40

ALTA

Installation, Operating & Service Instructions

110327-02 - 7/20

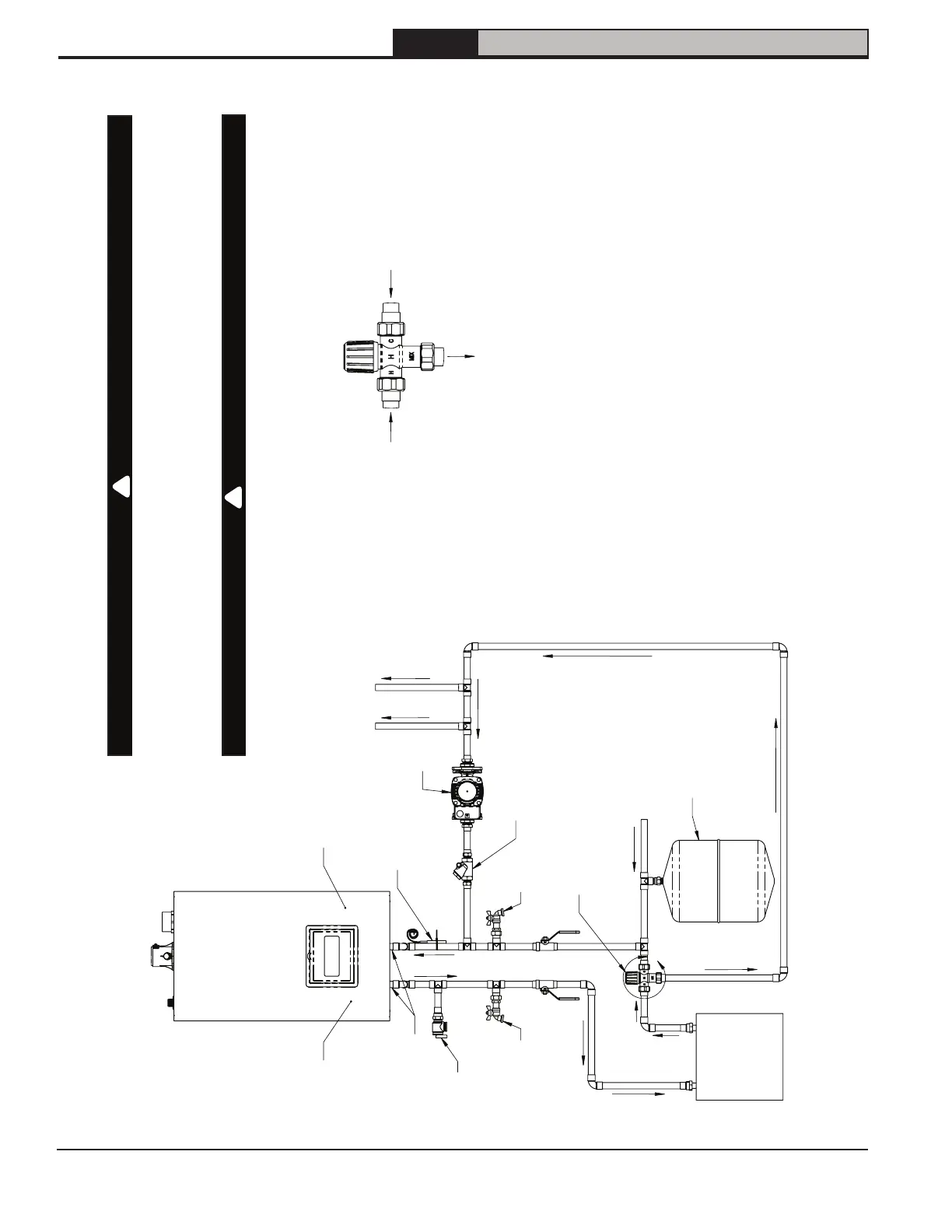

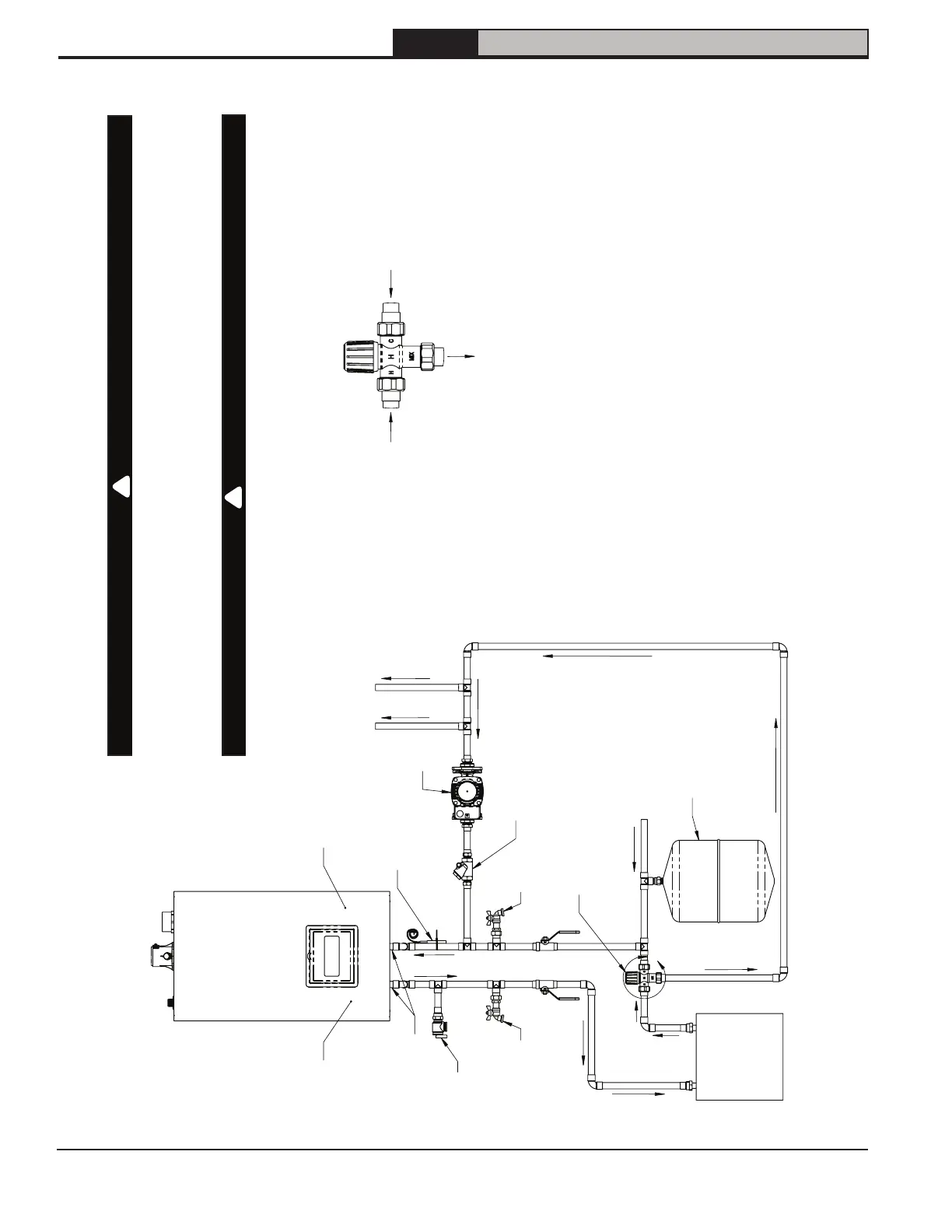

11 Domestic Water Piping (continued)

NOTICE: Heating System piping omitted for clarity.

NOTICE: Installer is responsible for piping configurations to provide proper flow rates and

meet local codes.

DANGER

Scald hazard. Under certain conditions this boiler can deliver (DHW) at temperatures

in excess of DHW setpoint in boiler control. A field supplied ASSE 1070 listed anti-

scald valve is required as part of this boiler’s installation when DHW recirculation

issued.

CAUTION

Component Damage.

Excessive heat from soldering could damage gaskets at connection between DHW

adapters and boiler. Solder connections to DHW adapters before installing gaskets.

!

!

A

DHW

Pressure

Relief Valve

Drain

Valve

Buffer Tank

(2-6 Gal.)

(optional)

Drain

Valve

ASSE 1070 Listed

Anti-Scald Valve

(required)

Cold Water Supply

Recirc. Temp. Sensor

(P/N 108703-01)

Expansion Tank

(Req'd if cold

water supply line

has check valve)

Flow Check

Valve

Recirc.

Pump

Hot Water

To Fixtures

*Supplied with boiler

DHW Strainer*

(inside boiler)

DHW Flow Limiter*

(inside boiler)

DHW Adapters*

(G 1/2" to 3/4" sweat)

Detail A

(Scale 1 : 4)

Cold Water Supply

Hot Water

(From Boiler)

Hot Water To Fixtures

Figure 11-3: DHW Piping with Recirculation

NOTICE: Additional wiring and control settings required for DHW

recirculation:

• Connect recirculation pump to "Aux Pump" terminals per Figure 13-2.

• Connect jumper, time of day clock or momentary push button to "Aux

T'Stat" terminals per Figure 13-3.

• Secure recirculation temp sensor close to boiler on cold water line.

• Connect recirculation temperature sensor to "Header sensor" terminals per

Figure 13-3.

• Turn DHW comfort mode "on". See Section 16 Operation and Table 16-11.

Loading...

Loading...