Model 334 Operations Manual 5

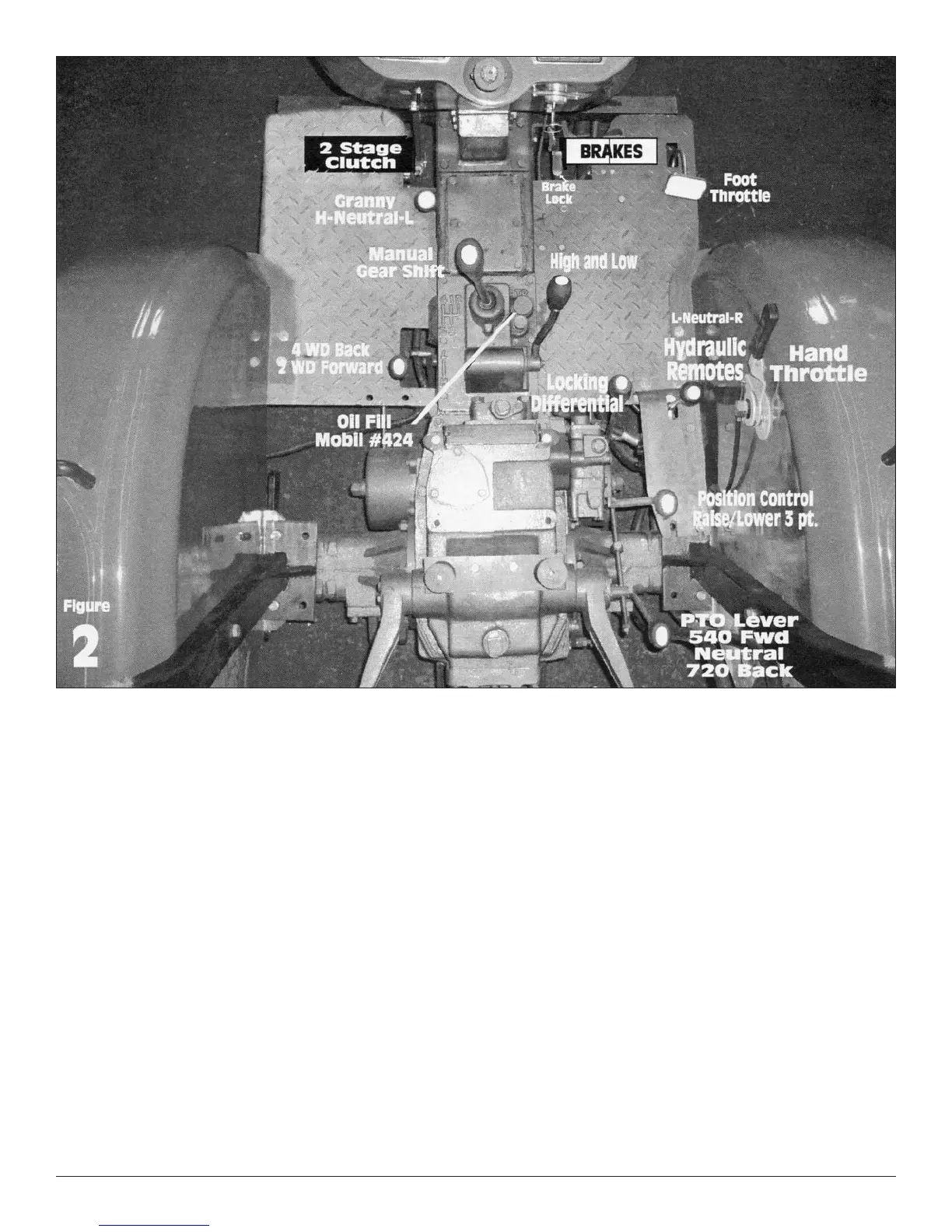

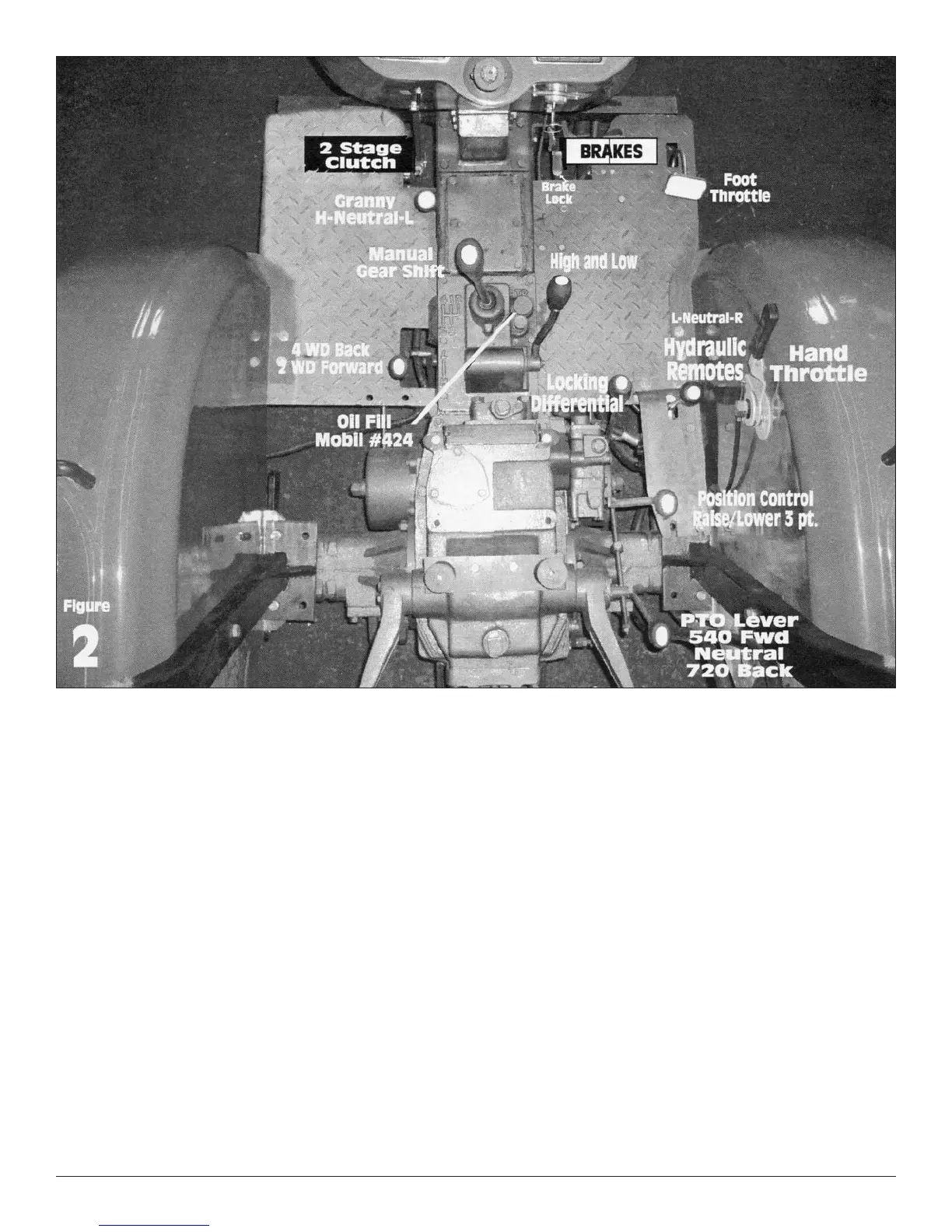

FIGURE 2:

It locks both rear wheels for getting out of the toughest of

conditions. It operates in addition to 4WD. It must be

slipped into gear only when moving very slowly at low

RPM and double clutching. Once in, it will stay in automat-

ically without being held in until you are free of the stuck

position.

Position Control—is the raise-and-lower lever for your three-

point implements. This lowers your implements by moving

lever forward from the neutral position and raises them

when moving the lever toward the back position.

PTO Engagement Lever—is to be left in the center position at

all times unless you are planning use with a PTO run imple-

ment. Moving the lever forward puts it in 540 RPM and to

the rear past neutral is the 720 RPM speed setting.

Tires—the standard tires are a 9.50 X 24 in the rear and 16 X

6.00 in the front. Optional are the Dual Trax brand 12.9 X

18 rears and 16 X 7.50 fronts. These meet both R1 and R4

standards (ag and industrial design).

Figure 3—

Tire Pressures—Suggested 20 lbs rear and 25 lbs front.

Pressures can be adjusted up by 10% depending on loads put

on the tractor.

Lower Link Arms—left and right are the points at which you

attach the ears of your three-point implement. The ears on the

implements used on this equipment are Category I in size.

Likewise, so are the holes in these lower links.

Top Link—this is the top adjustable arm that attaches to the top

or third attaching position of your three-point implements.

The top link is responsible for properly adjusting most imple-

ments on how they are to angle or face. Make sure once your

adjustments are made that you lock them with the tightening

nut.

Lower link lift arms—these help make sure your implement is

evenly leveled or in some cases you may want the reverse.

You may want a road blade to tilt and thus is of a turn-buck-

le type design. Make sure once you have your desired adjust-

ment, that you lock that positioning by tightening the nut at

the top.

PTO—is the Power Take Off which attaches to your implements

via a shaft. It is of a standard 6 spline type that is universal.

Implement shafts are made to lock onto this PTO shaft from

the tractor. Have the dealer show you how this lock works on

the various implements you use. Never operate this PTO

when you are off the tractor. Standard PTO speed is 540 RPM

or revolutions per minute. Over 90% of the implements you

—continued on page 6

Loading...

Loading...