18 Impulse Second Stage Service & Repair Manual

© 1997 U.S. Divers Co., Inc.

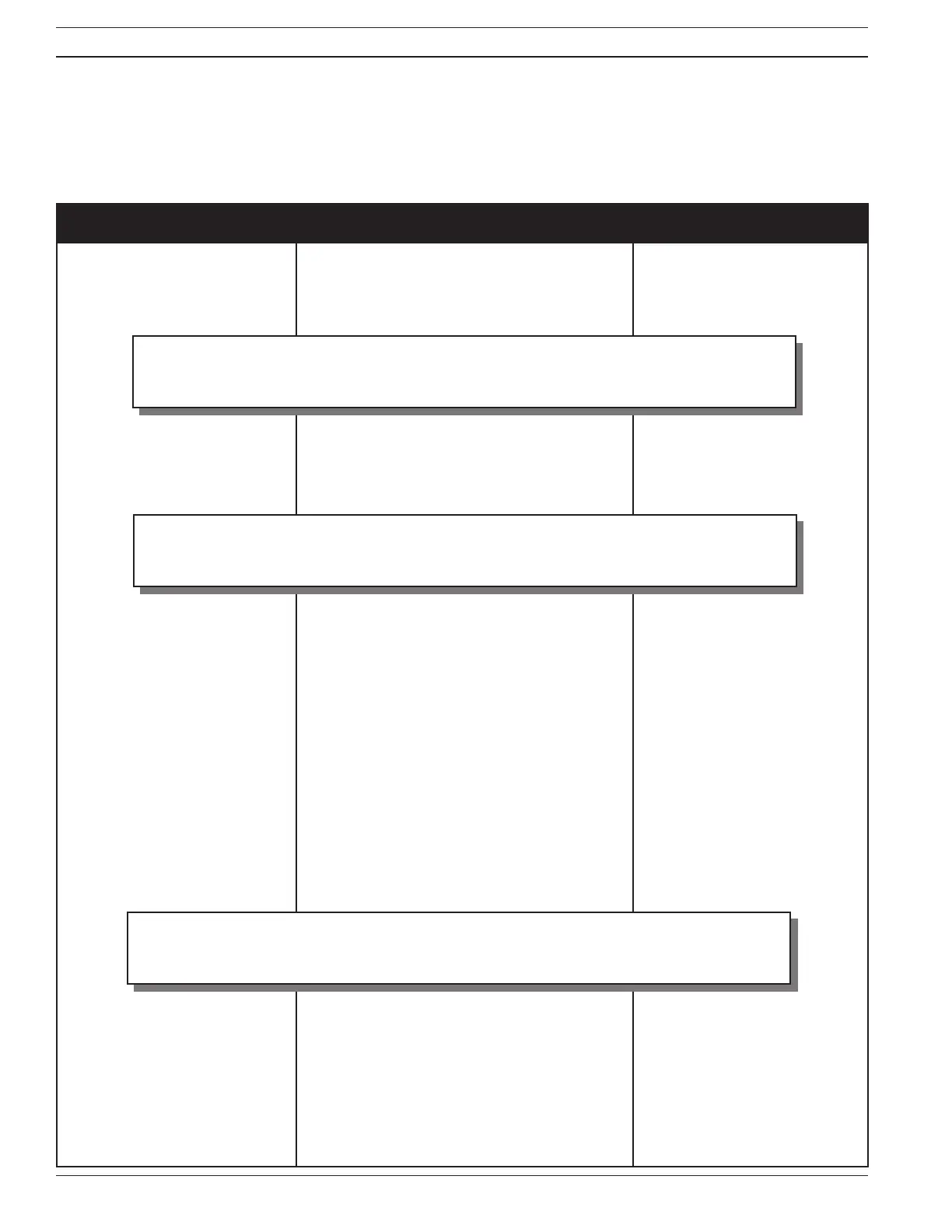

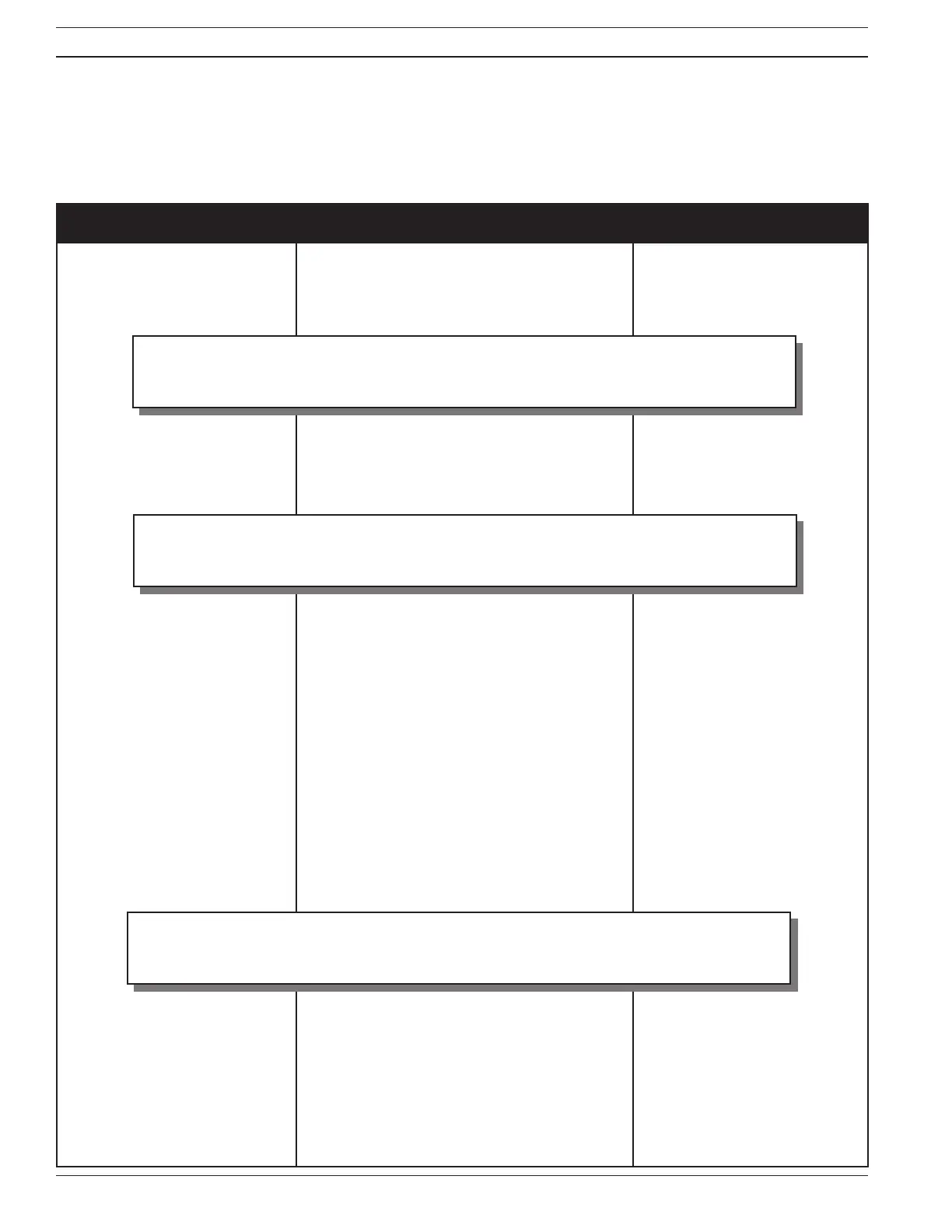

LUBRICANT / CLEANER APPLICATION SOURCE

Dow Corning

®

111 All O-rings; threaded metal parts Dow Corning Corp.

(pure silicone grease) P.O. Box 1767-T

Midland, MI 48640

800-248-2481

Silicone Pump™ General preservative/conditioner for McNett Corp.

(non-aerosol silicone milk spray) hoses, instrument console boots, etc. P.O. Box 996

Bellingham, WA 98227

800-221-7325

Anti-Seize Lubricant #80208 M.A.S. cylinder adapter - female threads Permatex Industrial Corp.

(food grade - U.S.D.A. approved Micra ADJ adjustment screw 705 N. Mountain Rd.

for conformance to MIL-A-907-E) Newington, CT 06111

(860) 520-5000

ChromeSafe™ Degreaser and acid bath for reuseable U.S. Divers Co. P/N 0201-09

(ultrasonic cleaning solution) stainless steel and brass parts.

Oakite #31 Acid bath for reuseable stainless Oakite Products, Inc.

steel and brass parts. 50 Valley Road

Berkeley Heights, NJ 07922

White distilled vinegar Acid bath for reuseable stainless "Household" grade

(100 gr.) steel and brass parts.

Liquid dishwashing detergent Degreaser for brass and stainless steel parts, "Household" grade

(diluted with warm water) general cleaning solution for plastic, rubber,

and anodized aluminum parts.

Snoop™ Leak testing Nupro Company

400 E. 345th St.

Willoughby, OH 44094

216-951-7100

Table A

Recommended Lubricants & Cleaners

(All Aqua-Lung Regulators)

CAUTION: Silicone rubber requires no lubrication or preservative treatment. DO NOT

apply silicone grease or spray to silicone rubber parts. Doing so will cause a chemical

breakdown and premature deterioration of the material.

CAUTION: Aerosol spray silicone should be avoided because (1) common aerosol

propellants may attack plastic and rubber parts, and (2) because only a slight amount

of silicone remains after the solvent evaporates, and provides no lasting benefit.

CAUTION: DO NOT use muriatic acid for the cleaning of any parts. Muriatic acid,

even when strongly diluted, can harm chrome plating, and may leave a residue that is

harmful to O-ring seals and other parts.

Loading...

Loading...