ENGINE

Fig.

15

EXploded view of Distributor and Tacho-

meter Drive Details.

The main bearings are of the precision

type, bi-metal steel backed. No hand

fittlng is required and in no circumstances

should the bearing caps be fled with a

view to taking up wear. The Ning of

bearing caps will make them unserviceable

for future use when new bearings are

ultimately used.

WJhere excessive bearing wear has occurred

the only satisfactory cure is to replace worn

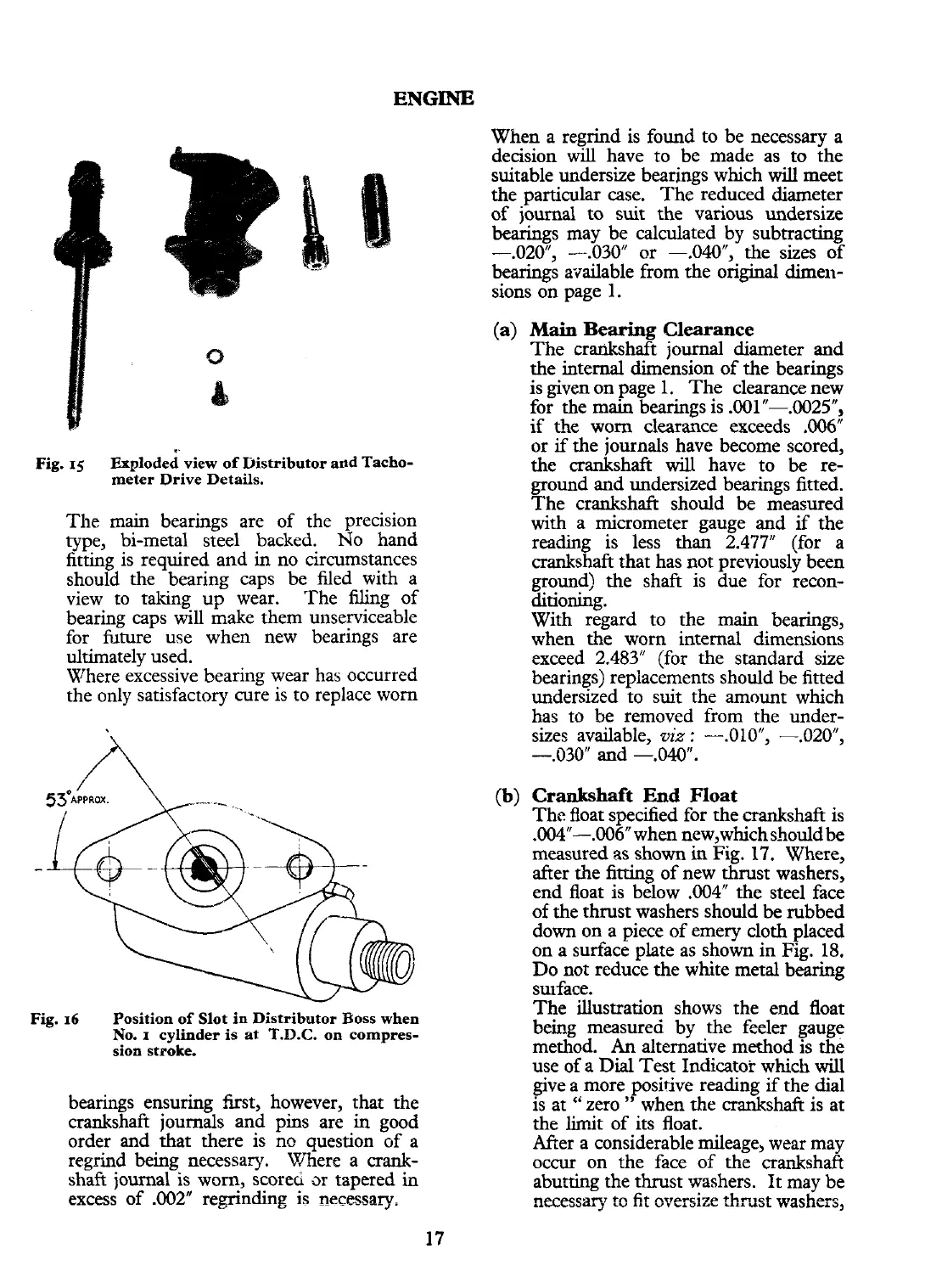

Fig.

16

Position of Slot in Distributor Boss when

No.

I

cylinder

is

at

T.D.C.

on compres-

sion stroke.

bearings ensuring first, however, that the

crankshaft journals and pins are

in

good

order and that there is

no

question of a

regrind being necessary. Where a crank-

shaft journal is worn, scoreci

or

tapered in

excess of .002" regrinding

is

necessary;

When a regrind is found to be necessary a

decision

will

have to be made as to the

suitable undersize bearings which

will

meet

the particular case. The reduced diameter

of journal to suit the various undersize

bearings may be calculated by subtracting

-.020, -.030" or -.04OU, the sizes of

bearings available from the ori@ dimen-

sions on page 1.

(a)

Main

Bearing

Clearance

The crankshaft journal diameter and

the internal dimension of the bearings

is given on page

l.

The clearance new

for the main bearings is .00lV-.002Sr',

if

the worn clearance exceeds

.006"

or

if

the journals have become scored,

the crankshaft

will

have to be re-

ground and undersized bearings fitted.

The crankshaft should be measured

with a micrometer gauge and if the

reading is less

than

2.477" (for a

crankshaft that has not previously been

ground) the shaft is due for recon-

ditioning.

With regard to the main bearings,

when the worn internal dimensions

exceed

2.483"

(for the standard size

bearings) replacements should be fitted

undersized to suit the amount which

has to be removed from the under-

sizes available,

viz

:

-.010", -.02OV,

-.030" and -.04OU.

(b)

Crankshaft

End

Float

The float specified for the crankshaft is

.004"-.006"

when ncw,whichshould be

measured

as

shown

in

Fig. 17. Where,

after the

fitting

of new thrust washers,

end float is below

304"

the steel face

of the thrust washers should

be

rubbed

down on a piece of emery cloth placed

on a surface plate as shown in Fig. 18.

Do not reduce the white metal bearing

sulface.

The illustration shows the end float

being measured by the feeler gauge

method.

An

alternative method

is

the

use of a

Dial

Test Indicator which

will

give a more positive reading if the dial

is at "zero

"

when the crankshaft is at

the limit of its float.

After a considerable mileage, wear may

occur on the face of the crankshaft

abutting the thrust washers. It may be

mcessary

to

fit

eversize

thmst

washers,

Loading...

Loading...