Liquid Level Indicator

10 Installation and Operations Manual

Note Install a Varec manhole or inspection hatch, if there is none located within arms

reach of the tape pipe location. Refer to In-service Tank Installations later in this section

for hatch and manhole installations.

Locate the float at a position inside of the tank where agitation on it will be at a minimum.

Install a deflector if the product stream is close to the float. Contact Varec if agitators will cause

excess float disturbances. Vertical pipe runs must be plumbed and perpendicular to prevent

the tape from binding inside the pipe.

The user must attach the gaugeboard to the tank by welding or bolting the supplied

gaugeboard support brackets. If the environment is such that welding cannot be performed,

the user can construct a support structure with 3-inch [76 mm] pipe or conduit close to the

outside of the tank. The brackets can be welded to the support structure at another location,

if necessary, and the pipe structure assembled at the tank site. Refer to In Service Tank

Installations later in this section for additional details.

Warning The user should comply with all applicable regulations, codes, and standards.

For safety precautions, the user should refer to the appropriate industry or military

standards.

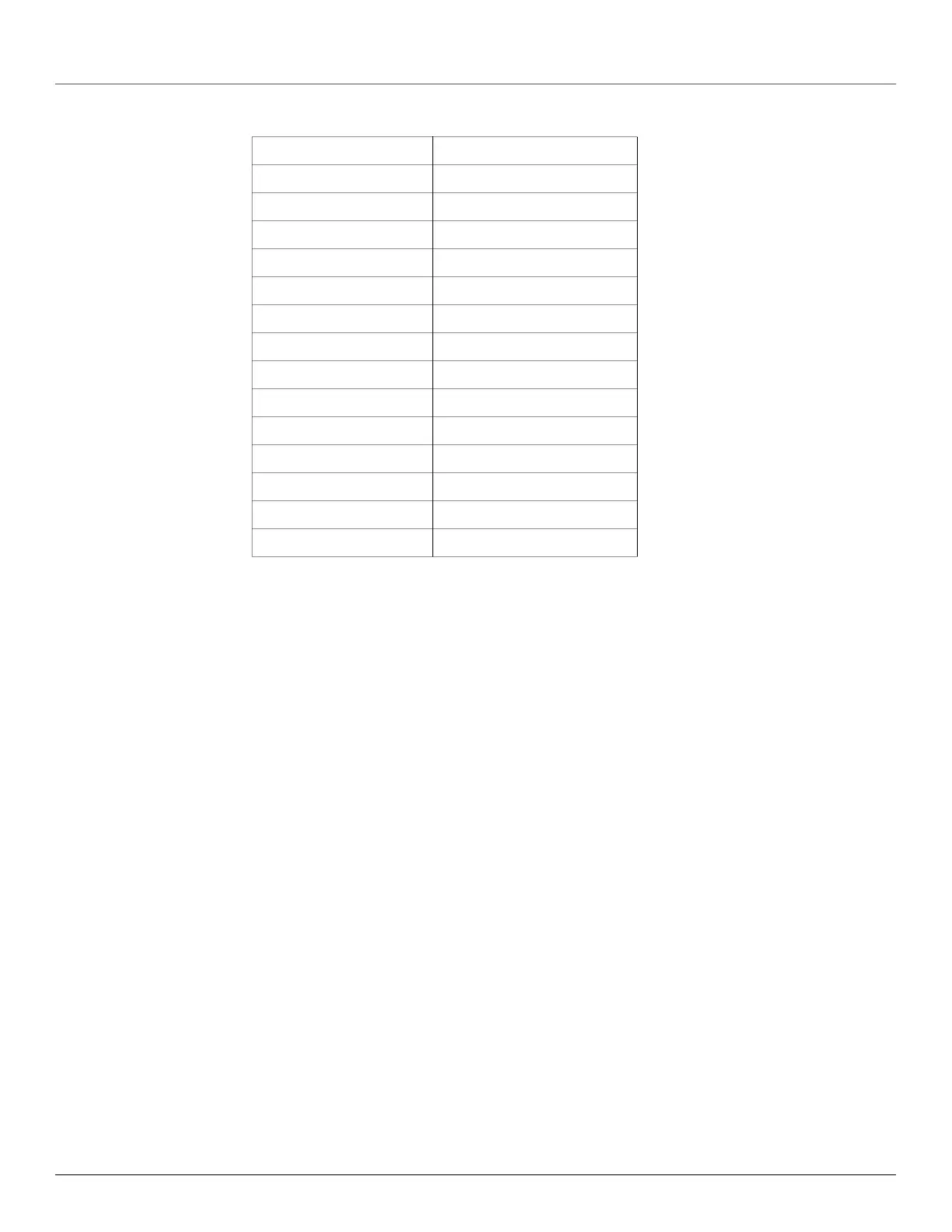

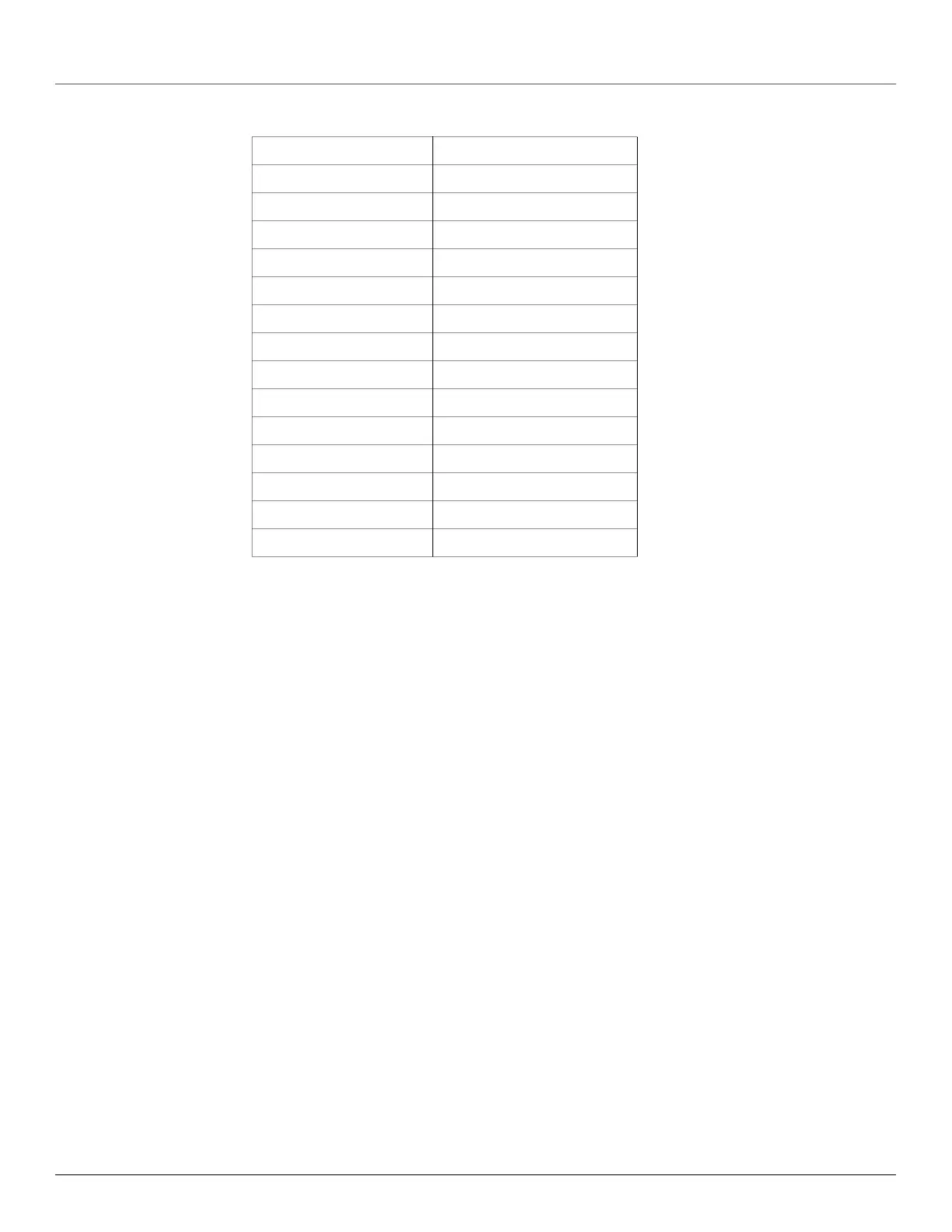

Table 6: Typical Tools, Equipment, and Materials List

Tool/Equipment

Breathing equipment Pick

Cable cutter Pipe cutter

Chalk Pipe taps/dies

Chalk line Pliers

Clean drop cloth Plumb bob

Compass Protractor

Drill bits Screwdrivers

Electric drill Sheet metal shears

Hole cutters Shovel

Level String

Light oil Tank hand gauge

Loctite 262 Vice

Loctite 567 Welding equipment

Long measuring tape Wrenches

Loading...

Loading...