7602026

25

11) FINAL TESTING

Supply power to the system and perform the

following functional checks:

- Load test:

- Load the lift with 1.1 times the rated load stated on

the nameplate.

- Send the lift up and down several times, checking its

stability on the rail.

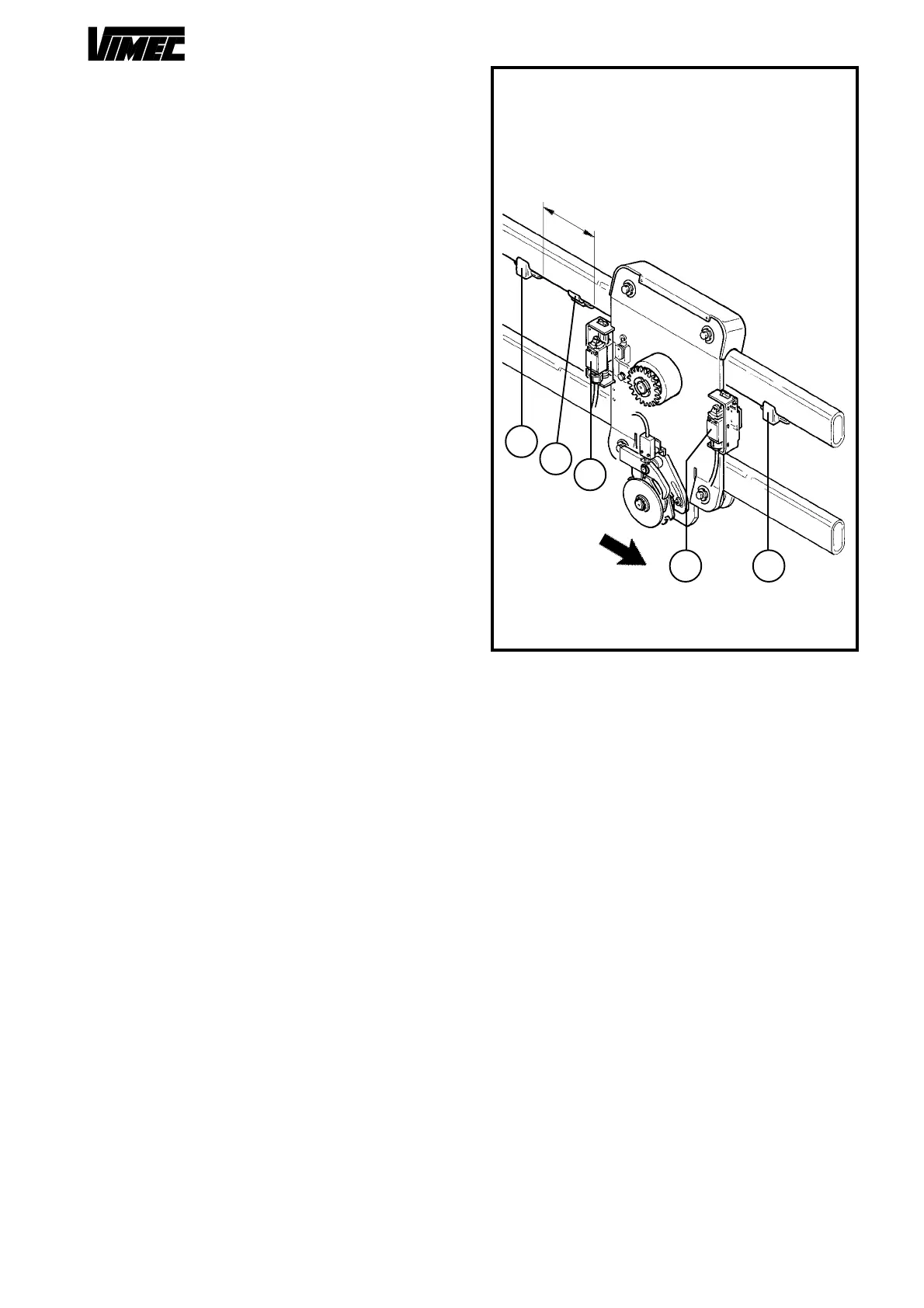

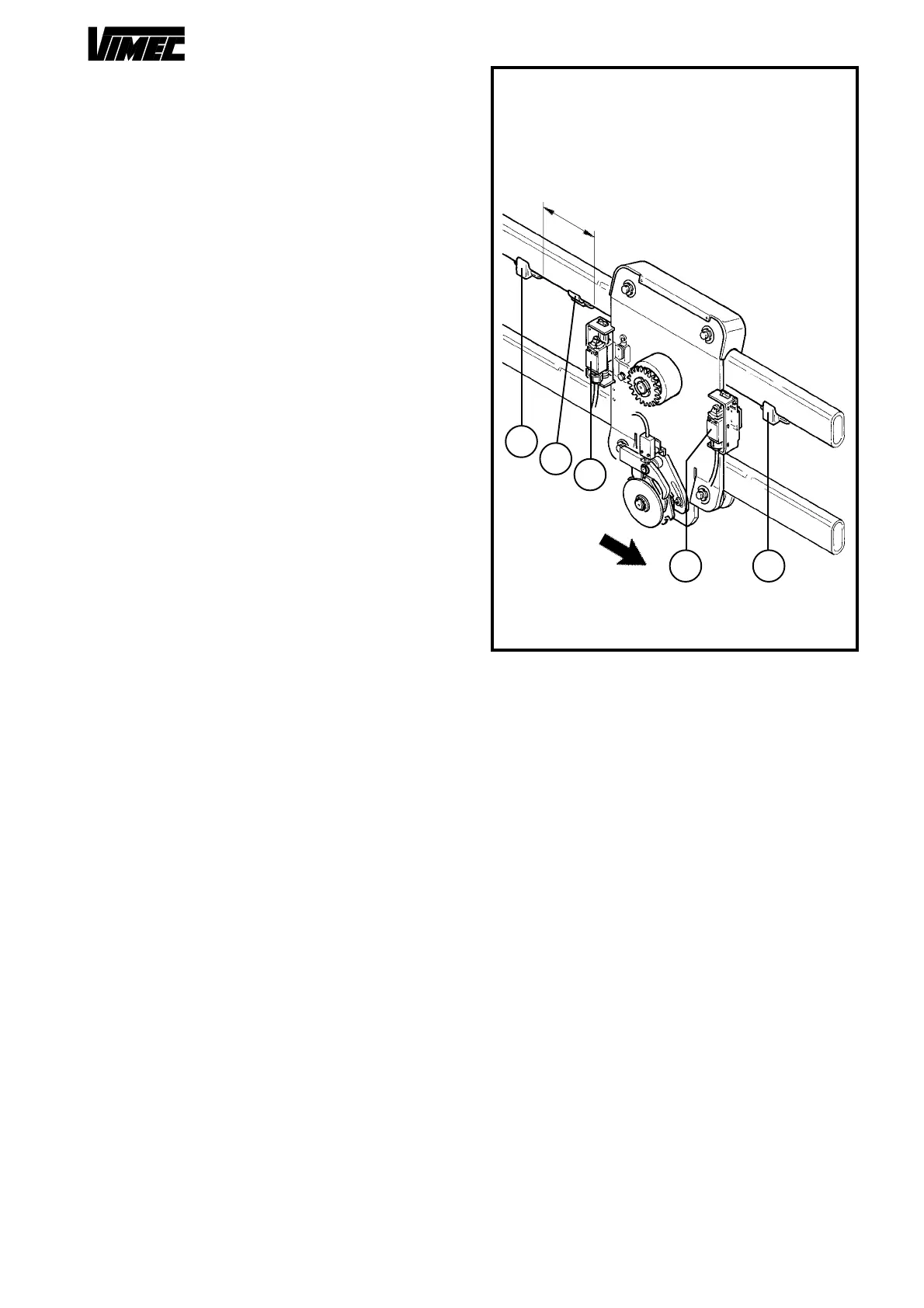

- Drive the machine to the upper level and place the

platform as to let the unloading of the bodywork and

assemble the cam on the guide (Fig. 33/a), so that the

rise limitstop micro is pressed on (Fig. 33/b).

- Drive the machine to the lower level and place the

platform as to let the unloading of the bodywork and

assemble the cam on the guide (Fig. 33/c),so that the

descent limitstop micro operates (Fig. 33/d).

- Repeat the operation to check the operating of the

limit stop and extra stroke micro, making the machine

rise and descent.

-Lock the cams with the indicated cylindrical pin Ø4x30.

- Place the third cam (mechanical extra stroke) with

the indicated cylindrical pin Ø4x30, on the guide decent

side paying attention to assemble it rotated 180° (Fig.

33/e).

- Preliminary checks

Perform the checks described in point 6.1 on page 8 of

the Use and Maintenance Manual.

- Safety gear test

Test the safety gear as described in Section 9, point

d.

(This test must be carried out with no load on the lift).

- Check on fixing of the rail

- Check that the rail is positioned in accordance with

the dimensions stated in the installation drawing (or

system layout) supplied with the lift.

- Check that all the fixing screws of the connections to

the mounts or any expansion plugs are stable and firmly

tightened.

FIG.33

SN CARRIAGE CONFIGURATION

FRONT VIEW

M

A

C

H

I

N

E

A

D

V

A

N

C

E

R

I

S

E

S

I

D

E

D

E

S

C

E

N

T

S

I

D

E

a

e

~

1

3

0

c

d

a

Loading...

Loading...