4.3 Vitocal 300-G/350-G with one heating circuit without mixer, one heating circuit with

mixer, DHW heating, heating water buffer cylinder and active cooling function via AC-Box

(2-pipe version), with fan convector

ID: 4605351_1304_03

Application range

Detached house with two heating circuits with different design layouts.

Size DHW cylinder

wP

in accordance with current standards and

requirements. Cooling via a separate cooling circuit e.g. in conjunction

with fan convectors

rE

.

Main components

■ Vitocal 300-G/350-G, type BW or BWC, up to 17 kW

■ Vitotronic 200, type WO1B

■ DHW cylinder

■ Heating water buffer cylinder

■ AC-Box

Heating water buffer cylinder

The minimum flow rate of heat pump

1

is safeguarded via heating

water buffer cylinder

eP

and secondary pump

6

. It is possible to use

differential pressure-dependent heating circuit pumps

tT

and

zE

.

Central heating by heat pump

Heat pump

1

, primary pump

5

and secondary pump

6

start when

the actual temperature captured by cylinder temperature sensor

eQ

of

heating water buffer cylinder

eP

falls below the set temperature selec-

ted at control unit

2

.

Control unit

2

regulates the heating water flow temperature. Subject

to demand, secondary pump

6

delivers heating water via heating

water buffer cylinder

eP

to the heating circuit, or via circulation pump

for cylinder heating

7

to DHW cylinder

wP

.

Type BWC:

Subject to demand, integral secondary pump

6

or circulation pump

for cylinder heating

7

delivers heating water either to the heating cir-

cuits or DHW cylinder

wP

.

Heating circuit pumps tT and zE deliver the required water volume to

the heating circuits. The flow rate in the heating circuit is regulated by

opening or closing the thermostatic radiator valves or the valves of the

underfloor heating distributor.

To balance the difference in energy between the primary and secon-

dary circuits, operate heating water buffer cylinder

eP

. Any heat not

absorbed by the heating circuits is stored in heating water buffer cyl-

inder

eP

. In addition, heat pump

1

achieves longer runtimes, and the

heating circuits are supplied with heat from heating water buffer cylin-

der

eP

during power-OFF periods.

DHW heating by heat pump

In the delivered condition, DHW heating by heat pump

1

is given

priority over the heating circuits and takes precedence at night.

The heat demand is issued via cylinder temperature sensor

wQ

and

control unit

2

, which controls circulation pump for cylinder heating

7

. The control unit raises the flow temperature to the value required

for DHW heating.

Type BWC:

The heat demand is issued via cylinder temperature sensor

wQ

and

control unit

2

, which controls integral circulation pump for cylinder

heating

7

.

The flow temperature can be raised above 60 °C with instantaneous

heating water heater

4

.

Active cooling function via AC-Box

The building can be cooled with heat pump control unit

2

in conjunc-

tion with AC-Box

qZ

(accessories). The natural cooling function is

enabled by control unit

2

for the cooling circuit as soon as the thresh-

old temperature (cooling limit temperature) that can be selected at

control unit

2

is exceeded. The valves in the AC-Box are set to natural

cooling. Heat is extracted from the cooling circuit and transferred to

the ground. If the cooling capacity is insufficient, the internal valves in

the AC-Box are set to active cooling and heat pump

1

starts. This

causes heat to be extracted from cooling circuit

rP

, and transferred

via heat pump

1

to consumer groups

wP

,

eP

,

tP

and

zP

. If there is

no consumer demand, the heat is transferred to the ground via probe

qW

.

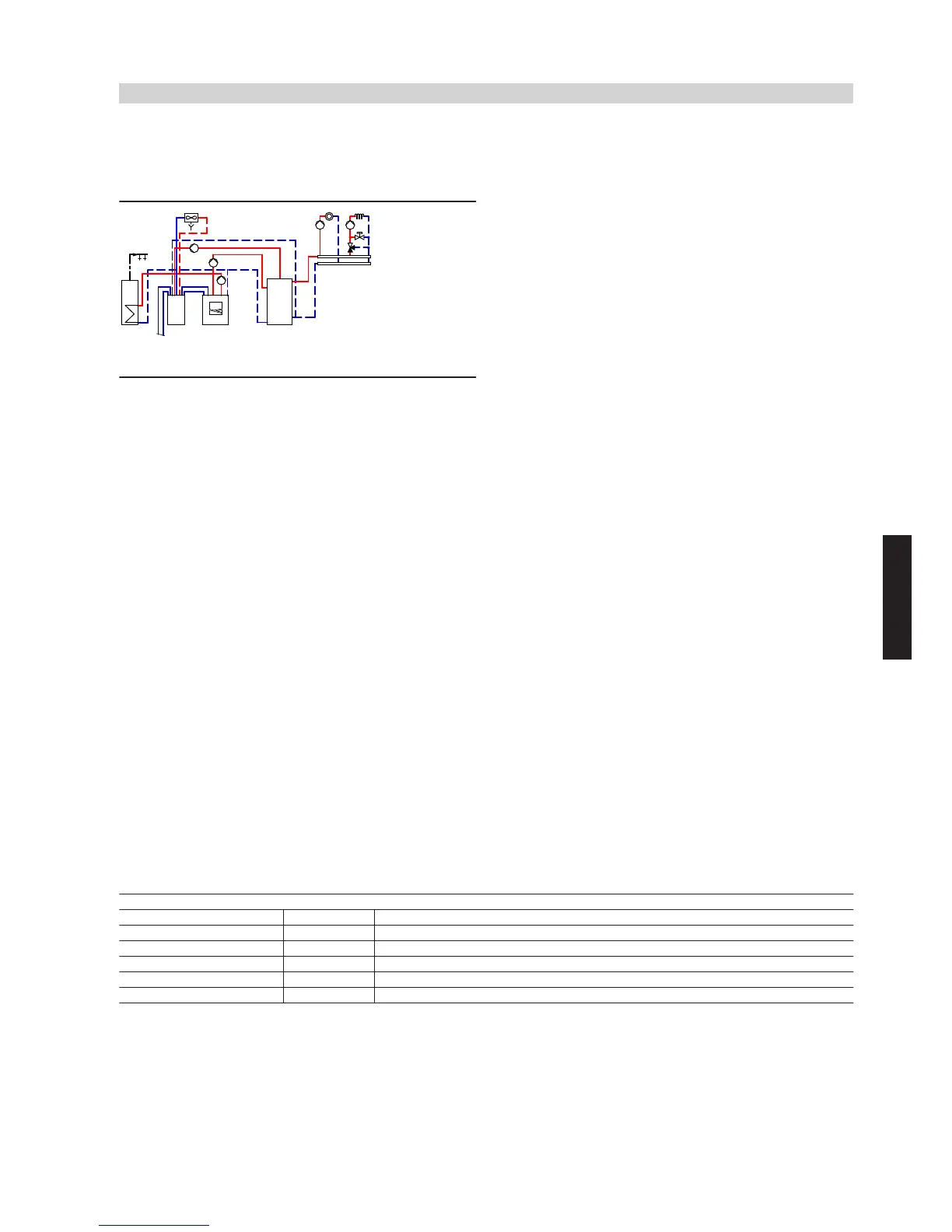

Required parameter settings

ID: 4605351_1304_03

Parameter Value Function

7000 6 With heating circuit A1/HC1, M2/HC2, DHW cylinder

7100 3 Active cooling

7101 4 Cooling via separate cooling circuit

7104 50 Influence room temperature hook-up cooling circuit

7111 4 Cooling curve slope

Vitocal 300-G/350-G

(cont.)

System examples

VIESMANN

81

5822 472 GB

4

Loading...

Loading...