REAR

AXLE

hub, plain washer and castellated

nut, tightening this to a torque

of 125-145 lbs. ft. (17.29-19.71 kg.

metres) and securing it with a

split pin.

(iv) Examine the inner oil seal and,

if a replacement is necessary,

proceed as shown in Fig.

8.

Oil

seal renewal is recommended in

all cases of axle overhaul.

(v) Replace the original shim pack

over the spigoted portion of the

axle sleeve, followed by the brake

backing plate.

(vi) Again exercising care in the case

of the inner oil seal, thread the

assembled axle shaft through the

seal and into the axle casing. After

locating the shaft splines in those

of the sun wheel, secure the

bearing housing by inserting arid

tightening six setscrews with

lock-

plates.

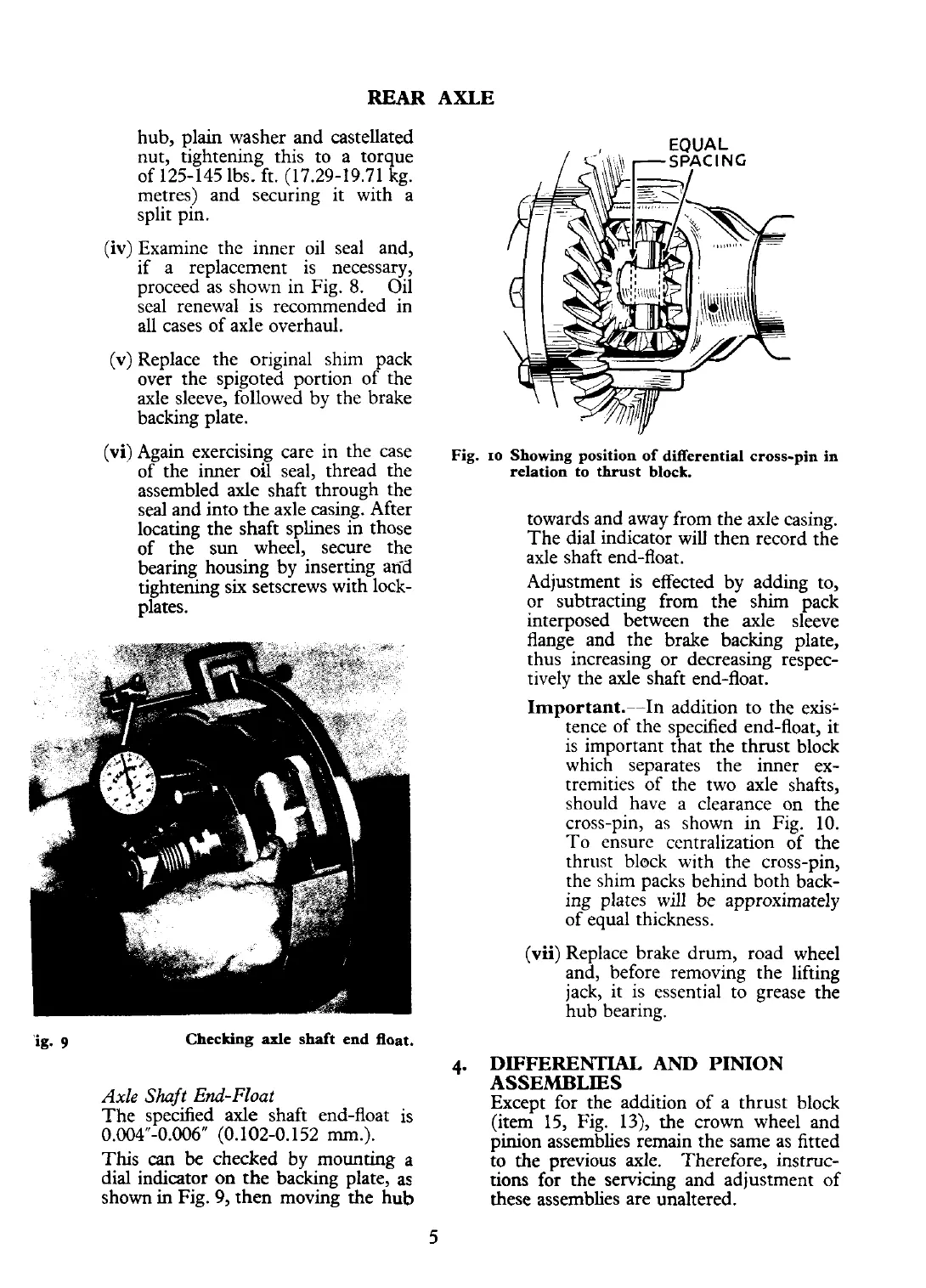

'ig.

9

Checking axle shaft end float.

Axle

Shaft

End-Float

The specified axle shaft end-float is

0.004"-0.006'' (0.102-0.152

mm.).

This

can

be

checked by mounting a

dial indicator on the backing plate, as

shown in Fig.

9,

then moving the hub

EOUAL

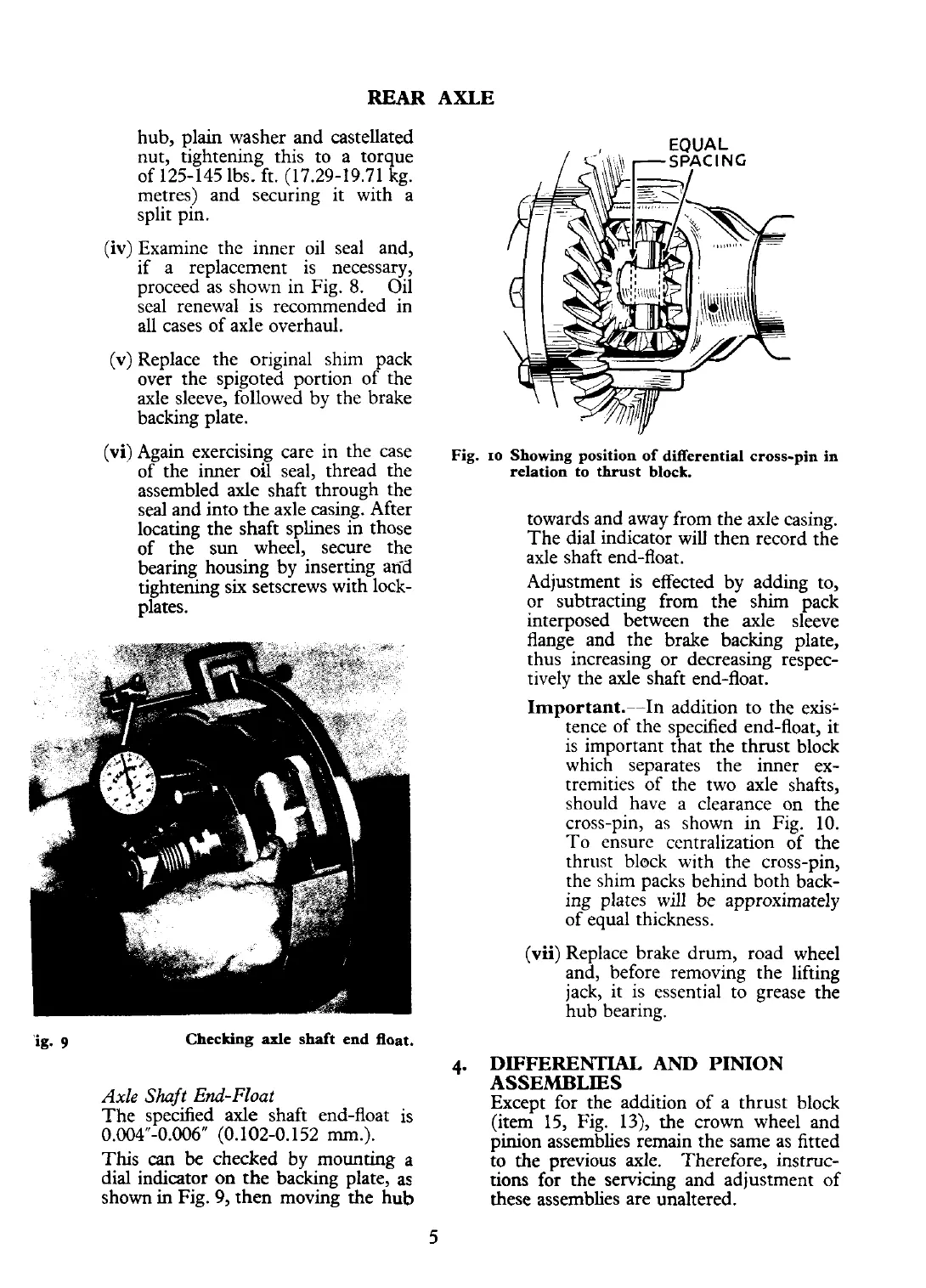

Fig.

10

Showing position of differential cross-pin in

relation to thrust

block.

towards and away from the axle casing.

The dial indicator will then record the

axle shaft end-float.

Adjustment is effected by adding to,

or subtracting from the shim pack

interposed between the axle sleeve

flange and the brake

backing plate,

thus increasing or decreasing respec-

tively the axle shaft end-float.

Important.--In addition to the exis-

tence of the specified end-float, it

is important that the thrust block

which separates the inner ex-

tremities of the two axle shafts,

should have a clearance on the

cross-pin, as shown in Fig. 10.

To ensure centralization of the

thrust block with the cross-pin,

the shim packs behind both back-

ing plates will be approximately

of equal thickness.

(vii) Replace brake drum, road wheel

and, before removing the lifting

jack, it is essential to grease the

hub bearing.

4.

DIFFERENTIAL

AND

PINION

ASSEMBLIES

Except for the addition of a thrust block

(item 15, Fig. 13), the crown wheel and

pinion assemblies remain the same as fitted

to the previous axle. Therefore, instruc-

tions for the servicing and adjustment of

these assemblies are unaltered.

Loading...

Loading...