Model Square

drive

Impact

rate

Maximum

Torque

Noise level Vibrations

level

m/s

2

Pressure dB(A) Power dB(A) Pressure dB(C)

‘‘ N.m k* k* k* k**

942 PC3 1/2 1650 861 91,1 3 108,1 3 < 130 3 9,57 1,44

1/4 PT

Ø 10 mm

3/8 "

Model Free speed Air consumption Working pressure Weight Dimensions

rpm l/min bar kg mm

942 PC3 10000 127 6,2 1,3 111x61,5x173

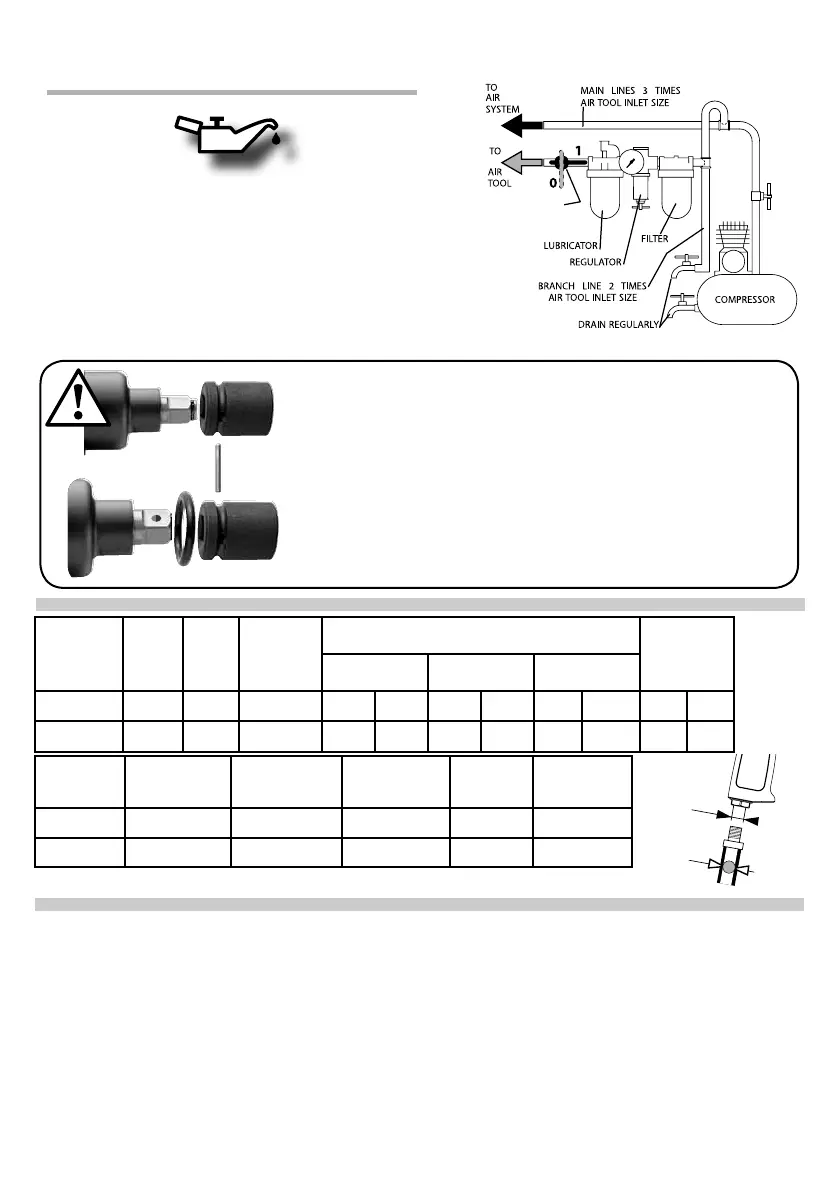

• BEFORE EACH OPERATION, CHECK:

- Only use suitable USAG sockets and flogging spanner accessories, (‘‘IMPACT’’) as well as

safety devices, bush and pin for mounting one of these cases on a drilled driving

square.

- The drive square condition (no marks, cracks or excessive wear).

- The condition of the safety devices (bush and pin) on the drilled square as well as the draw

bead on the non-drilled square.

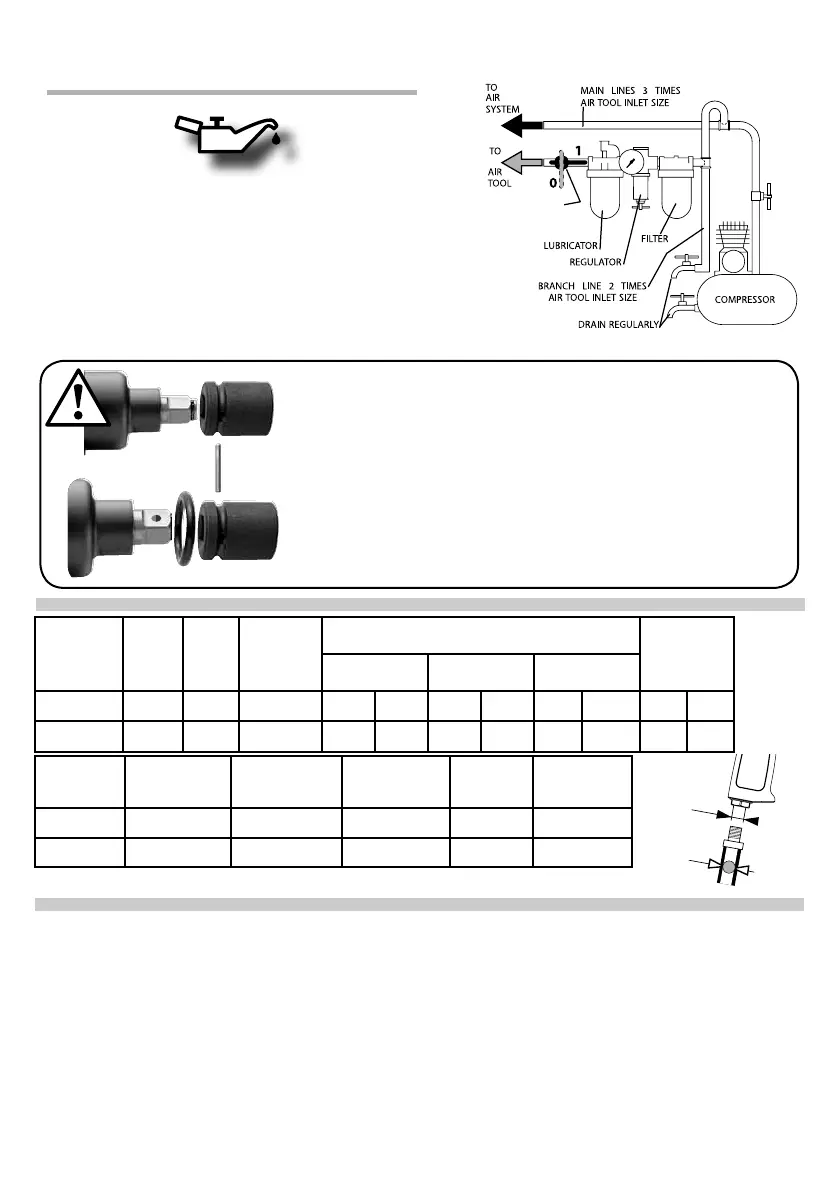

PLACING THE MACHINE IN SERVICE

EMERGENCY

GATE VALVE

* k = measurement uncertainty in dB ** k = measurement uncertainty in m/s²

LUBRIFICATION

Always use of an air line lubricator with these machine. We recommended the

following Filter-Lubricator-Regulator Unit: USAG N.580.

Every eight hours’ operation, if a lubricator is not used on the compressed air

network, inject 1/2 to 1cm

3

through the machine’s inlet connection.

DATE CODE POSITION

IS PRINTING INTO THE HOUSING. (ABOVE RATING PLATE)

EXAMPLE:

16 XXXXXXXXXX

Loading...

Loading...