CAUTION!

The chart obtains only for metallic housings.

For nylon housings the VOSS V-thread

has to be used.

Screw-in thread Nominal size Fir-tree for tubes

NS O.D. x wall thickness

M 16 x 1.5 8 6 x 1

8 x 1/9 x 1.5

10 x 1,25

10 x 1/11 x 1.5

12 x 1.5

M 22 x 1.5 12 6 x 1

8 x 1/9 x 1.5

10 x 1.25

10 x 1/11 x 1.5

12 x 1.5/14 x 2.5

12,5 x 1.25/14 x 2

16 x 2

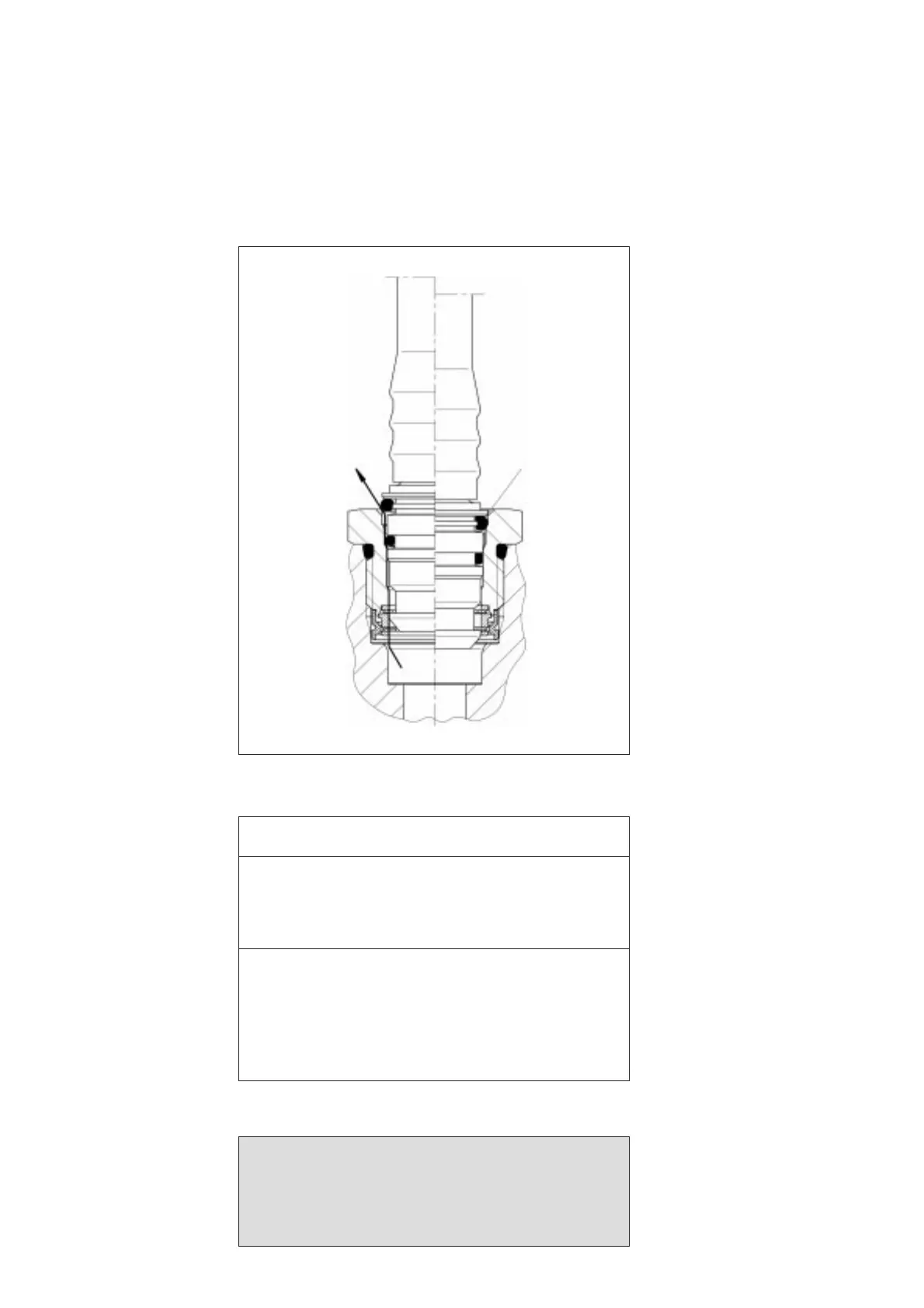

VOSS quick connect system 232, functional diagram

Retention of the plug in the

first snap-in stage thus solves

the safety problem of faulty

insertion, leading to sudden

failure of the connection and

subsequent breakdown of the

entire system. Compensation

for the minor leakage is

topped up by the compressor.

3.4 Product range

The VOSS quick connect

system is available in nominal

sizes 8 and 12.

Please refer to the table below

for possible combinations of

plug size and nylon tubing

dimensions.

The entire range of parts and

accessories for the VOSS

quick connect system 232 is

contained in catalogue 232.

3.3 Functional description

The coupling element forms

the connection to the compo-

nent. Connection is made by

screwing the coupling element

into an appropriate port.

Suitable ports are the industri-

ally standard moulded port for

the VOSS quick connect sys-

tem 230 and special port

shapes agreed with VOSS for

the application in question.

On request, we will be

pleased to supply design

specifications for the appropri-

ate port.

The connection between a

nylon tube and a component

is made by sliding the plug

into the coupling element.

When this is done the plug is

kept in place by a two-stage

retaining element which, once

it has reached its second

snap-in location, is automati-

cally shifted from the push-in

to the locking position by

means of axial compression

and the pressure of the com-

pressed air.

Should the second snap-in

stage not be reached due to

insufficient insertion force or

other unfavourable circum-

stances, the plug is safe from

disconnection as soon as the

retaining element has snap-

ped into the first stage.

It is possible to push the

retaining element into this first

snap-in stage by applying very

little force. In this retention

position, the connection has

an intended leakage path.

Incomplete connections may

be noticed by an acoustic

warning signal and a drop in

pressure.

4

Possible combinations

of thread size, nominal size and tube dimensions

First snap-in

stage

Second snap-in

stage

Axial

compression

Acoustic warning

signal through

leakage path

Loading...

Loading...