12

Charging process

The APC310 has an electronic reverse battery protection.

The charging current is only released if the battery is cor-

rectly connected and there is a minimum voltage of 1.2V.

The charging process is carried out in accordance with the

charging reference line with a minimum of performance loss

(see “Charging reference line”). When a temperature sensor

is used, charging is carried out on a temperature-dependent

basis.

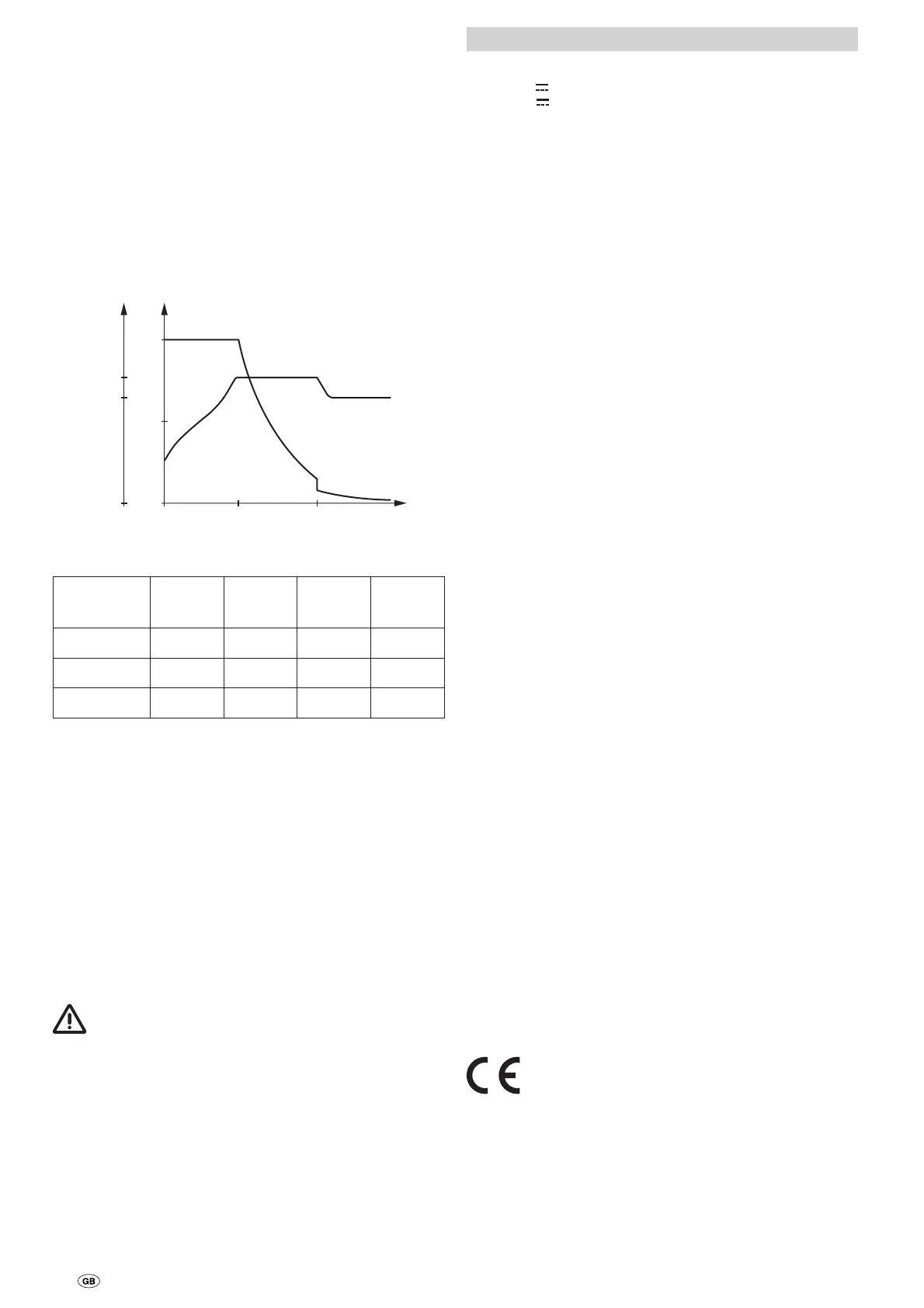

Charging reference line

HL = Main charging phase

NL = Afterloading phase

EL = Trickle charging

U

2

0

U[V]

U

1

0

50

100

I[%]

I

U

t[h]ELNLHL

Charging voltage (at 20°C)

Battery

type

HL – U

1

NL NL t[h] EL – U

2

Liquid 14,4V 14,4V 4 13,8V

Gel 14,4V 14,4V 10 13,8V

AGM 14,5V 14,5V 10 13,9V

Commissioning

The device is operational as soon as it is connected to the

APS400-K and the battery.

Removing the clamping space cover

Unlock the clamping space cover by pressing the two straps

at the same time and then remove (see page2, fig.A).

To attach the cover, push both straps into the slits of the hous-

ing shell and ensure that they click into place.

Maintenance

The power supply must always be completely discon-

nected before performing any maintenance work on the

device.

Clean the device and the ventilation slits with a dry and fluff-

free cloth.

Disposal

The device must be disposed of in line with the administra-

tive regulations of the respective country in which it is used.

National regulations and laws (in Germany, for example, the

End-of-life Vehicle Regulation) must be observed.

Technical data

Power supply

12V

via APS400-K

max. 22V

via solar

(System voltage: 12V,

idle voltage: panel max. 22V,

current: max. 10A,

corresponds to approx. 180Wp)

Output

Charging voltage (± 0.05V) – see “Charging reference line”

Arithmetic mean value, electronically controlled according to

the charging reference line IU

1

U

2

, sustained short-circuit pro-

tection, open-circuit protected

Nominal current

10A ± 0.5A at 35°C, above this, automatic power reduction

Residual ripple

<5%

Minimum battery voltage

1.2V

Charging process

Automatic

Temperature-dependent control (optional)

The values of the automatic switching device refer to a battery

temperature of 20 °C. If a temperature sensor is used with the

battery, these values will vary in accordance with the battery

temperature.

High temperature –> reduction of the threshold values.

Lower temperature –> higher threshold values.

Charging current lifter

max. 10A

Voltage lifter

14.5V

Monitoring under-voltage

OFF at 10.8V

ON at 12.5V

Use

To charge the batteries with 12V rated voltage and a capacity

of 50–150Ah.

Storage temperature

-20–+80°C

Housing temperature (in operation)

max. +80°C

Air humidity

5 – 95% without thawing

Noise

< 10dBA (at a distance of 1.5m)

Dimensions (L x W x H)

360 x 150 x 103mm

Weight

2.0kg

The right to effect technical modifications is reserved!

Loading...

Loading...