Ncrtel Bend In9 the

causes

bends !

Use

only

not

be fltied ln +helr

push

rods excess lve ly

such o-rlngs whlch nl ll

actua I

p

laces.

Tne

and

Tne

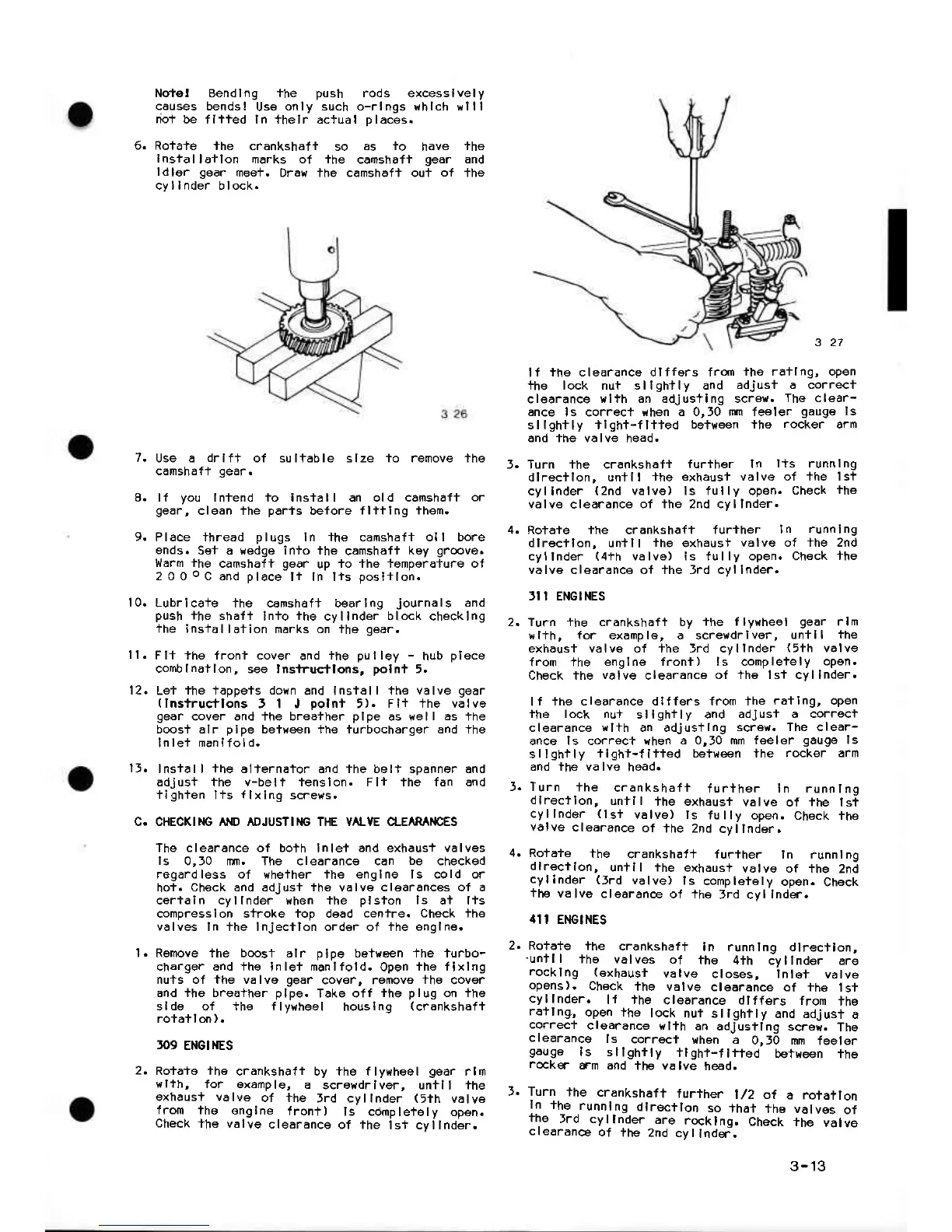

Roia+e

+he crankshaft

so

as io

have

Insialla+lon

marks of ihe

camshafi

gear

ldler gear

mee+.

Draw the camshaf+ ou+

of

cv I lnder b lock.

7.

Use a

drlf+

of sulfable slze to remove lhe

camshaff

gear.

lf

you

Intend to insiall an old camshaft

or

gear,

clean ihe

par+s

before

flttlng ihem.

Place thread

plugs

In the camshaft ol I bore

ends.

Sef a wedge in+o the

camshafi

key

groove.

I,Jarm fhe

camshaft

gear

up

io the fempera+ure of

2 0 0

o

C and

place

li ln lis

posl+lon.

Lubr i cate ihe camshaf+ bear Ing

journa

I

s

and

push

+he

shat+

info

ihe

cy I Inder

b

lock check Ing

ihe

ins+alla+ion marks on +he

gear.

ll.

Fl+ ihe front cover

and

ihe

pulley

-

hub

plece

comblnaflon,

see Instruqtlons,

polnt

5.

12.

Lei

ihe

tappeis

dorn

and Install +he valve

gear

(

lnstructlons

3 | J

polnt

5).

Fl+ +he valvo

gear

cover and +he brea+her

plpe

as \{ell

as

the

boost alr

pipe

bel-lreen ihe tu.bocharger and the

lnle+

man i

fo

ld.

lJ.

Insiall

+he

al-ternaior and l'he beli spanner and

adjus+ the v-belt tenslon. Fll' the fan and

ii

gh+en

lis llxing screws.

C. CHECKING AND ADJUSTITIG THE YALVE CLEARANC€S

The clearance of bo+h

lnlei

and exhaus+ valves

ls

0,30 Fn. The clearanca can

be

checked

regardless of whe+her ihe englne ls cold or

ho1.

Check and adjust th6 valve cloarances of a

certaln cvllnder when the

Dlston

ls

at lfs

comoression stroke too dead

cenfre. Check ihe

valves

ln +he Injecl-lon order of the

englne.

Rgmove +he boost alr

Dloe

beivroen +he turbo-

charger and the

Inlei

manlfold.

Open

ihe flxlng

nu+s of the valvg

gear

cover, removg

+he

covor

and lhe brea+her

plpe.

Take off

the

plug

on +he

slde of the

flywheel houslng

(crankshafi

rotatlon ).

'O9

ENCINES

Ro+a+e the

crankshai't by the flywheel

gear

rlm

v.lth,

for ex6mple,

a

screwdr lver, unill the

exhaus+ valve

of the

lrd cyllnder

(5th

valve

f.om ihe

englne

fron+)

ls cömpletely

open.

Check

lhe valve

clearanca

of the

lsf cvilnder.

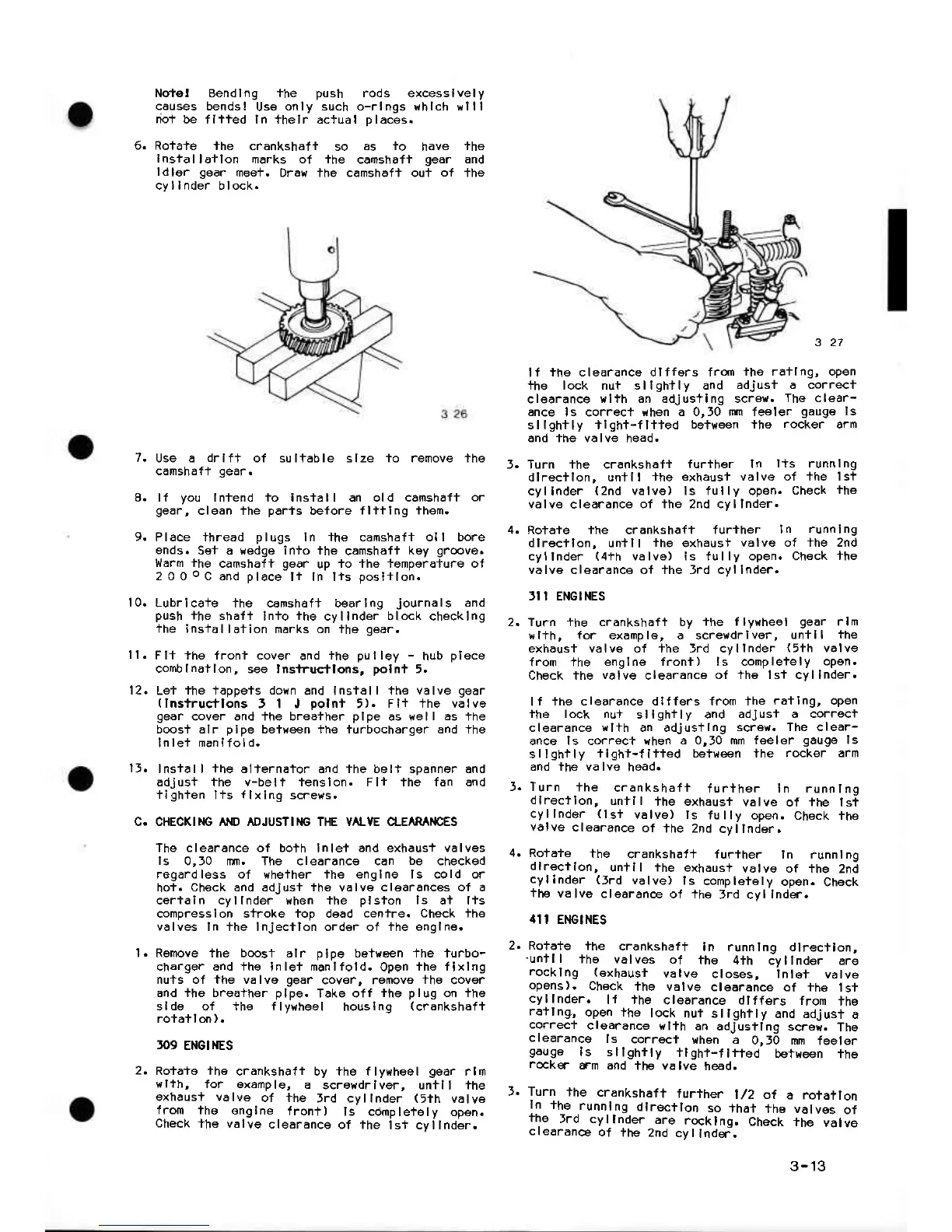

327

lf

the clearance dlffers f.dn

iho ra+lng, open

the lock nut sllgh+ly and

adjust a correct

cloarance

vllth an adjus+lng screx.

Tho clear-

ance

ls correc+

*hen a 0,30 |Im feeler

gauge

ls

sllghtly +lght-fltled

beiween the

rocker

arm

and the va lve

head,

J. Turn the crankshaf+

furiher ln

lts runnlng

dlrec+lon, un+ll

-ihe

exhausl valve of +he lst

cyllnder

(2nd

valvo) ls iully open.

Check

the

valve

clearance

of the znd cyllnder.

4.

Ro+aie

the

crankshaft

fur+her

In

runnlng

dlrecilon, un+ll

+he

exhausi

valve of +he 2nd

cyllnder

(4ih

valve) is fully open. Check

-the

valve clearance of +he Jrd cvllnder.

]I I ENGI NES

2. Turn +he crankshaf+ by

+he llywheol

gear

rlm

|{l+h, for example, a screwdrlvor,

untll

the

exhaust valve of +he frd cyllnder

(5th

valve

frorn ihe

englne front) ls cornp

leiel

y

open.

Check the

valve

clearance

ol +he lsi cyllnder.

lf

the clearance dlffers from +he

ra+lng, open

ihe lock nu+

sllgh+ly and

adjus+ a correc+

clearance

wl+h

an adjustlng

screw. The clear-

ance ls co.rect rhen

a 0,30 mm feeler

gauge

Is

sllghtly

tlght-fltted bet{een the

rocker arm

and the va lve

hoad.

J. Turn

+he

crankshafi

furlher In runn

I n9

dlrectlon,

untll

+he exhausi

valve

of

+he

lst

cyllnder

(lsl

valve) ls

fu lly

open. Check tho

valve

clearance

of

+he 2nd

cyllnder.

4.

Ro+aie

the

crankshaf+ {uriher

ln runnlng

dlrectlon,

un+ll ihe

exhaus+

valve of

ihe 2nd

cylinder

(frd

valve)

ls

completely

open.

Check

the valve

clearan@

of +he

frd cvllnder.

4II ENGI NES

2. Ro+a+e

the

crankshaft

In runnlng dlrecllon,

-untll

lho valves

of

the

4th cvllndsr are

rocklng

(exhausi

valve

closss, lnlol

valve

opens),

Check

the valve

clearance of l-he

ls+

cyllnder.

ll the

clearance dltfers

from

the

ratlng,

open lhe

lock

nui sllghfly

and adjust

a

correct

clearance

erl+h an

adjustlng screw.

The

clearance

ls

correci

when a

0,J0 nm

feelor

gauge

ls sllghily

ilghi-flited

between

the

r€ker

ö.m and

the va lve

head.

l. Turn

lhe

crankshaft

furlher

l/2 of

a rotailon

ln

lhe

runnlng

dlrectlon

so

+ha+

the valves

of

the

frd cyllnder

are

rocklng.

Check

the

valve

crearan@

of +he

2nd

cVllnder.

9.

10.

3-13

Loading...

Loading...