6.

8.

5.

Bearlng

hous

I ng

-

R6p I

ace bearlng

houslng,

ll

surtacos or- the

seallng rlng

notably

rorn or scraiched.

fhe bearl ng

groovgs

are

Roiatlng

paris

Chock ihe balanclng of the roiatlng

parts

rSQr

s6allng

r'lng

Rgplace

damaged, vorn ol-

hardened

seallng rlng

Turbo

houslng

and +urblne

houslng

Check th6

houslngs

for

any damage or cracks

caused bv

the coniact of the roior or detects

du6 io posslble

overheatlng.

l4lnor damages can

be accepted,

bu+ ofher*lse

replace

ihe

houslng.

Assemb I lng the iurbo

After cleanlng and Inspectlng ihe turbo

parts

carefully

and replaclng ihe faul+y

paris,

assemble ihe

+urbo. Perlorm ihe assenbly In the

reverse

order compared io dlsassenbly.

Pl6ase

pay

6++entlon io followlng

polnts:

The rotatlng

parts

should be bölanced |rlth an

accuracy of

1,44

gfln

a+ both ends. Ensure

ihat

you

tlnd

the marks

you

nade durlng dls-

essembly

Indlcatlng the rela+lvo

posltlons

oJ

dl fforeni parls.

Place +he

lock rlngs In +helr

posltlons

wlth

fhe

chanfared

slde lowards l-he bearlno.

8

l0

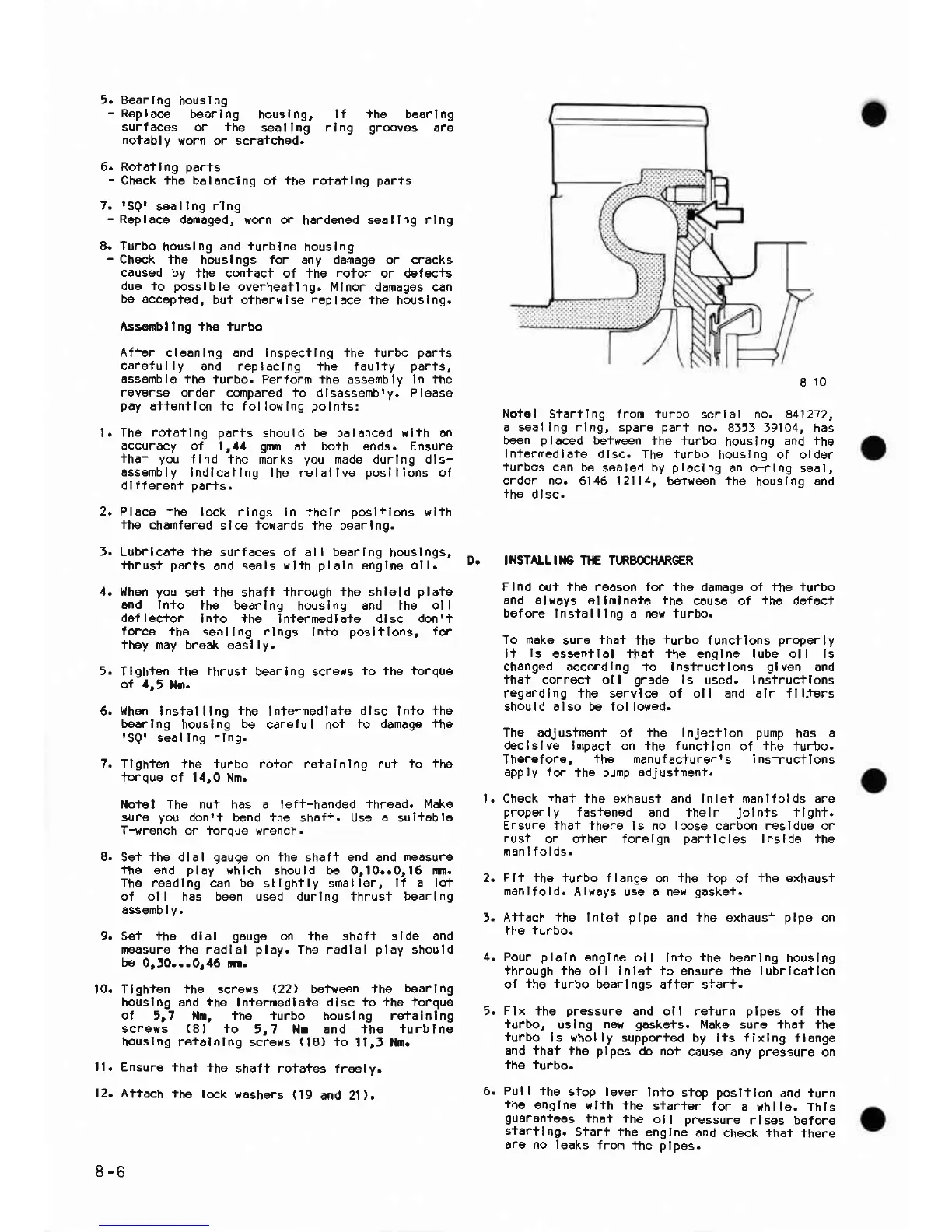

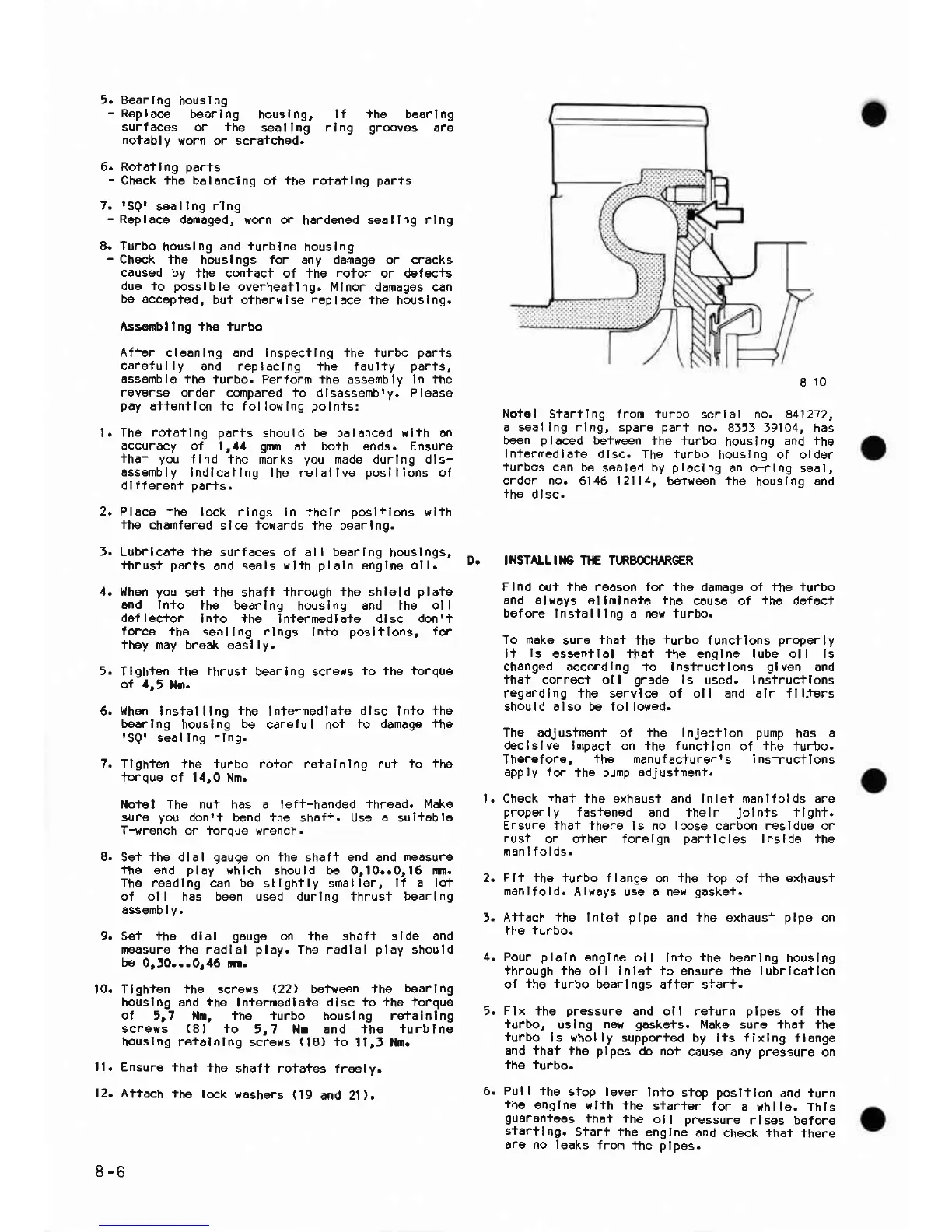

Notof Siarflng fron turbo

se.lal rto. 841272,

a seallng rln9, spare

par+

no. 8f5f f9104,

has

been

placed

bein€€n

+he +urbo

housing

and ihe

lntermedlafe

dlsc. Tho iurbo

houslng of older

turbqs can be

sealed

by

placlng

an o-rlng seal,

order no. 6146 12114,

bei{e€n fhe

houslng

and

fhe dlsc.

IISTALL

I

IG Tlf TIRB&MRGER

Flnd ouf fhe reason for fhe danage of the turbo

and alvrays el

lmlnate

the

cause of

+he

defeci

before lnstalllng

a ner

turbo.

To make

sure

ihat

lhe turbo functlons

properly

It

ls

essonilal +hat the englne lube ol I ls

ch€nged acco.dlng to Insfruc+lons

glvon

and

that

correcl oll

grade

ls used. lnstruc+lons

regardlng the servlce of oll and alr fll;iers

shou ld also be follolrsd.

The

adJustmeni of

ihe

Injectlon

pump

has

a

dgclslve lmpac't on ihe functlon

of

+he

turbo.

Therefore,

ihe manutac+urerr

s Insirucilons

apply for

+he

pump

adjusiment.

Check +ha+ ihe exhausi and lnlet manlfolds are

properly

fas+ened and thelr

jolnis

tlght.

Ensure ihat there

ls

no loose carbon resldue or

rust

or o+her forelgn

par+lcles

lnslde the

mån lfolds.

Fl+ the turbo flange

on

ihe iop

of

the exhaust

manlfold.

Always use a ner

gaskei.

Attoch

the

lnlet

plpe

and +he exhaus+

plpe

on

the

turbo.

Pour

ploln

englne ol

I Inio

+he

bearlng houslng

through the ol I Inlel io ensure +he lubrlcatlon

of

the iurbo

bearlngs af+er start.

Flx

the

pressure

and oll return

plpes

of ihe

turbo,

uslng

ner gaskets.

Make sure +hai ihg

turbo

ls wholly supporied by

lts flxlng flange

and that

fhe

plpes

do not

cause any

pressuro

on

the turbo.

Pull +he

stop

lever lnlo

stop

poslilon

önd +urn

ihe

englno

wlth +he

siartsr

for a xhlle.

Thls

guarantges

that ihe

ol

I

Dressure

rlses bg{ore

startlng.

Star+ the

englne

and check +hai

there

are no leaks

from

+he

DlDes.

f.

Lubrlcate fh€ surfaces of all bearlng

houslngs,

thrust

parts

and

seals ,lth

plaln

englne oll.

4. |{h€n

you

set

+he

shati

+hrough +hs shlsld

plate

and ln+o

ihe bearlng

houslng

and +he ol I

def lector

lnto +he lniernodla+e dlsc donrl

force

the seallng rlngs

lnto

posltlons, for

tlEy may

broak oasl ly.

5.

Tlgh+en

ihe ihrusi

bearlng scrers

to the torque

of

il,5

In.

}{hen

Insfal llng

ihe

ln+ermedlaie

dlsc

lnto

the

bearlng

houslng

be

careful noi

io damoge

ihe

'SQr

seallng

rlng.

Tlgh+en the lurbo roior relalnlng nu+ to

the

torque of

l4r0 Nn.

Not€l The nu+ has a lef+-handed

+hread. lvake

sure

you

donr+

bend +he shaf+,

tjse a

sul+able

T-wrench

or torque

wrench.

Sgt the dlal

gauge

on lhe shaft end and

meösurg

lh€ end

play

vhlch should be 0,10..0,16 rn.

The readlng can

be

sllghily smaller,

lf a lo+

of ol

I has

beon used durlng thrus+ bearlng

assemD ty.

9. Set the dlal

gauge

on the shaf+ slde and

tp€sure ihe

radlal

play,

The radlal

play

should

b€

0,50...0,46

rn.

Tlghi€n

fhe screws

(22)

b€tve€n ihe

bearlng

houslng and the

Iniormedla+e

dlsc fo +he lorque

of 5r7

n, the turbo

houslng

reialnlng

scrers

(8)

io

5,7 Nn €nd lhe

iurblne

houslng reiölnlng scre{s

(18)

to

ll,3 l{n.

Ensuro thal

the

shafi rotates

froelv.

Attach

ihe

lck rashers

(19

and 2'l ).

D.

||.

12.

10.

8-6

Loading...

Loading...