2

a

b

d

c

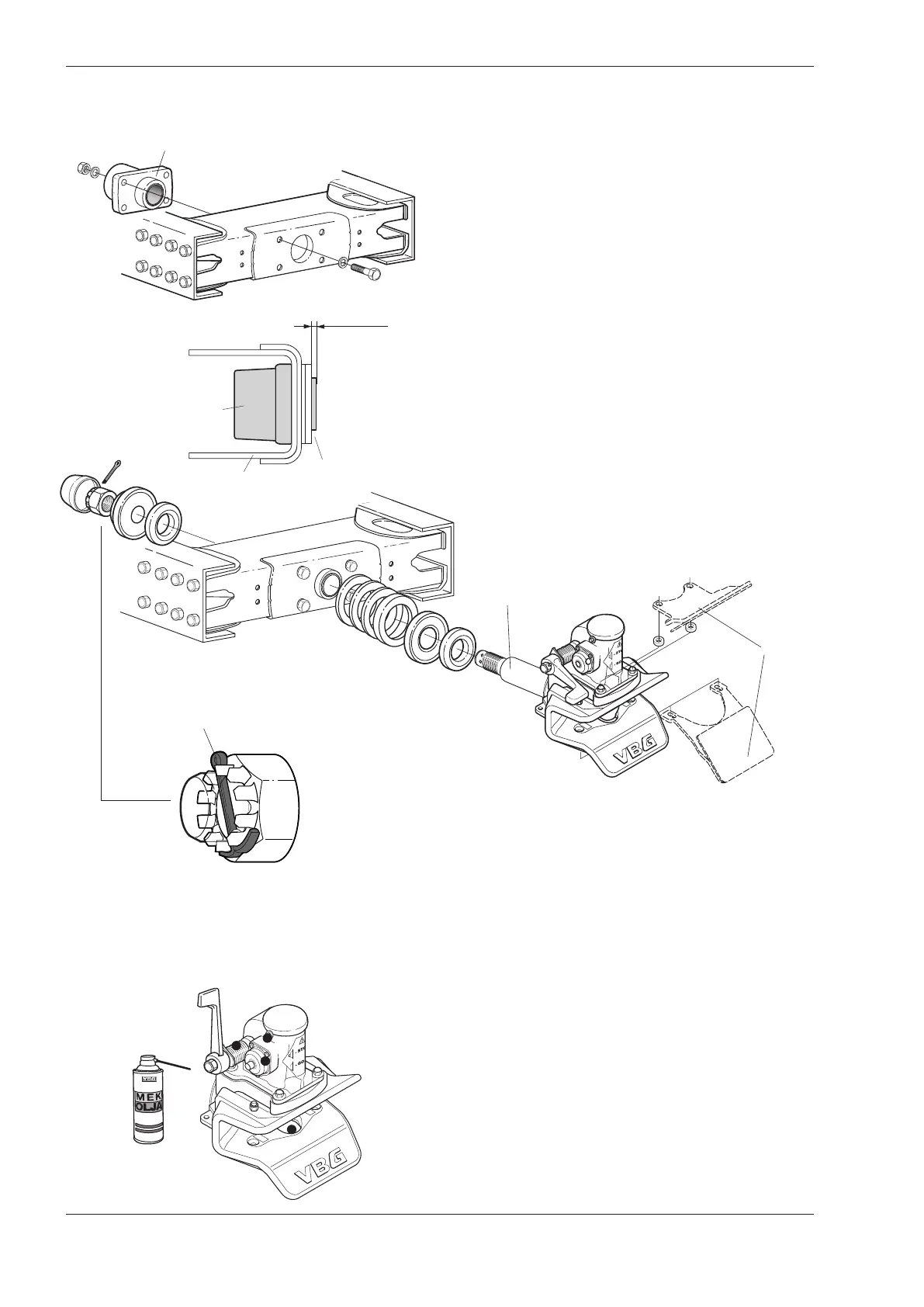

5–8,5 mm

Mounting instructions

• Lock the castellated nut with split pin. It is very impor-

tant that the split pin is completely within the gates

of the castellated nut and is secured as per the pic-

ture.

• Lubricate the the castellated nut and the nut cover

with grease.

• Mount the nut cover.

• When the coupling is reassembled after service, a new

split pin must always be used.

Function check

Carry out the function check on page 5.

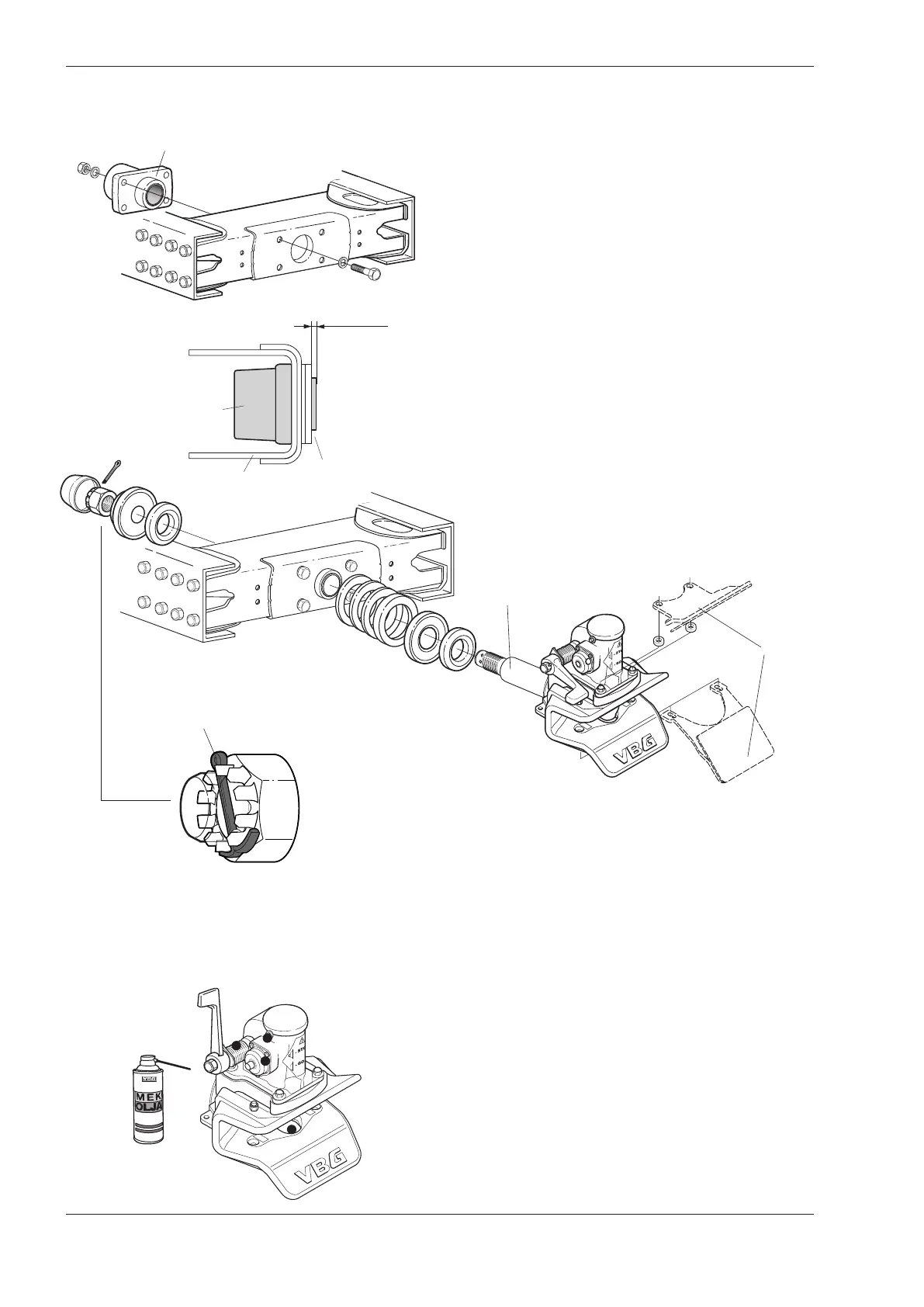

Lubrication

Lubricate the coupling weekly with VBG mechanism oil

or similar thin oil. For the maximum effect, the coupling

should be open when it is being lubricated.

VBG do not recommend the use of central greasing

systems.

•

Lubrication points (see adjacent drawing).

Mounting of drawbeam sleeve

• Mount the drawbeam sleeve (a) with four screws as

per the drawing. Flat washers with a minimum hardness

of 200 HB must be under both bolt head and nut.

Tightening torque M20 quality 8.8 (dry): 370 Nm.

Mounting of coupling

• Lubricate the coupling jaw (b) and all its threads with

grease. This prevents rust and makes future service

work easier.

• Fit the attachment parts as shown in the fi gure. Fit the

bar spacer washers on the drawbeam sleeve collar so

that the dimension 5–8,5 mm is achieved. The number

of washers depends on the thickness of the drawbeam,

and the 10 mm washer should be outermost. See fi gure.

Mount accessories such as the coupling mouth exten-

sion (c) according to the drawing.

Tightening torque castellated nut 1500 – 2000 Nm.

Drawbeam

sleeve

Drawbeam

Spacers

Loading...

Loading...