BRAKES

Instead of pushing the pistons to the

bottom of the bore withdraw them

from the caliper body, taking great

care not to damage the bores. The

sealing rings may then be removed by

inserting a blunt tool under the seals

and prising out, taking care not to

damage the locating grooves.

Ex-

amine the bores and pistons carefully

for any signs of abrasion or "scuffing."

No attempt should be made to remove

the end plug retainer, as this is screwed

in tightly by mechanical means.

It is important that in cleaning the

components no petrol, paraffin,

tri-

chlorethylene or mineral

fluid

of any

kind

should be used. Clean with

methylated spirits and allow to vapor-

ise, leaving the component clean and

dry.

After cleaning and examining, lubricate

the working surfaces of the bores .md

piston with clean genuine

Gi.

g

Crimson Brake and Clutch Fluid.

Assembling

Fit new rubber seals into the grooves

of caliper cylinder bore. Locate the

rubber dust cover with the projecting

lip into the groove provided which is

the outer one of the cylinder bore.

Insert the piston, closed end first, into

%-

3

Rear

Drum

Brake Assembly.

the bore, taking great care not to

damage the polished surface. Push the

piston right home and then engage the

outer lip of the rubber boot into the

groove of piston.

The replacement of the lining segments

as described under the heading

"

Seg-

ment Replacement

"

will

retain the

pistons in position.

Refit the caliper assembly to the sup-

port bracket by means of the two

securing bolts ensuring that the disc

passes between the two lining segments.

Re-connect the pressure

hose and bleed

the brake, as described under

"

Bleed-

ing the System."

2.

DISCS

To ensure that the brake functions at

maximum efficiency a check should be

made to see that the disc runs truly

between the segments. The maximum

run-out permissible on the disc is

.004".

(For instructions regarding wheel bearing

settings refer to page

7,

Section

"

G," in

the main part of this manual.) If excessive

run-out is present this will cause the

knocking back of the pistons which will

possibly cause judder.

If it is found that the discs have been

damaged in any way, which is extremely

unlikely, it will be necessary to remove the

discs from the car in order for them to be

"

trued

"

up. Under no circumstances

should more than

.060fr

be removed, with

the finish to be

32

micro ins.

maximum

measured circumferentially and

50

micro

ins. measured radially.

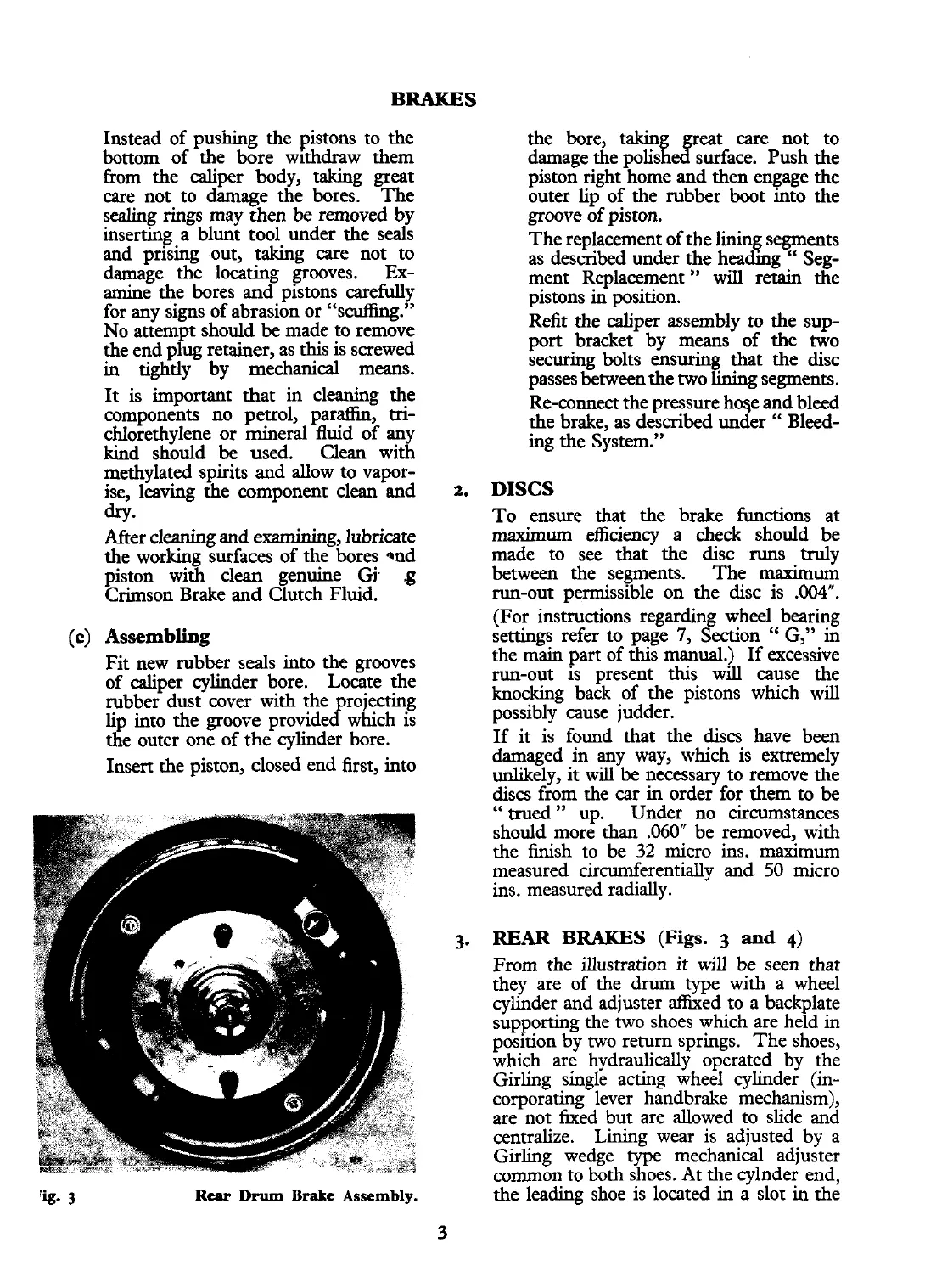

3.

REAR BRAKES

(Figs.

3

and

4)

From the illustration it will

be

seen that

they are of the drum type with a wheel

cylinder and adjuster &ed to a backplate

supporting the two shoes which are held in

position by two return springs. The shoes,

which are hydraulically operated by the

Girling single acting wheel cylinder (in-

corporating lever handbrake mechanism),

are not fixed but are allowed to slide and

centralize. Lining wear is adjusted by a

Girling wedge type mechanical adjuster

common to both shoes. At the cylnder end,

the leading shoe is located in a slot in the

Loading...

Loading...