11

ANY WARRANTY IS VOID!

This concerns in particular the installation of the anodes. Non-original SPW anodes lead to malfunctions!

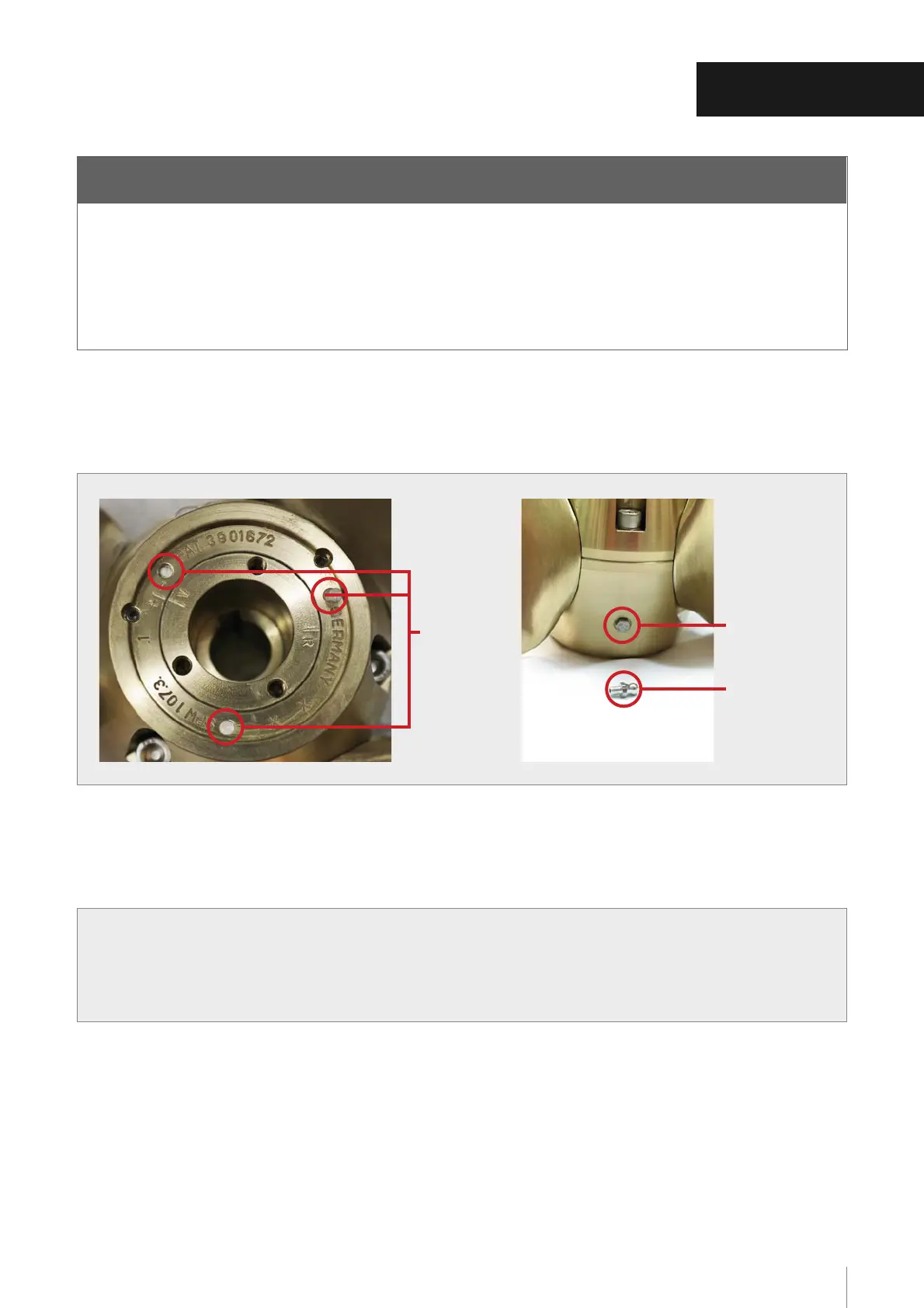

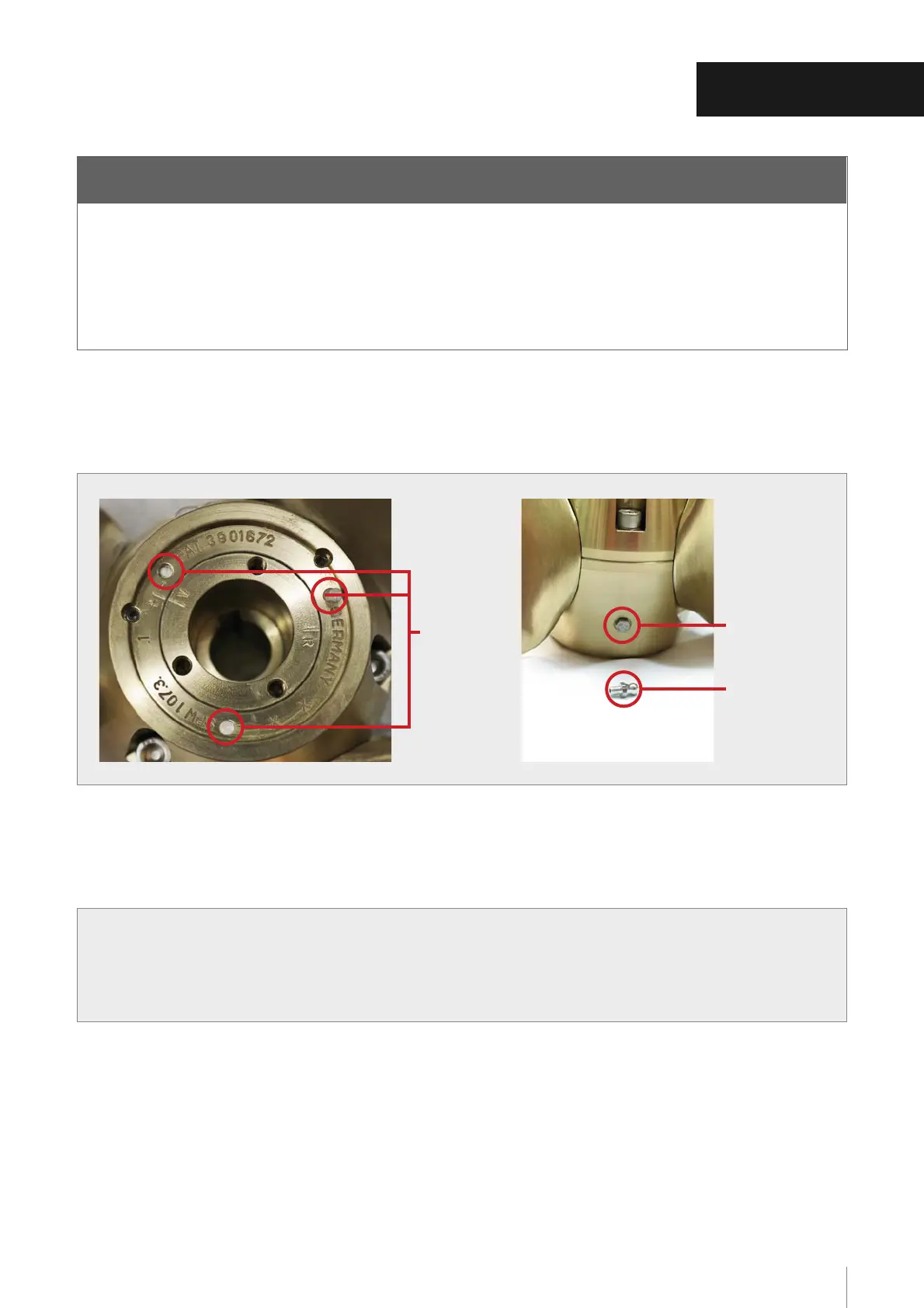

anodes - screws - locking screws and EP/SAL special grease

We explicitly point out that the following spare parts may only be installed as original SPW parts:

Important note:

anode drill holes on top of the prop.

stop to reverse stop to allow the grease to work through the propeller. Stop to pump when enough grease comes out of the

supplied with the tools. Further remove the zinc anode! With each pump of the grease gun rotate the propeller from forward

with a high viscosity grease of a hydrophobic nature. Remove the cap screw (5) and screw in the lubricating nipple which is

The VARIPROP needs to be greased a minimum of once a year. The VARIPROP body should always be completely filled

out here!

grease squeeze

Stop greasing if

nipple M5

Lubrication

Cap-screw (5)

regular white grease (sterntube-grease ) !

Factory supplied special grease EP/SAL is recommended and available from your VARIPROP distributor. Avoid

“heavy” turning at the absorber area is normal and necessary for the function !

substantially protected against wear. At rotating the blades by hand, you can feel the shock-absorber function. This

The integrated shock-absorber reduces unpleasant operating noises. The pitch stops are

VARIPROP-anode to give the zinc good contact with the propeller

use a zinc anode onto the shaft if possible. Use fine sandpaper to clean the aft of the end boss and the forward face of the

Make sure that you always keep the zinc anode in good condition. The VARIPROP must be protected by a lot of zinc, so also

Loading...

Loading...