28

Adjustment info

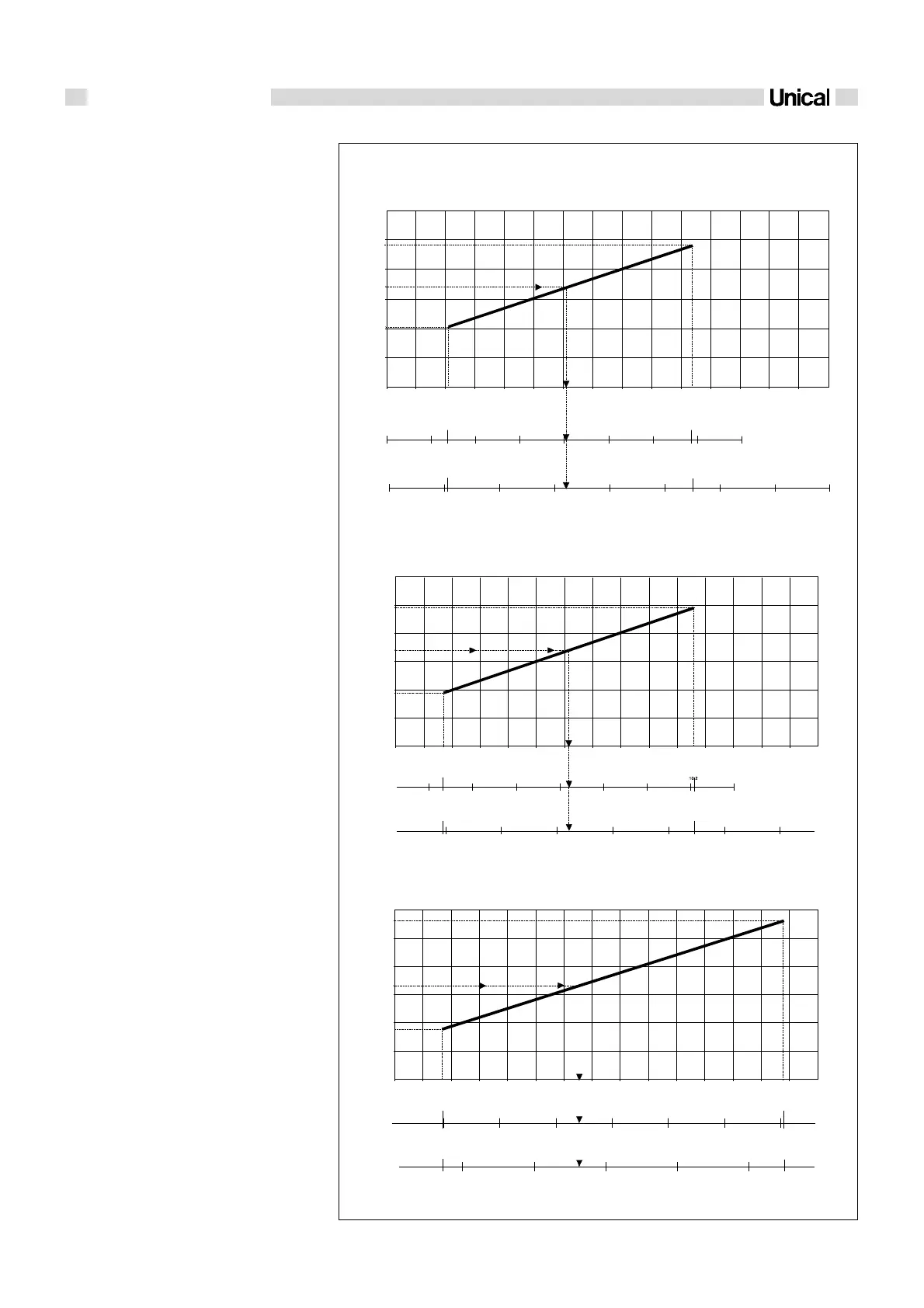

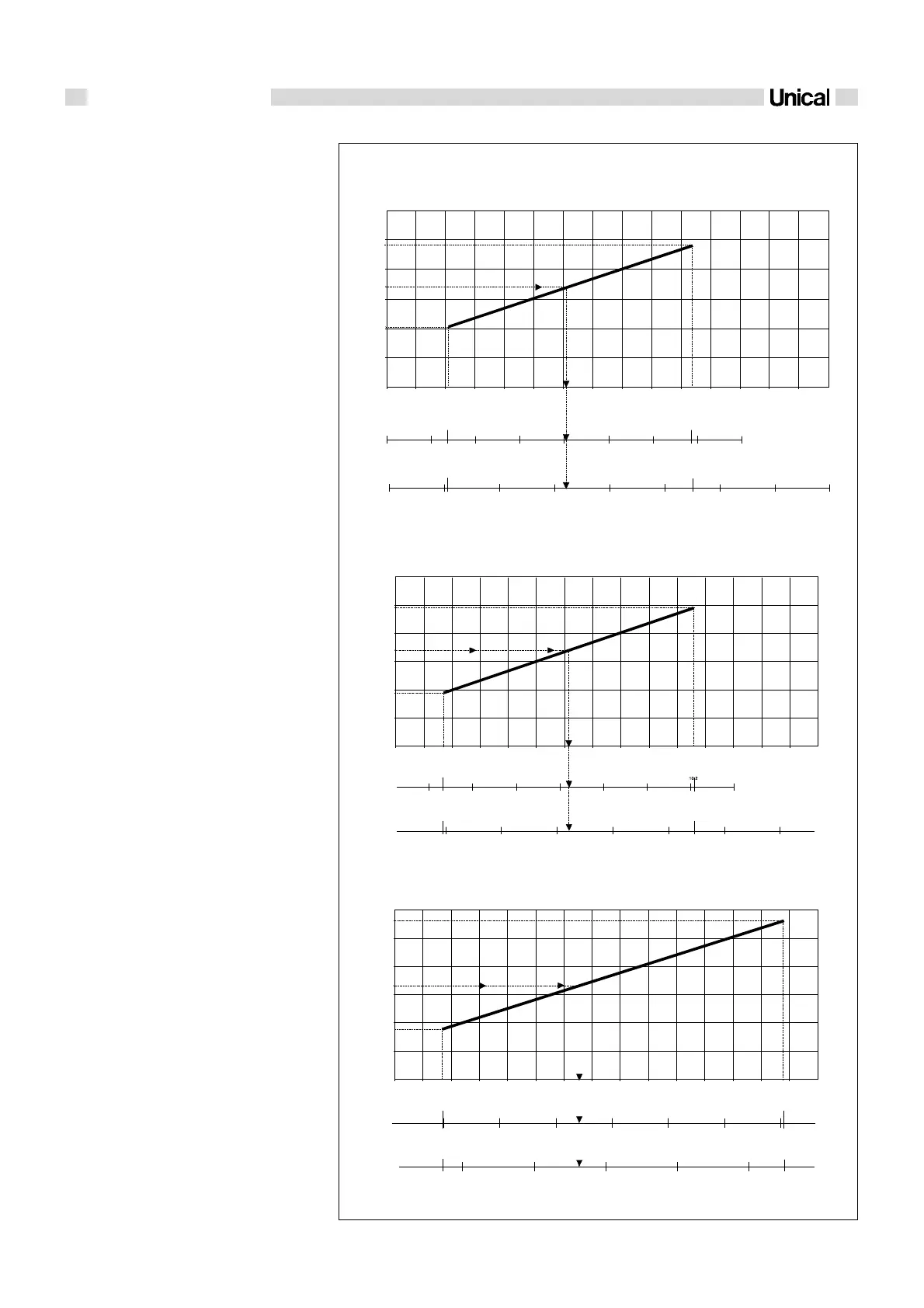

fig. 34

IVEN 04 CTN 24 F - IVEN 04 RTN 24 (A)

IVEN 04 CTFS 24 F - IVEN 04 RTFS 24 (B)

IVEN 04 CTFS 28 F - IVEN 04 RTFS 28 (C)

5

10

0 1 2 3 4 5 6 7 8 9 11 12 13 14 15

0

10

15

20

25

5,3

27,6

5

10

15 20 25 30

0

35 40

6,9

34,2

Natural gas G20 - 20 mbar

0 1 2 3 4 5 6 7 8 9 11 12 13 14 15

0

10

15

20

25

Natural gas G20 - 20 mbar

24,5

9,95

1,7 10,6

0 5

10 15

20

25

4,8

27,3

5

10

15

20 25 30 35

40

0

Natural G20 - 20 mbar

2.8 ADJUSTEMENT OF

THE OUTPUT TO

THE C.H. SYSTEM'S

NEEDS

Connect the pressure gauge to the burner as

previously shown in fig. 30, switch on the boi-

ler in heating mode and proceed as follows:

- Wait about 50 sec. to allow the burner pres-

sure to reach the standard operating va-

lue.

- Check the pressure value and through the

diagrams of fig. 34 estimate if the boiler

output is correct for heating needs.

- If not, act on the adjuster ''1 CH-POWER''

(fig. 31) on the panel board and turn it to

reach the desired value (clockwise to in-

crease, or anticlockwise to reduce the

pressure).

- Then establish the pressure value corre-

sponding to the required output.

Example:

Assuming that the heating system which is

using a IVEN CTN 24 F boiler has a total ab-

sorption of 17 kW. Using the graph ‘’A’’ in fi-

gure 34 it is possible to determine the burner

pressure, which will be:

- 6,18 mbar if the boiler runs on natural gas

- 20,5 mbar if the boiler runs on propan gas.

- 16,3 mbar if the boiler runs on butan gas.

Acting on potentiometer 1 - CH POWER set

the pressure resulting from the diagram.

GAS PRESSURE BURNER DIAGRAM CORRESPONDING TO

THE SYSTEMS OUTPUT

Loading...

Loading...