4 Model 334 Operations Manual

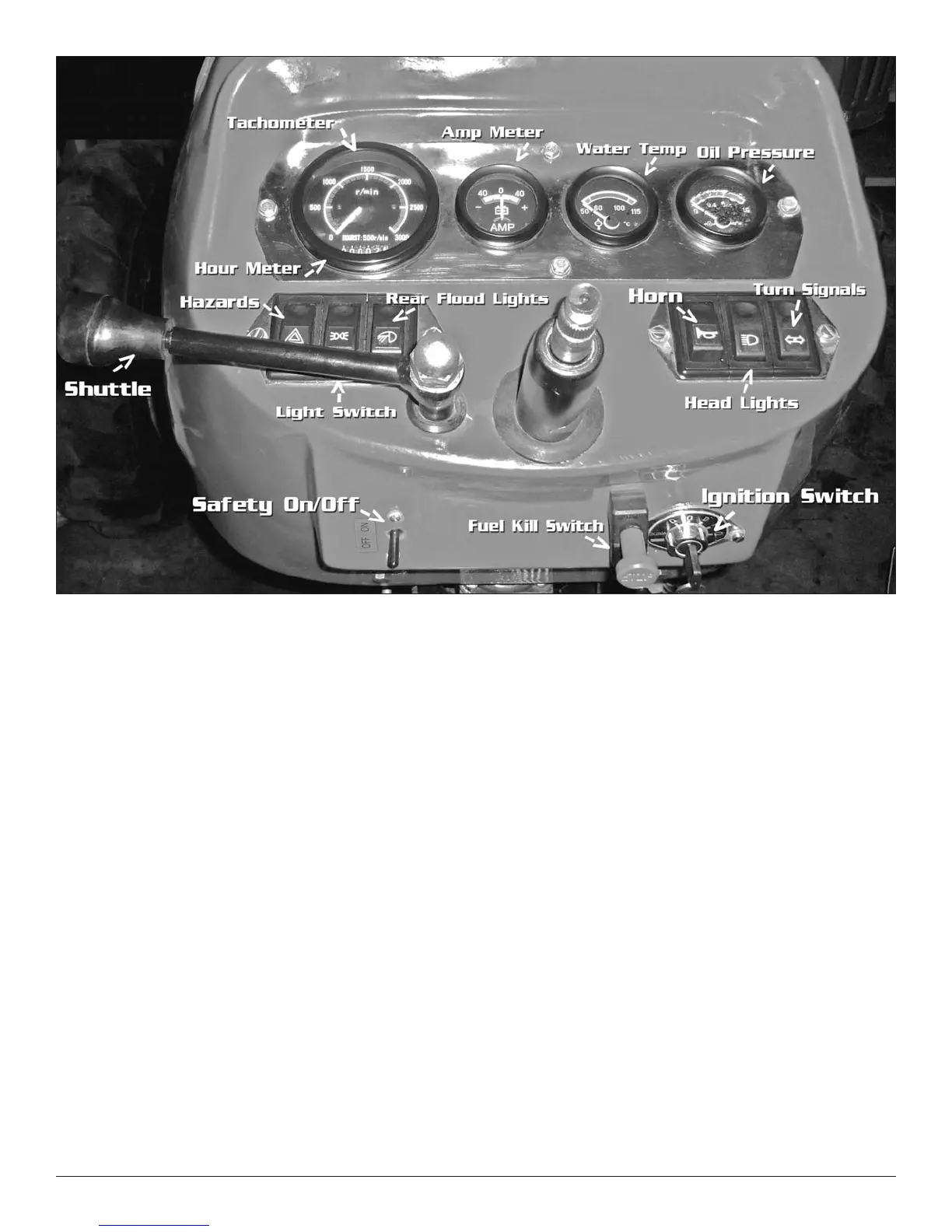

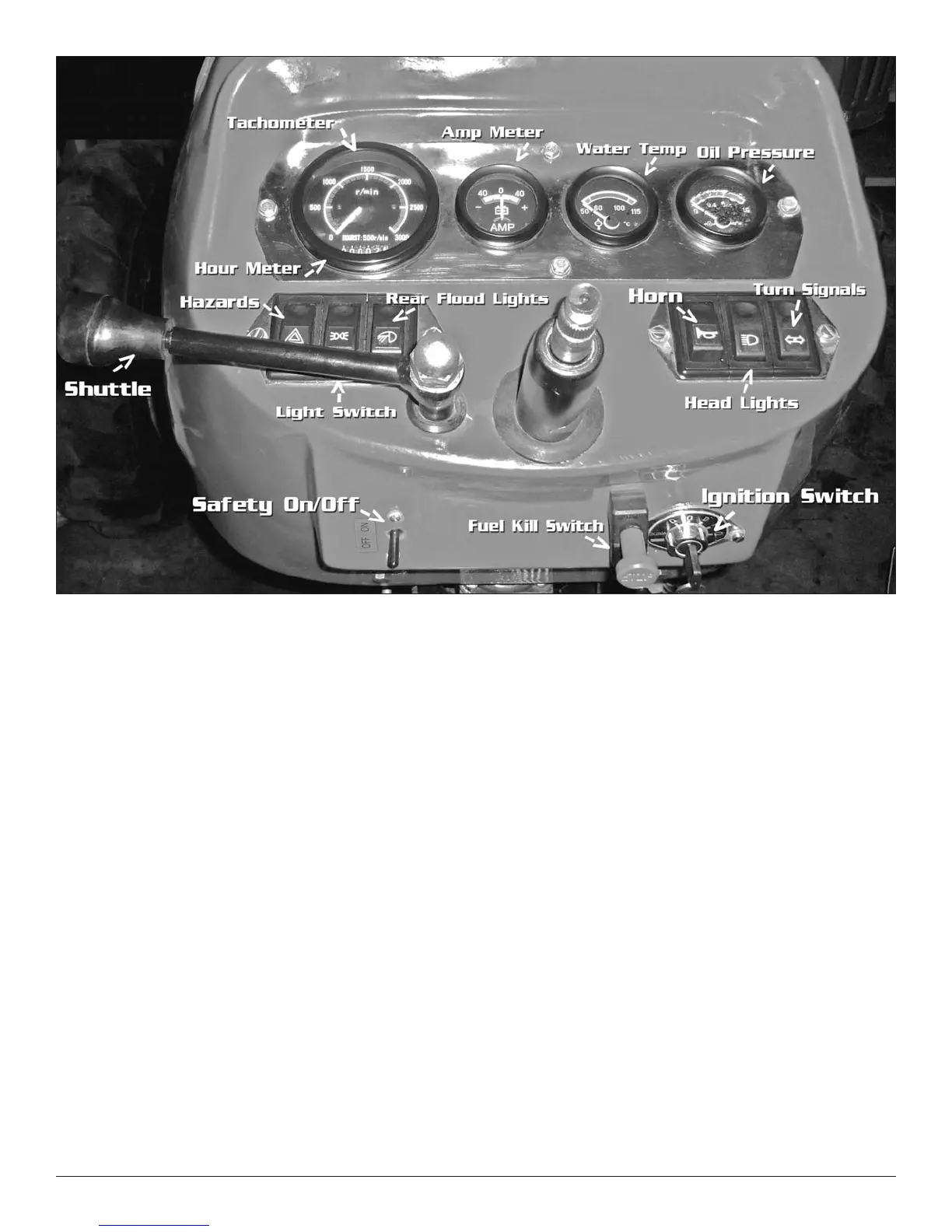

FIGURE 1: The basic layout of the main control panel.

released after starting it will spring back to the “run” position

while the tractor is running.

Shut off—Below the safety switch (see Fig. 1) and also below

the fiberglass lies the red knob that is a ‘pull type’ kill switch.

It is to be pulled out to kill the motor. Make sure it moves

freely back in when you release it.

Figure 2—

Shuttle Lever—Once you have selected the working gear range

that you prefer from the (on floor) gear shift lever and H/L

lever, you then can move the shuttle lever (on the left side of

the steering column) to forward, neutral or back positions for

tractor movement. This is a steering column type shuttle

shifter. Remember, that you cannot move the gears when

shuttle is engaged. Shuttle should be in neutral when select-

ing gears. This is a mechanical shuttle and requires using the

clutch to operate.

Two Stage clutch—this means when you depress the clutch to

the half way mark that will stop the ground speed of your

tractor. Pressing it further to the floor will stop the PTO. You

must depress the clutch pedal all the way to the floor in order

to have smooth engagement of the PTO lever. If there is any

noise or roughness in that engagement with the clutch all the

way to the floor, then that means there may need to be a

clutch adjustment made.

Brakes—there are twin brake pedals that have a flip-over pin

connecting them. They can be depressed individually for

steering but it isn’t recommended. To the left of the brake

pedals is a flip-up locking lever to use when parking the trac-

tor. Tractor brakes are not designed for heavy road use and

especially not for going down long hills. They will wear fast

if used in this manner.

Foot and Hand throttles—The foot throttle is handy to use at

various times however, in the field, using the hand throttle

gives you a constant RPM while in motion. The hand throttle

has an adjustment nut that can be tightened or loosened as

needed.

Gear shift lever—the gear pattern is seen just to the left of the

shifting lever. The key here is to fully engage into your gears

and to fully disengage. Otherwise if those gears are not

moved to the proper positions, it is possible to jam them. The

gears start out rather stiff when new but get much smoother

after 75 hours.

2WD-4WD lever—This lever is one you don’t want to move

accidentally when in operation. It is best to push the lever out

towards the fender just slightly before attempting to slide it

into position. Forward is 2WD and this is where you should

keep your tractor when you are off the farm land acreage. Pull

the lever back for 4WD.

Hydraulic and transmission oil fill—This has a dip stick and

that level should be ½" below the housing that the top plate

attaches to. We use Mobil #424, JD 303 or AW-46 oil for

this function. Sometimes it is labeled ‘tractor hydraulic oil’.

High & Low lever—this lever has low gear in the ‘down’ posi-

tion, neutral in the center and high in the ‘up’ position. The

normal user has no need to use high gear. The first gear low

is great for tilling and fourth low is great for bush hogging a

field of grass.

Locking Differential—this is an optional lever sold only as part

of a package purchase. This operates similar to positraction.

Loading...

Loading...