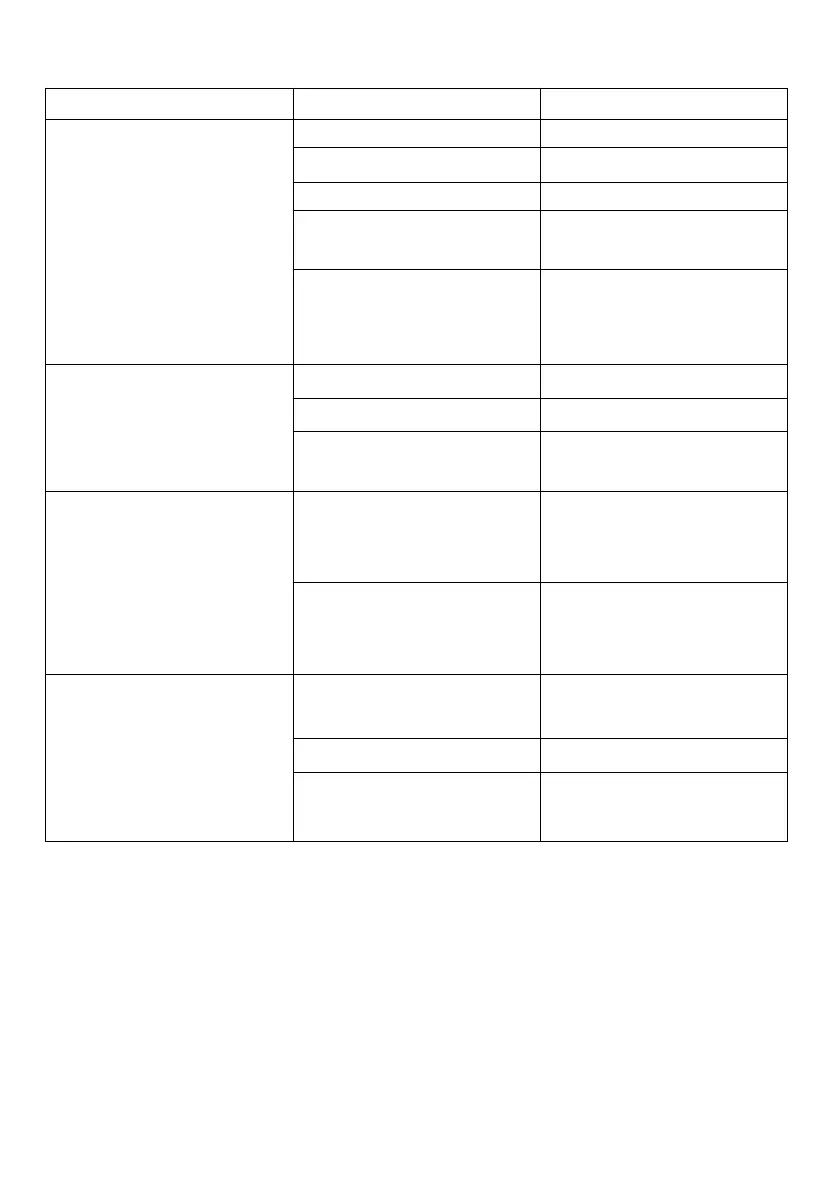

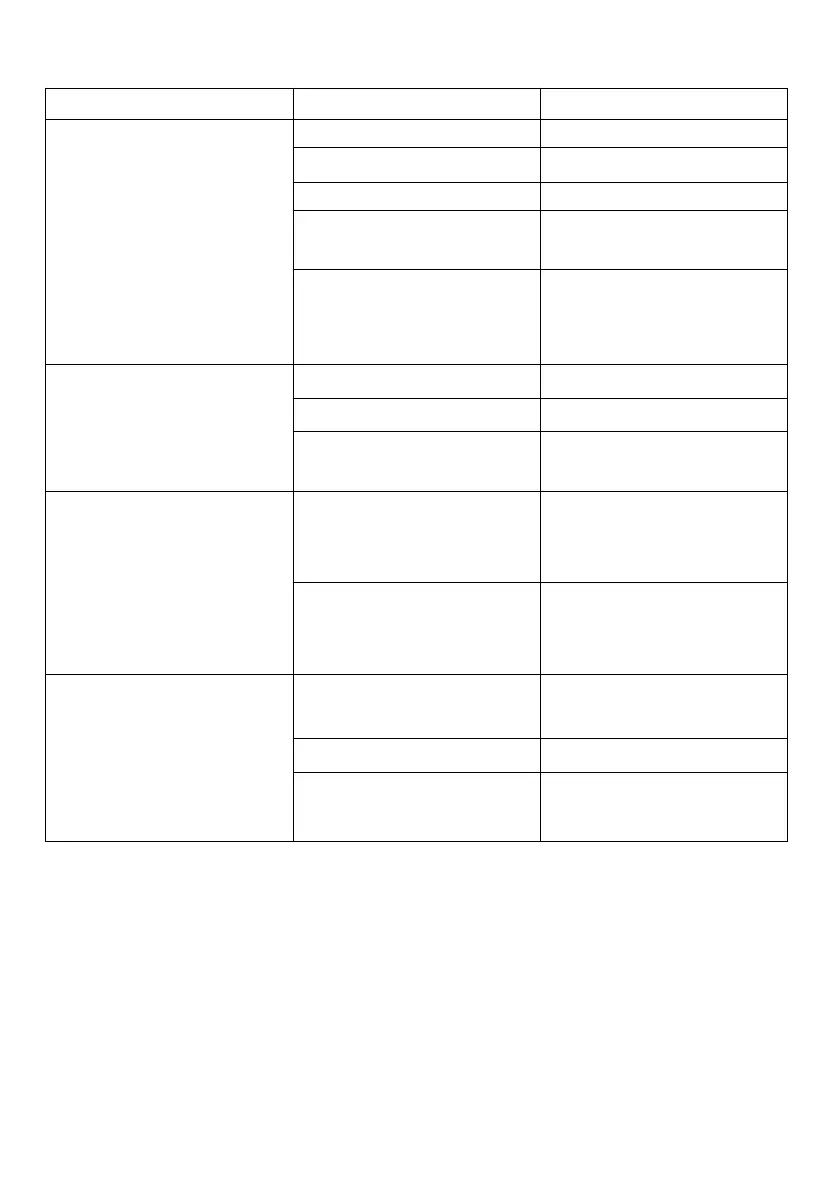

TROUBLE SHOOTING INSTRUCTION

Magnetic holder has no

suction.

Repairing the power

supply.

Electromagnet short

circuit or burn out.

Repair or replace the

magnetic base.

It is not adsorbed on

steel parts.

Change or thicken the

adsorption surface

(thickness > 15mm).

The machine won't work

after the power is on.

Connecting the power

supply.

The brush does not

contact the commutator.

Magnetic seat suction is

weak.

The adsorbed workpiece

is too thin.

Change or thicken the

adsorption surface

(thickness > 15mm).

Change the adsorption

surface or temporarily

weld the thick adsorption

Elliptical holes appear in

the drilling holes.

The vibration caused the

fastener to loosen.

Tighten the fastener after

correcting the verticality.

The drill cuts only on one

side.

There is debris on the

adsorption surface.

MAINTENANCE AND STORAGE

NOTE: Please remove the plug before maintenance.

1. After each use, clean the bottom of the magnetic seat drill and keep it properly.

2. Please butter the track in time when the slide is not smooth.

3. Please check the electrical protection device regularly.

4. Whether grounding is reliable.

5. Please check in time during the rainy season.

Loading...

Loading...