Wlof2

I

Part

7

-

Interface Setup

(cont.)

a

m-m

..

I.

-

-

.B

0.

A

AL4RMS

MORE

A

MORE

FRWORD

WAS

A

WAS

ENTER

DATA

GEN

CLK

ANALYSIS

MODE

Press the

A

(up-mow key) on the keypad

to

return to the

2M/Nx64

main menu.

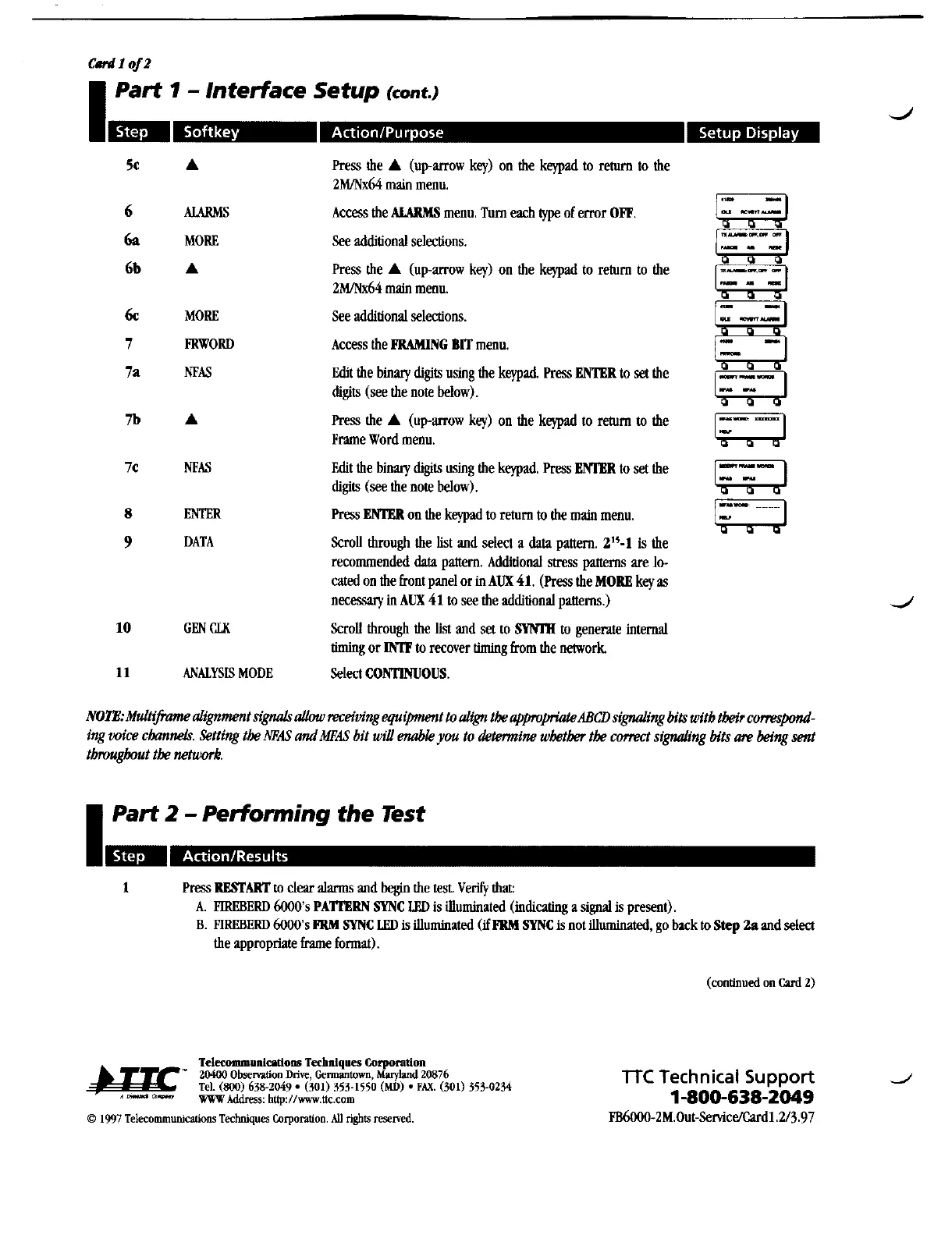

Access the

ALARMS

menu.

Turn

each

type

of em

OFF.

See

additional selections.

Press the

A

(up-mow key) on the keypad

to

return

to

the

2Wx64

main menu.

See additional selections.

Access the

FRAMING

BIT

menu.

Edit

the binary digits using the keypad.

Press

ENTER

to

set

the

digits (see the note below).

Press

the

A

(up-mow key) on the keypad

to

return

to

the

Frame Word menu.

Edit the binary digits using the keypad. Press

BNlgR

to set the

digits

(see

the note below).

Press

ENlUt

on the keypad to return to the main menu.

ScroU through the

list

and select a

data

panem.

2"-1

is

the

recommended

data

pattern. Additional

stress

patterns are lo-

cated on the front panel or in

AUX

41.

(Press

the

MOM

key

as

uecessaty

in

AUX

41

to

see

the additional patterns.)

ScmU through the list and set to

SWlX

to generate

internal

timing or

IWF

to

recover timing from the network

Select

CONTINUOUS.

NO~:Mult~

alignment

si&aUow

meiw'ng equipment to

a&

the

appmpriateABCD

signaling

bits

witb

tbeir

mspond-

ing voice

channels.

Setting the

NPAS

andMFAS

bit

will

enabk

you

to

determine whetber the mt signaling

bits

are

being sent

tbrougbout the netwk.

I

Part

2

-

Performing the Test

1

Press

ReSFART

to

clear

alarms

and

begin

the test. Verify that:

A.

HREBERD

6000's

PATl%RN

SYNC

LED

is illuminated (indicating a signal is present).

B.

FlREBERD

6000's

PRM

SYNC

Ln,

is illuminated

(if

FRM

SYNC

is not illuminated, go back to

Step

2a

and select

the appropriate frame format).

(continued on

Cud

2)

lTC

Technical

Support

J

1-800-638-2049

FB6000-2M.Out-S&cdCard1.2/3.97

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...