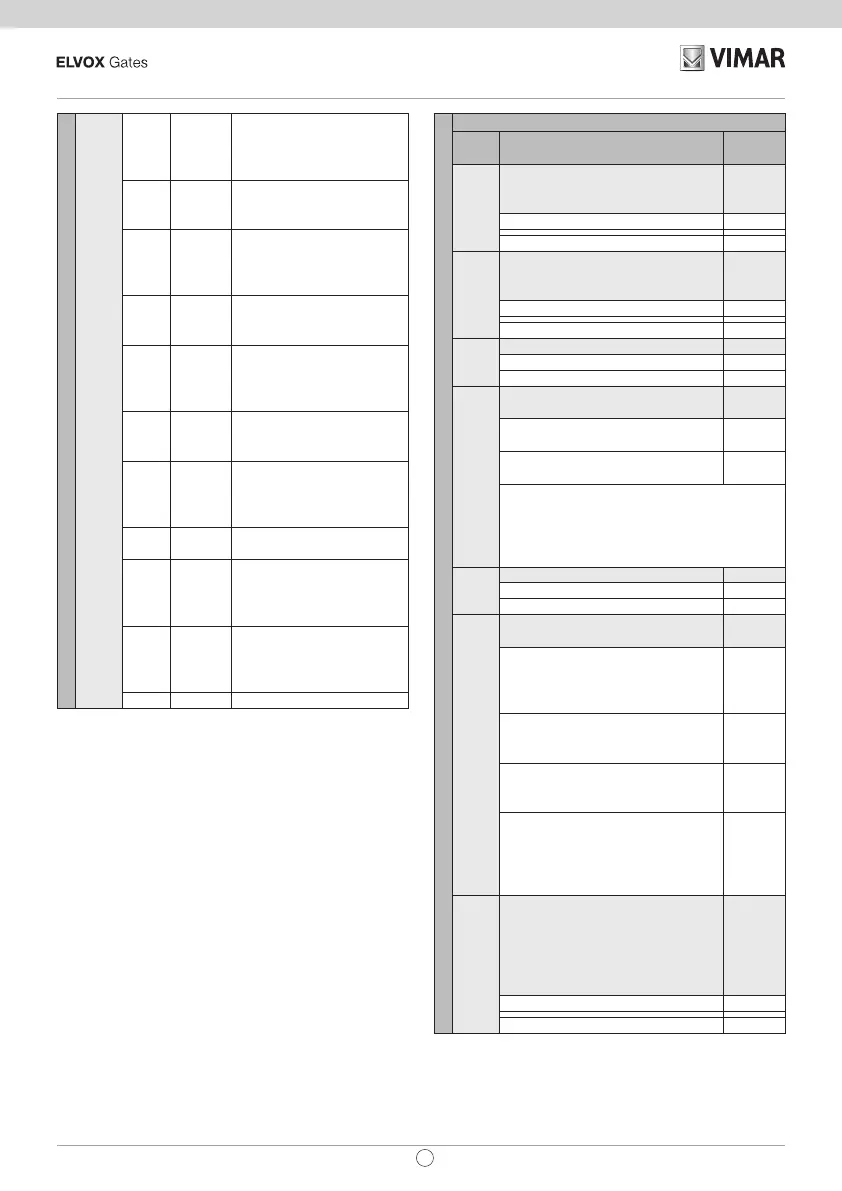

17

SW24.W

LRNT

LRNA

PP OP 2 Start opening motor 2

When button pressed:

slowdown start position on

opening setting.

PP OP 2 When button pressed end

of travel position setting or

continuation to the stop.

PP CL 2 Start closing motor 2 When

button pressed: slowdown

start position on closing

setting.

- CL 2 Continuation of motor 2

closing at slowdown speed

up to stop.

PP CL 1 Start closing motor 1 When

button pressed: slowdown

start position on closing

setting.

- CL 1 Continuation of motor 1

closing at slowdown speed

up to stop.

OPED Start pedestrian opening.

When button pressed:

pedestrian opening posi-

tion setting

- CPED Leaf closing from pedes-

trian opening position

PP DLOP Start opening. When

the oset time setting in

opening button is pressed,

motor 2 starts.

PP DLCL Start closing. When the o-

set time setting in closing

button is pressed, motor

1 starts.

- END End of procedure

Self-calibration:

If the gate travel parameter is changed, there is no need

for the installer to run new calibrations, however, when

changing the travel parameters, the control panel needs

to learn the current curve again, thus disabling the obsta-

cle detection only during the self-calibration manoeuvre.

Self-calibration is appropriately signalled:

- on the control panel display by the code AT

- by the light ashing at twice the normal frequency

The events generating self-calibration are:

- change in parameters: T24, T25, T26, T27, T28, T29,

T30, T31, T32, T33, T34, T35, T40, T41

- loading of settings from a MEM.W memory card

- reset/import of settings from the Wi-Gate app

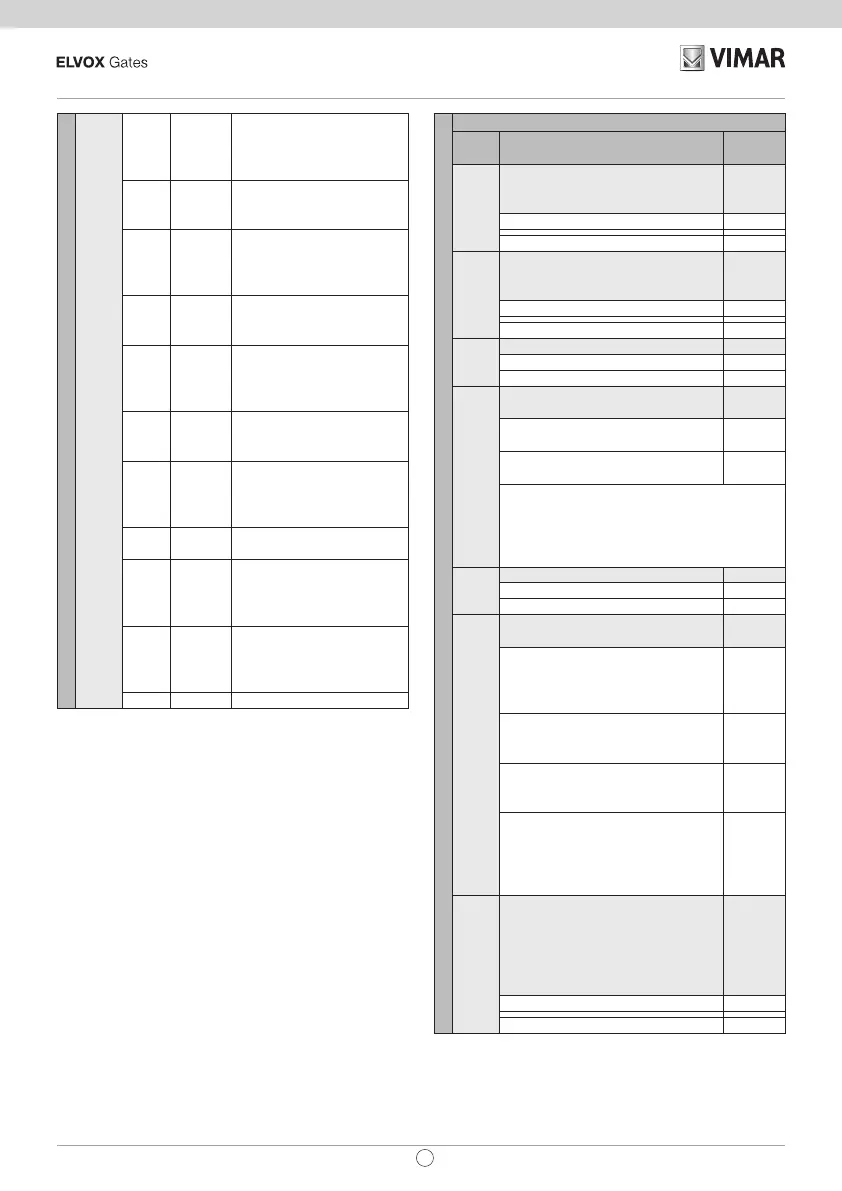

TRV

Gate travel parameters

Sub

menu

Description Values

(default)

T1

Motor 1 force (%).

Sets the value of the force given to

the motor to push the leaf

(50)

Minimum force 1

Maximum force 100

T2

Motor 2 force (%).

Sets the value of the force given to

the motor to push the leaf

(50)

Minimum force 1

Maximum force 100

T3

First leaf to move (M1)

Motor 1 M1

Motor 2 M2

T4

Direction.

Sets the motor direction

(1)

Standard (a linear motor closes the

gate with pistons extended)

1

Inverse (a linear motor closes the

gate with pistons retracted)

2

Note:

Inverts both motors. If only one motor has

an incorrect direction, invert the power

supply wires on the motor with the incorrect

direction.

T6

Number of motors (2)

Single-leaf gate 1

2 leaf gate 2

T7

Choice of intervention method

for obstacle detection

(1)

Overcurrent or leaf stopped:

the obstacle is detected when the

current threshold or the encoder

slowdown threshold is exceeded

1

Leaf stopped: the obstacle is

detected only when the leaf slows

down excessively

2

Overcurrent: the obstacle is de-

tected when the current threshold

is exceeded

3

Overcurrent and leaf stopped:

the obstacle is detected when the

current threshold and the encoder

slowdown threshold are exceeded

at the same time

4

T10

Obstacle detection time motor 1

Time after which the current

threshold or the encoder threshold

trigger the obstacle detection for

motor 1 (adjustable at intervals of

100 ms)

(20)

100 ms (minimum time)

10

600 ms (maximum time) 60

EN

Loading...

Loading...