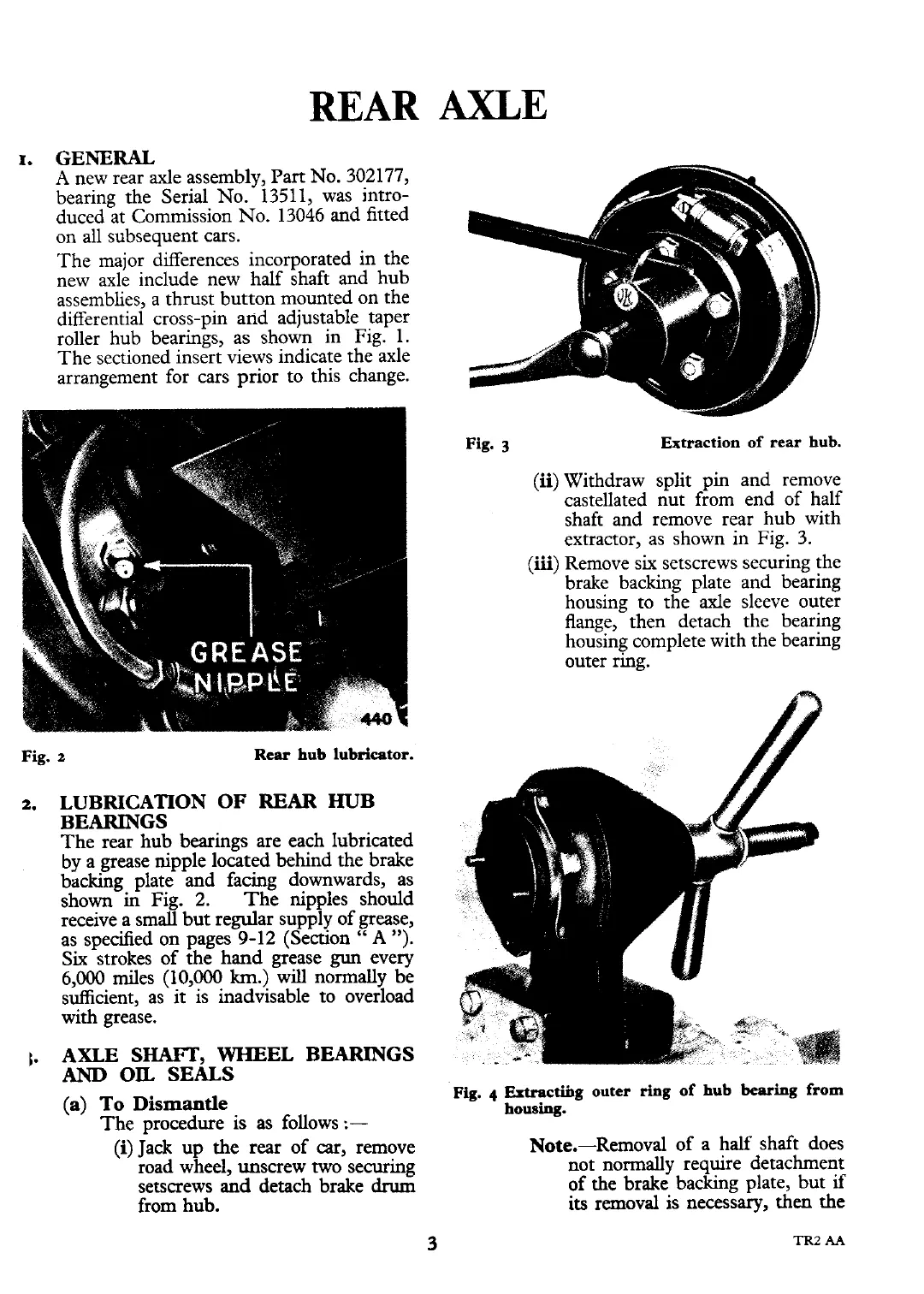

Fig.

t

Rear

hub lubricator.

2.

LUBRICATION OF

REAR

HUB

BEARINGS

The rear hub bearings are each lubricated

by a grease nipple located behind the brake

backing plate and facing downwards, as

shown in Fig. 2. The nipples should

receive a small but regular supply of grease,

as specified on pages

9-12

(Section

"

A

").

Six strokes of the hand grease

gun

every

6,000 miles (10,000

km.)

will normally be

sufficient, as it is inadvisable to overload

with grease.

1.

AXLE SHAFT,

WHEEL

BEARINGS

AND

OIL

SEALS

(a)

To

Dismantle

The procedure

is

as follows

:-

(i) Jack up the

rear

of

car,

remove

road wheel, unscrew

two

securing

setscrews

and

detach brake

drum

from hub.

Fig.

4

Extractii~g

outer

ring

of hub

bearing

from

housing.

Note.-Removal of a half shaft does

not normally require detachment

of the brake backing plate, but

if

its

removal is necessary, then the

Loading...

Loading...