ELECTRICAL

EQUIPMENT

Inspection of Commutator

Disconnect the wiper at its terminals

and withdraw the three screws securing

the cover at the

commutator end.

Lift

off the cover. Clean the commutator,

using a petrol-moistened cloth, taking

care to remove any carbon dust from

between the commutator segments.

Inspection of

Brush

Gear

Check that the brushes bear freely on

the commutator. If they are loose or do

not make contact, a replacement ten-

sion spring is necessary. The brush

levers must be free on their pivots. If

they are stiff, they should be freed by

working them backwards and forwards.

Brushes which are considerably worn

must be replaced.

Motor Operates but does not

Transmit Motion to Spindles

-

Remove the gearbox cover.

A

push-

pull motion should be transmitted to

the inner cable of the flexible rack. If

the crosshead moves sluggishly be-

tween the guides, lightly smear a

small amount of medium grade engine

oil in the groove formed in the die-cast

housing.

When overhauling, the gearbox must

be lubricated by

packing it

with

a

grease of the zinc oxide base type.

2.

FLASHING LIGHT DIRECTION

INDICATORS

ELECTRIC

WINDTONE HORNS

-

Models

W614

and

W618

I.

GENERAL

Windtone horns de end for their operation

P.

on the vibration o

an

au

column, excited

at its resonant frequency, or a harmonic of

it, by an electrically energised diaphragm.

The horns are fitted in pairs, one horn

having a higher note than the other. The

horns differ in note by an interval of a

major third. Earlier fitment

WT614 and

later

WT618 horns are recognisable from

each other by the different shape of their

trumpet flares. High and low note horns

can

be distinguished by the letters

"

H

"

or

"

L

"

marked inside the trumpet flares.

(a)

Note of Horn Unsatisfactory or

Operation Intermittent

(i)

Check that the bolts securing the

horn bracket are tight and that the

body or flare of the horn does not

foul any other fixture. See that

any units fitted near the horn are

rigidly mounted, and do not vi-

brate when the horn is blown.

Examine the cables of the horn

circuit, renewing any that are

badly worn or chafed. Ensure

that all connections are tight, and

that the connecting eyelets or

nipples are firmly soldered to the

cables.

In the event of irregular operation of the

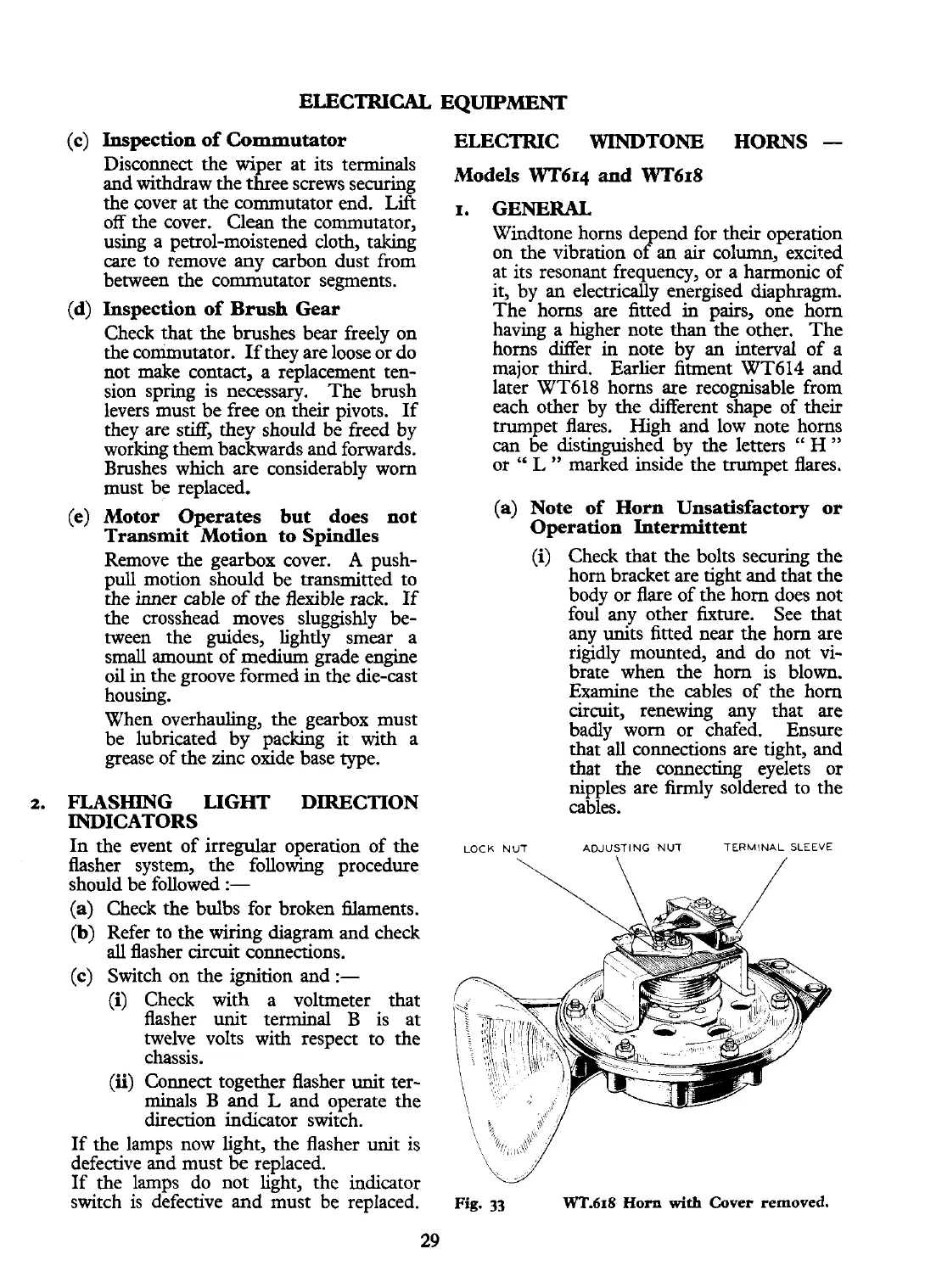

LOCK

NUT.

ADJUSTING

NUT

TERMINAL

SLEEVE

flasher system, the following procedure

should be followed

:-

(a)

Check the bulbs for broken filaments.

(b)

Refer to the wiring diagram and check

all

flasher circuit connections.

(c)

Switch on the ignition and

:-

(i)

Check with a voltmeter that

flasher unit terminal

B

is at

twelve volts with respect to the

chassis.

(ii)

Connect together flasher unit ter-

minals B and

L

and operate the

direction indicator switch.

If the lamps now light, the flasher unit is

defective and must

be

replaced.

If the lamps do not light, the indicator

switch is defective and must be replaced.

Fig.

33

wT.618

Horn

with

Cover removed.

Loading...

Loading...