Service and maintenance

Central lubrication 165

Lubricant recommendation

The system requires that the lubricant is clean and can be pumped

at the ambient temperature. Therefore, use lubricants of

recommended NLGI grease class. Lower grease grade may result

in reduced lubrication performance and increased wear.

Q Do not mix different types of lubricant. Change all lubricant, not

only in the reservoir.

Q No graphite or Teflon additives are permitted in the lubricant.

Q Use of molybdenum disulphide (MoS

2

) is only allowed if:

– the lubricant is of very high quality and does not contain

more than 5% MoS

2

.

– the lubrication system is checked at regular intervals for

reliable function.

– the main lines are flushed at least once a year.

NOTE! Special tools are needed to troubleshoot, adjust, and

repair the control unit. Therefore, contact qualified service

personnel when needed.

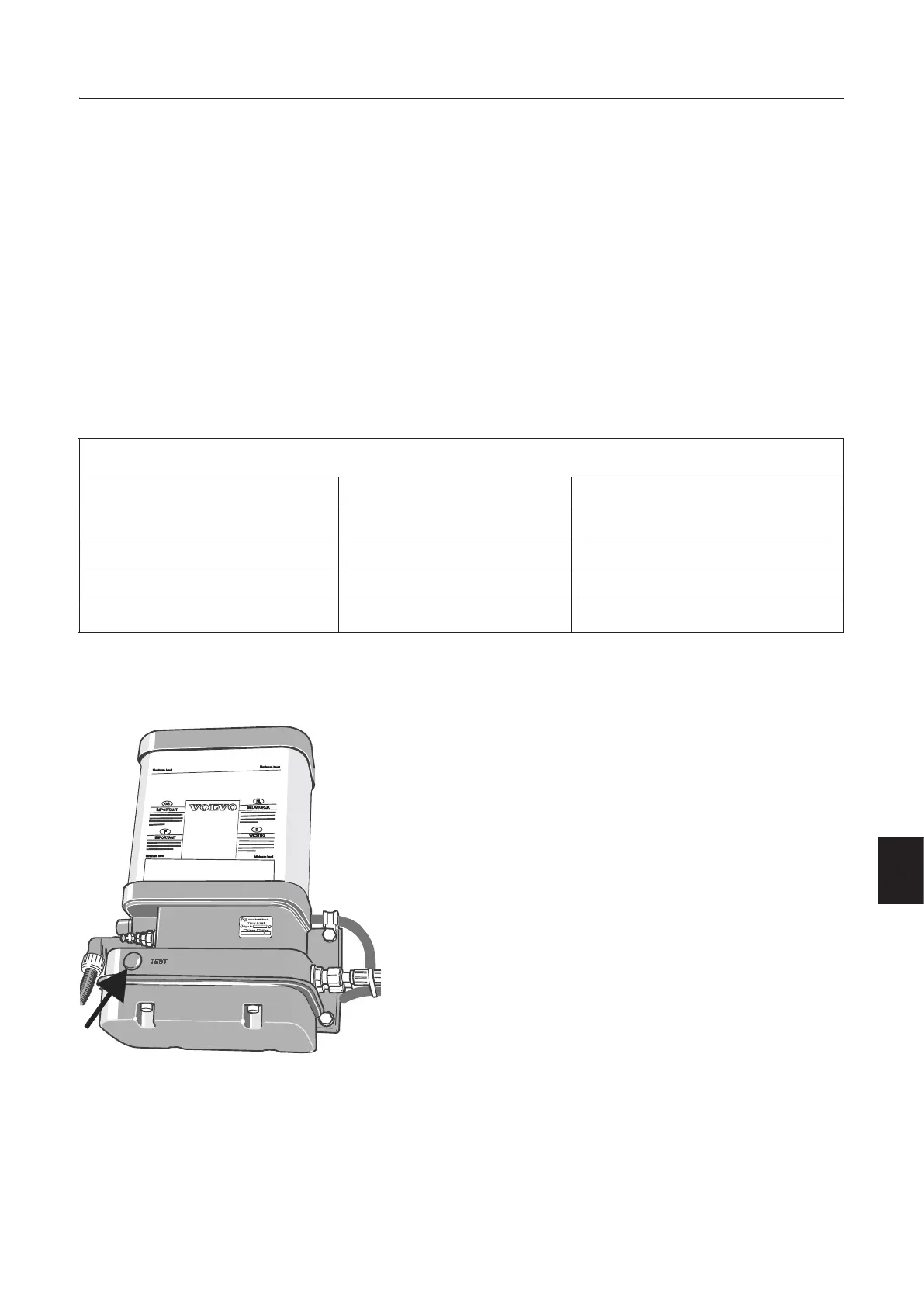

System test

A system test can be performed to check the lubrication system's

function or to get extra lubrication, e.g., after washing.The test

button used to start a system test is located on the front of the

pump.

A test cycle can only be run when the pump is between two normal

lubrication cycles (not when lubrication cycle is in progress).

Single lubrication test cycle

The pump only runs one lubrication cycle via one main line. Can

be used after washing to get extra lubrication.

1 Turn the ignition key to position 1 (operating position).

2 Press in the test button for 2–6 seconds.

3 The lubrication cycle starts.

4 The test cycle finishes automatically.

If the lubrication test cycle has been used to get extra

lubrication after washing, the test button should be pressed

in one more time to lubricate the other main line.

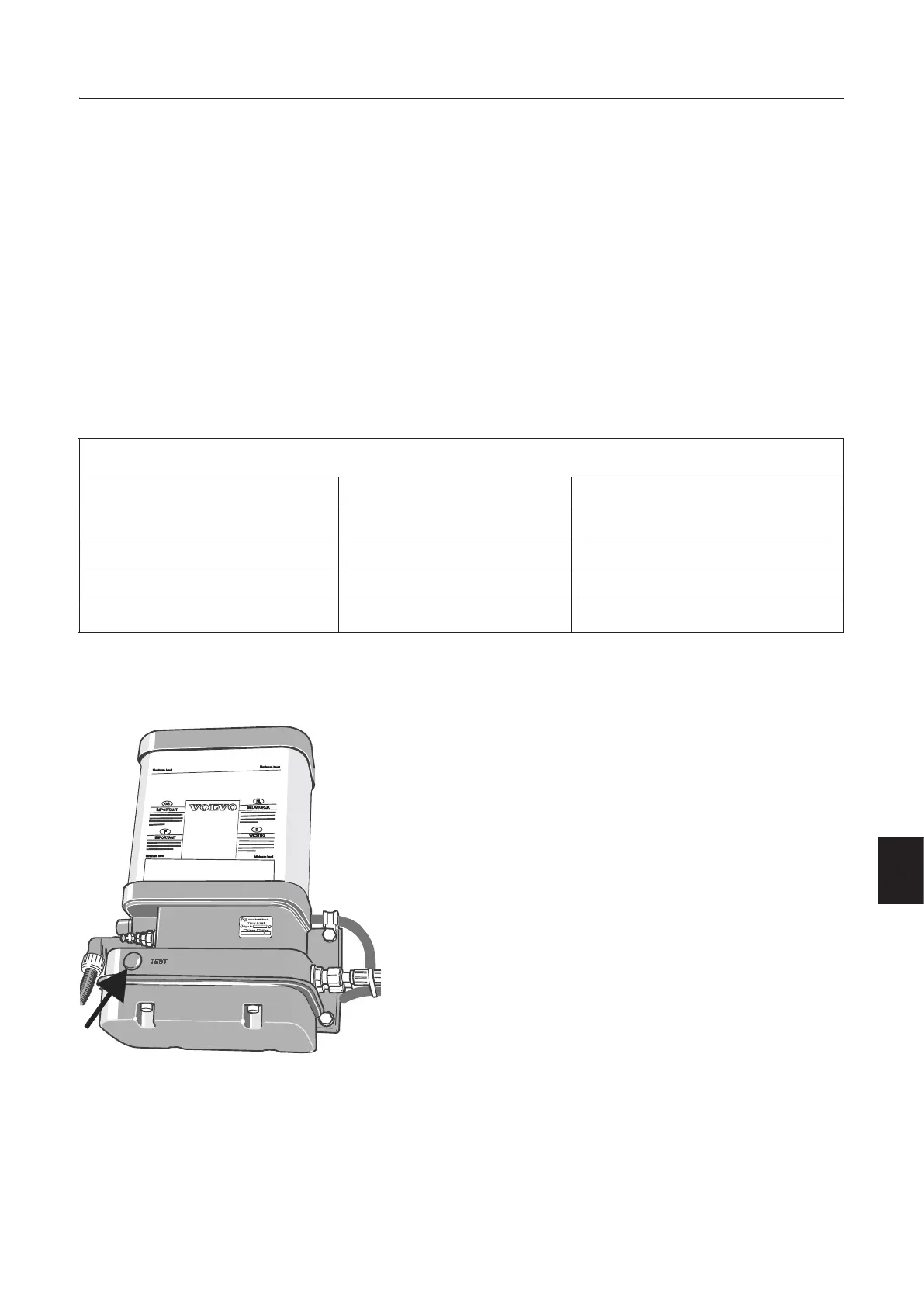

Lubricant recommendation

Lowest temperature Highest temperature Lubricant type, NLGI

Above -25 °C (-13 °F) +80°C (176 °F) 2

Below -25 °C (-13 °F) 0 °C (32 °F) 0 / 1

Below -25 °C (-13 °F) +80 °C (176 °F) Synthetic 2

Below -25 °C (-13 °F) 0 °C (32 °F) Synthetic 0 / 1

1041514

Test button

Loading...

Loading...