Maintenance

Varec, Inc. 53

can prevent problems from occurring. Periodic cleaning, lubrication, and replacement of worn

parts stops trouble before it starts.

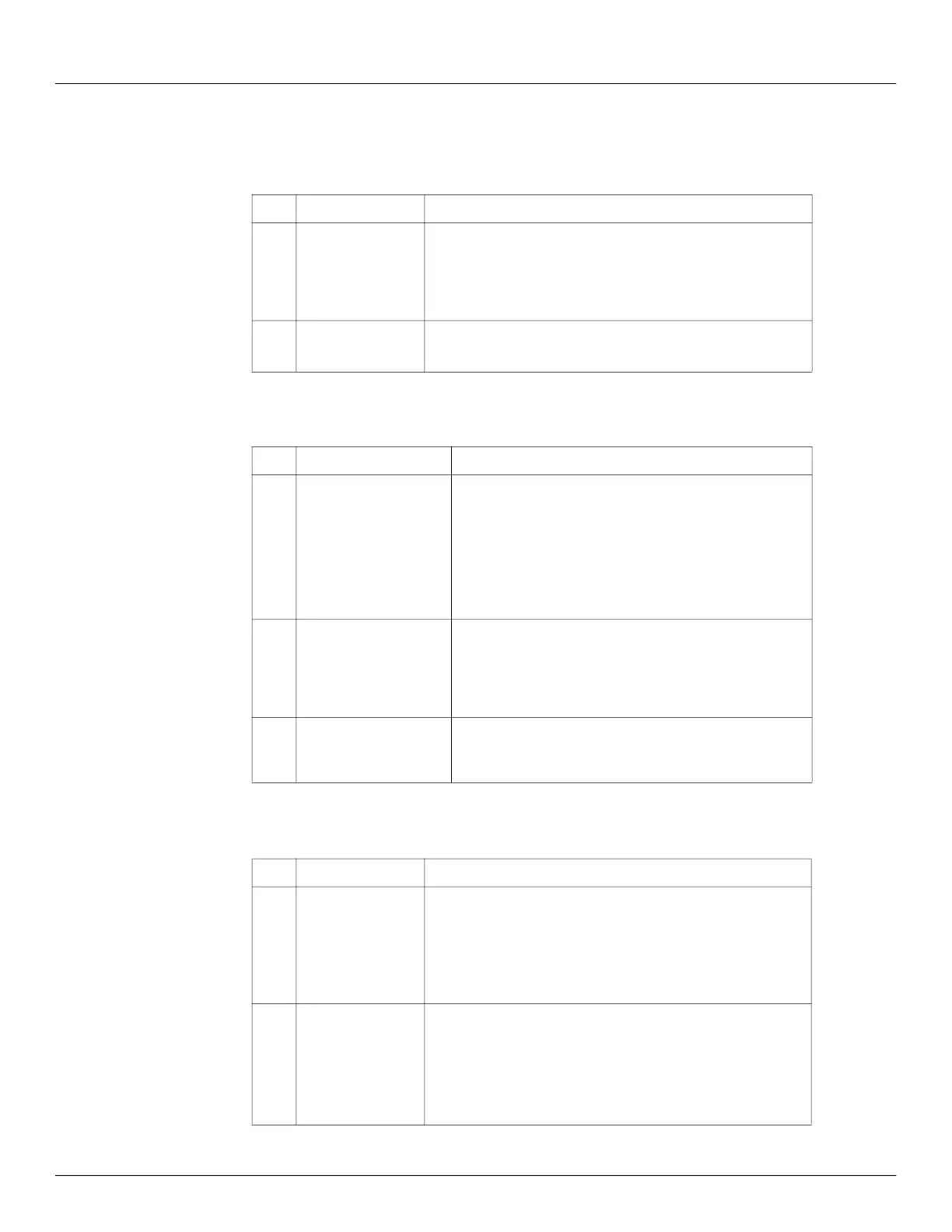

Table 9: Indicator at Ground Level (Tank Not Full)

Possible Cause Action

1 Cable broken? Yes

Replace cable.

No

Go to 2.

2 Float detached? Yes

Re-attach.

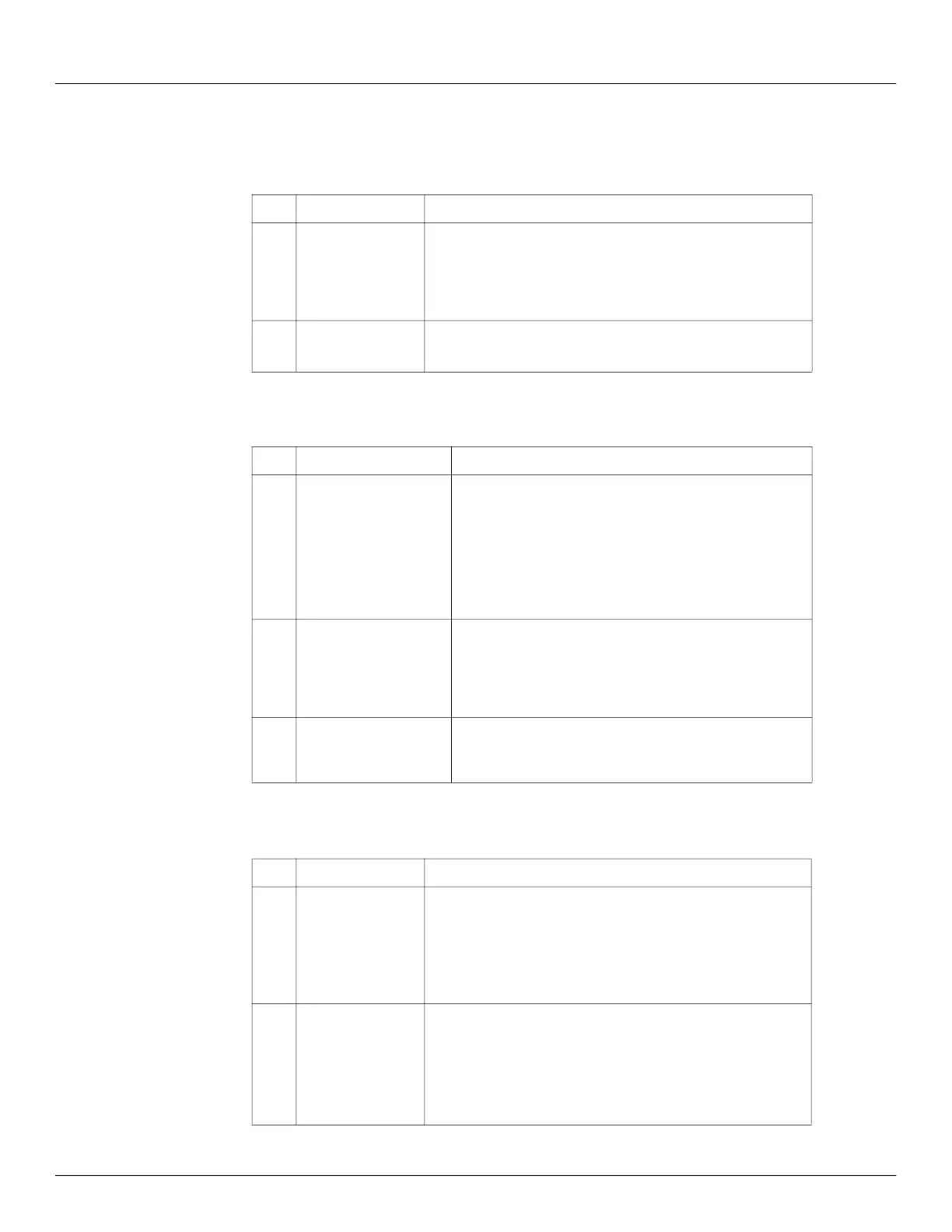

Table 10: Gaugeboard Indicator Stopped

Possible Cause Action

1 Cable stuck? Yes:

• Check cable path.

• Check for frozen sheave shafts (repair/replace).

• Check for frozen accessory shafts (repair/replace).

No:

• Go to 2.

2 Pipes dirty? Yes:

• Clean with automotive type spray degreaser.

No:

• Go to 3.

3 Indicator or

gaugeboard slides dirty

or damages?

Yes

• Clean. Repair/replace.

Table 11: Calibration Repeatibility Unstable

Possible Cause Action

1 Indicator or

gaugeboard slides

dirty or damaged?

Yes:

• Clean with automotive type spray degreaser. Repair/

replace.

No:

• Go to 2.

2 Tape/cable off

elbow pulley?

Remove elbow covers.

Yes:

• Reseat and lubricate pulley shafts.

No:

• Go to 3.

Loading...

Loading...