11

i

j

k

l

F

G

h

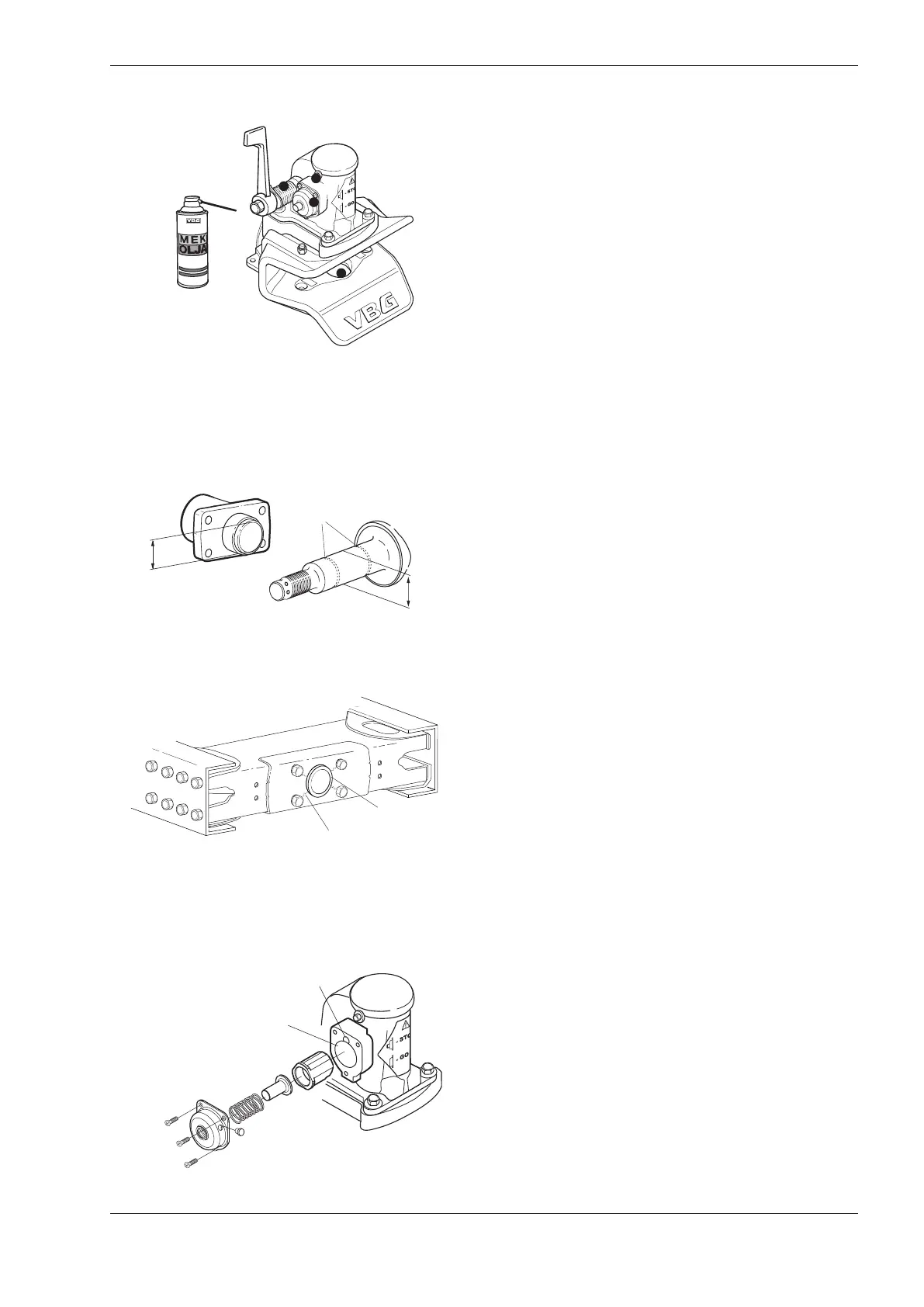

Lubricate the coupling with VBG mechanism oil. For

maximum effect, the coupling must be open when it is

being lubricated.

•

Lubrication points (see drawing on the left)

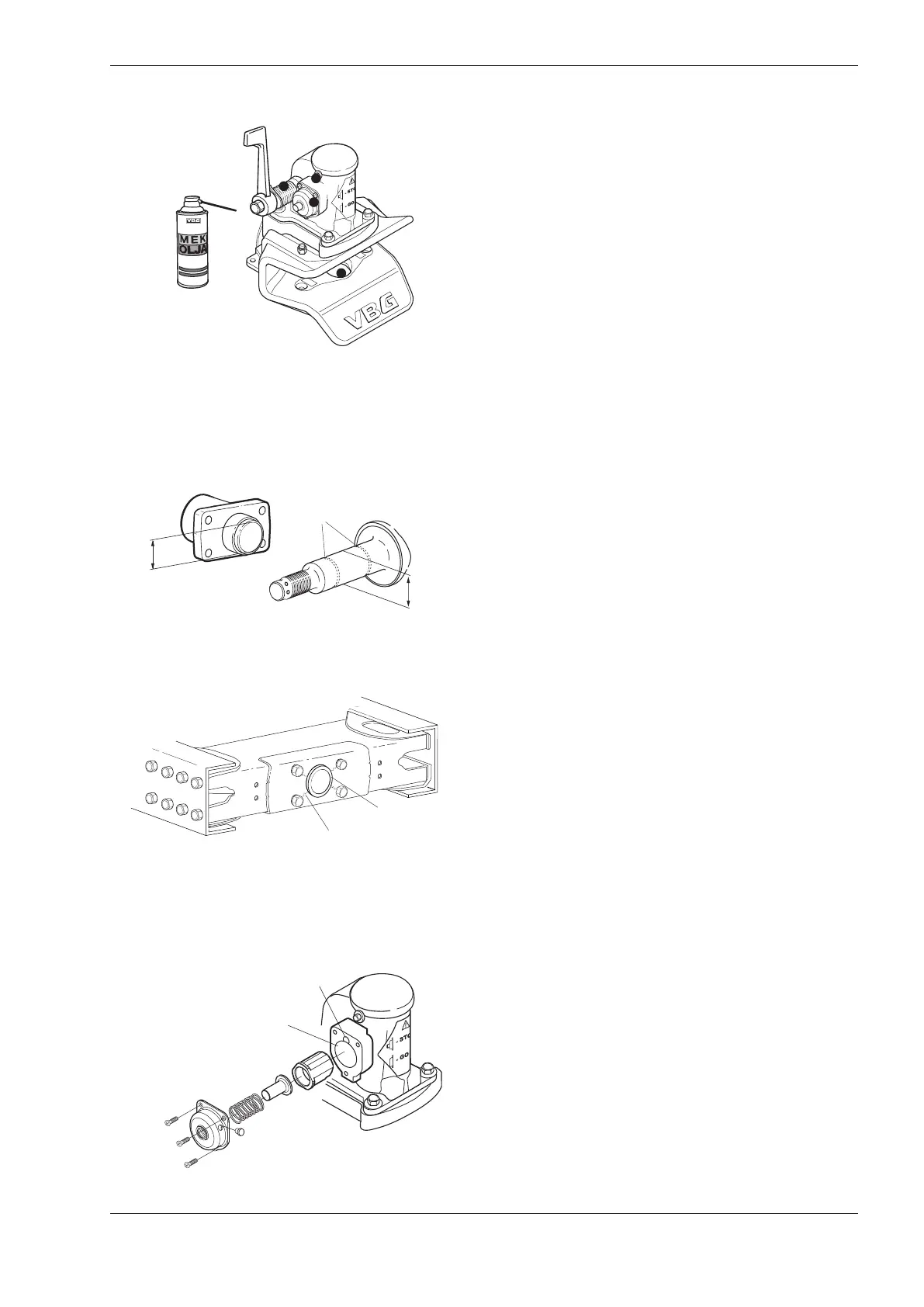

Attachment check

• Remove the coupling jaw and clean the shaft of rust

and rubber residue.

• Check that the coupling jaw is neither bent, nor has

cracks or any damage due to electrolysis.

• Check the wear limits as per below:

F max. Ø 67.2 mm (without bushings)

G min. Ø 61.6 mm

Change of Indicator/locking pin

• Loosen the three bolts holding the lid.

• Remove remaining parts.

• Clean the bearing surfaces for the locking pin (k) and

lubricate with thin grease. Check that the centring pin

(l) is correctly fi tted.

• Mount the parts according to the fi gure.

• Check that there is no cracks forming or deformation

on the drawbeam (i) and that the drawbeam sleeve (j) is

properly attached.

Tightening torque M20 quality 8.8 (dry): 370 Nm.

Loading...

Loading...