NAME OF PARTS

( ).

Emergency Operation switch

3.EMERGENCY OPERATION SWITCH

In case thebatteries in the remote controller areworn out, or remote controller is at fault, use

Emergency operation switch

Cooling only type

Every time the switch is pressed,it changes in sequence of COOL STOP.

The following table shows the condition of set temperature, fan speed and deflector during

emergency operation.

4.HORIZONTAL LOUVER BLADE

Hold the knob and move the deflector to change right/left airflow direction. Be careful not to adjust

the deflector during operation as the fan is rotating at a high speed and may pinch your fingers.

Mode

Set temperature

Deflector

Fan speed

SwingHigh

Cooling

24

C

5

22

The places of e different models maybe different, but all of the

e ¡ °¡ ¡ ¡ ¡ ¡ ±

mergency operation switch of

mergency operation switches are showed by the icon .

POWER

COOL

WARM

SLEEP

TIMER

COOL MODE

indicator lamp

Sleep indicator

lamp

Timer indicator

lamp

Run indicator

lamp

HEAT PUMP MODE

indicator lamp

or

or

CUSTOMER COPY

Name of Customer:

Model:

Serial Number:

Date of Purchase / Date of Installation:

Installation Done By:

Name of Service Center:

Commissioning:

10. Run the machine for 30minutes

& check for the following.

a) Vibration / abnormal noise observation.

If yes provide detail.

i) Checked for earthing with the unit_______V

(Voltmeter reading must be less than 3V)

Ii) Supply between L & E - 230 10% ______V±

E

V

L

N

iii) Supply between L & E - 230 10% ______V±

Output: ______V

c) Stabilizer Installed Yes/No If Yes Make:

d) Current Drawin by the machine _____A Specify under test run.

e) Temperature Reading

b) Electrical supply input Volts________V

If more than 3V,

please consult

electrician for

proper earthing

to the unit.

Return Temperature

C

Supply Temperature

C

Difference C

Difference should be

more than 12 Degree C

Has the Indoor Unit been placed with slope towards

drain end. If yes, mention angle of slope.

Note: Water to be poured in drain Pan & proper

draining from drain pipe to be checked.

Yes/No

Yes/No

Customer Remarks / Signature:

Service center stamp

Installer Sign

Room Dimensions:

Yes/No

Yes/No

Yes/No

Yes/No

Yes/No

Yes/No

Yes/No

______Gms

Yes/No

Yes/No

Length-

Width-

Height-

NOrth/South/East/West

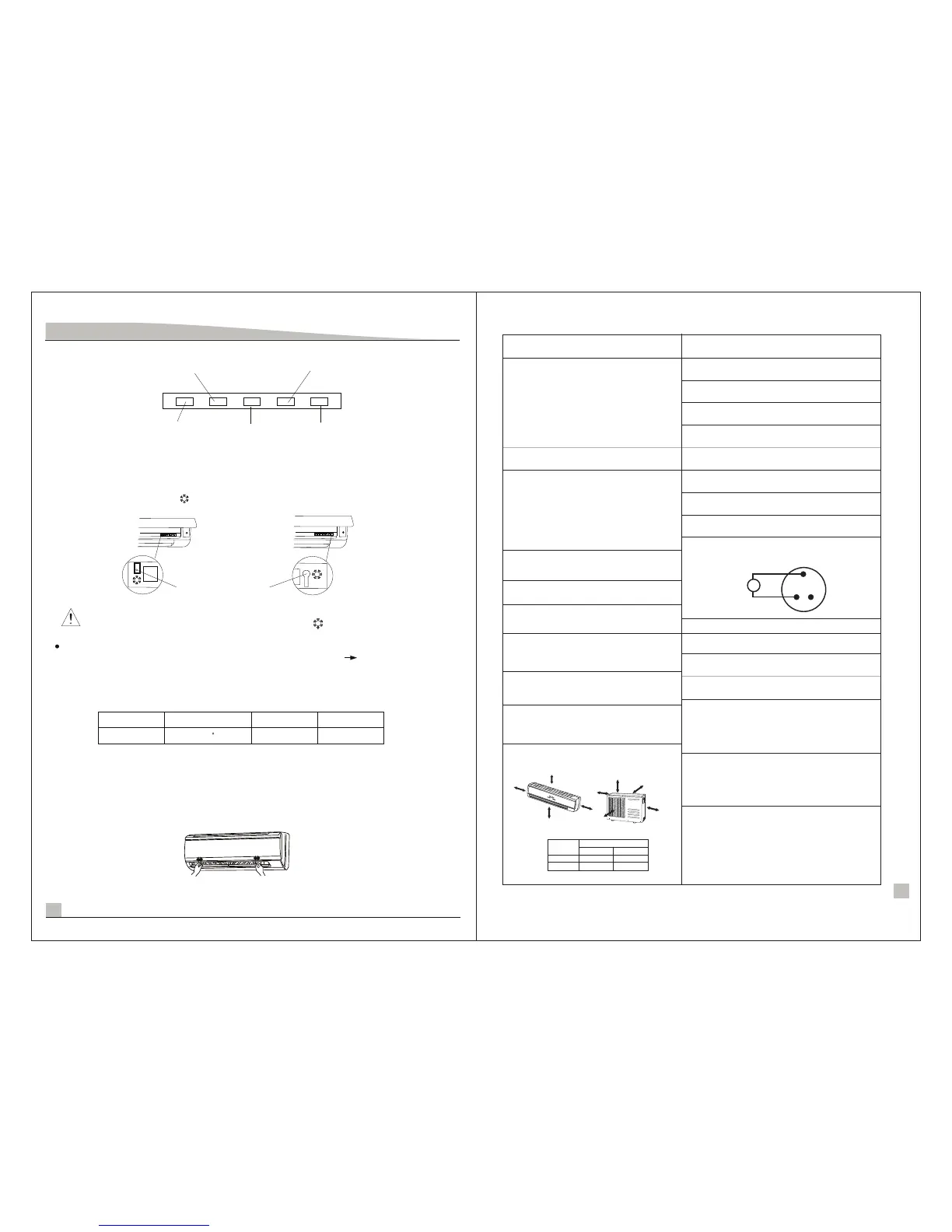

8. Installation of the Unit as per below distance spec.

9. All flarinng has to be done as per the Installation Manual

Address:

Contact Number:

Installation

1.Is the Capacity of the machine

suitable for the room in which

machine is installed

2. Is the strength of installation enough.

Is the machine installed securely on installation plate

3. Direction of condenser of

machine is towards

4. If the direction of the condenser is towards south

or west proper shade provided to the machine

5. Specify piping length

Horizontal & Vertical Distance

between IDU & ODU

H _____ m

_____ m

V _____ m

6. Has the IDU been placed below ODU

If yes, have U traps been provided at

every 5m.

7. Has gas charging been done

for extra length of Piping

Grade

Clearance (cm)

7K-28K

A

B

30K- 38K

10

30

5

12

More than 70cm

More than 10cm

More than 60cm

More than 10cm

More than 60cm

More than “A”

More than “B”

More than “B”

More than 2.3m

To be filled by Person of Service Center

Loading...

Loading...