Householder Information

IMPORTANT!

Your boiler must be commissioned in order to:

- Validate your warranty

- Ensure the boiler has been installed correctly and avoid premature failure

- Set the boiler to its optimum efficiency. Operating conditions for the boiler will vary from site to site, your

commissioning engineer has specialised equipment to check the oil pressure and analyse the exhaust gases for

temperature, smoke and carbon dioxide content.

Your installer will organise the commissioning of your boiler. Should you experience any difficulty locating an

engineer, our service department may be able to provide you with details of an engineer in your area.

“Benchmark” Installation, Commissioning and Service Record Log Book

Please ensure that your installer has completed all sections of the log book (found at the back of this manual).

The log book will be required in the event of any warranty work. Ensure that the service record is completed.

Warranty

Your HRM boiler is under warranty for 2 years from the date of installation.

Warranty Conditions

- The boiler must be installed and commissioned in accordance with our handbook

- The boiler must not be repaired, modified or tampered with by any person not authorised by HRM

Extended Warranty

The “Benchmark” and warranty registration document at the end of this manual should be completed as

appropriate by your installer / engineer. This is your record that the boiler has been correctly installed in accordance

with our recommendations. Return the warranty registration document to HRM in order to qualify for a further 3 year

warranty of the heat exchanger – a total of 5 years.

Extended Warranty Conditions

- The boiler must be serviced annually and maintained in accordance with this handbook. The

“Benchmark” service log is located at the back of this manual

- This warranty is in addition to your statutory and other legal rights

After Sales Service

- If your boiler fails during the warranty period contact your installer, who will be able to identify the

cause of the problem. If appropriate, your installer will contact us.

- Under no circumstances should “in warranty” work be undertaken without authorisation from the HRM

service department

- If you are unable to contact your installer please contact our service department. Quoting your boiler’s

serial number when phoning – this can be found on the cover of this manual.

Standard X-ternal & System X-ternal

Handbook

Householder Information

IMPORTANT!

Your boiler must be commissioned in order to:

- Validate your warranty

- Ensure the boiler has been installed correctly and avoid premature failure

- Set the boiler to its optimum efficiency. Operating conditions for the boiler will vary from site to site, your

commissioning engineer has specialised equipment to check the oil pressure and analyse the exhaust gases for

temperature, smoke and carbon dioxide content.

Your installer will organise the commissioning of your boiler. Should you experience any difficulty locating an

engineer, our service department may be able to provide you with details of an engineer in your area.

“Benchmark” Installation, Commissioning and Service Record Log Book

Please ensure that your installer has completed all sections of the log book (found at the back of this manual).

The log book will be required in the event of any warranty work. Ensure that the service record is completed.

Warranty

Your HRM boiler is under warranty for 2 years from the date of installation.

Warranty Conditions

- The boiler must be installed and commissioned in accordance with our handbook

- The boiler must not be repaired, modified or tampered with by any person not authorised by HRM

Extended Warranty

The “Benchmark” and warranty registration document at the end of this manual should be completed as

appropriate by your installer / engineer. This is your record that the boiler has been correctly installed in accordance

with our recommendations. Return the warranty registration document to HRM in order to qualify for a further 3 year

warranty of the heat exchanger – a total of 5 years.

Extended Warranty Conditions

- The boiler must be serviced annually and maintained in accordance with this handbook. The

“Benchmark” service log is located at the back of this manual

- This warranty is in addition to your statutory and other legal rights

After Sales Service

- If your boiler fails during the warranty period contact your installer, who will be able to identify the

cause of the problem. If appropriate, your installer will contact us.

- Under no circumstances should “in warranty” work be undertaken without authorisation from the HRM

service department

- If you are unable to contact your installer please contact our service department. Quoting your boiler’s

serial number when phoning – this can be found on the cover of this manual.

Standard X-ternal & System X-ternal

Handbook

Contents Page

DESCRIPTION PAGE

Householder Information

Warranty Registration Document End Of Manual

Warranty 3

Extended Warranty 3

After Sales Service 3

Boiler Controls: Wallstar 4

System Wallstar 5

Wallstar Combi 6-7

Burner Lockout 8

Technical Specifications

Boiler Dimensions: Wallstar 9

Boiler Dimensions: System Wallstar 10

Boiler Dimensions: Wallstar Combi 11

Technical Specifications 12

Burner Settings 13

Boiler Installation

Regulations 14

Boiler Sizing 14

Refurbishing An Old System 14

System Protection 14

Boiler Location 15

Wall Construction 15

Flue Terminating Positions 16

Fuel Supply System 17

Oil Supply 17

Installation Procedure

Wallstar 18-23

System Wallstar 24-31

Wallstar Combi 32-40

Condensate Drain 41

Wiring Diagrams

Wallstar 42

System Wallstar 42

Wallstar Combi 43

Boiler Maintenance

Baffle Removal 44

Fault Diagnosis

Wallstar Combi 45

Wallstar Combi Components 46

Contacts

Tel No: 01953 455400

Fax No: 01953 454483

Email: info@hrmboilers.co.uk or technical@hrmboilers.co.uk

1

Standard Wallstar, System Wallstar &

Wallstar Combi Manual

Contents Page

DESCRIPTION PAGE

Householder Information

Warranty Registration Document End Of Manual

Warranty 3

Extended Warranty 3

After Sales Service 3

Boiler Controls: Wallstar 4

System Wallstar 5

Wallstar Combi 6-7

Burner Lockout 8

Technical Specifications

Boiler Dimensions: Wallstar 9

Boiler Dimensions: System Wallstar 10

Boiler Dimensions: Wallstar Combi 11

Technical Specifications 12

Burner Settings 13

Boiler Installation

Regulations 14

Boiler Sizing 14

Refurbishing An Old System 14

System Protection 14

Boiler Location 15

Wall Construction 15

Flue Terminating Positions 16

Fuel Supply System 17

Oil Supply 17

Installation Procedure

Wallstar 18-23

System Wallstar 24-31

Wallstar Combi 32-40

Condensate Drain 41

Wiring Diagrams

Wallstar 42

System Wallstar 42

Wallstar Combi 43

Boiler Maintenance

Baffle Removal 44

Fault Diagnosis

Wallstar Combi 45

Wallstar Combi Components 46

Contacts

Tel No: 01953 455400

Fax No: 01953 454483

Email: info@hrmboilers.co.uk or technical@hrmboilers.co.uk

1

Standard Wallstar, System Wallstar &

Wallstar Combi Manual

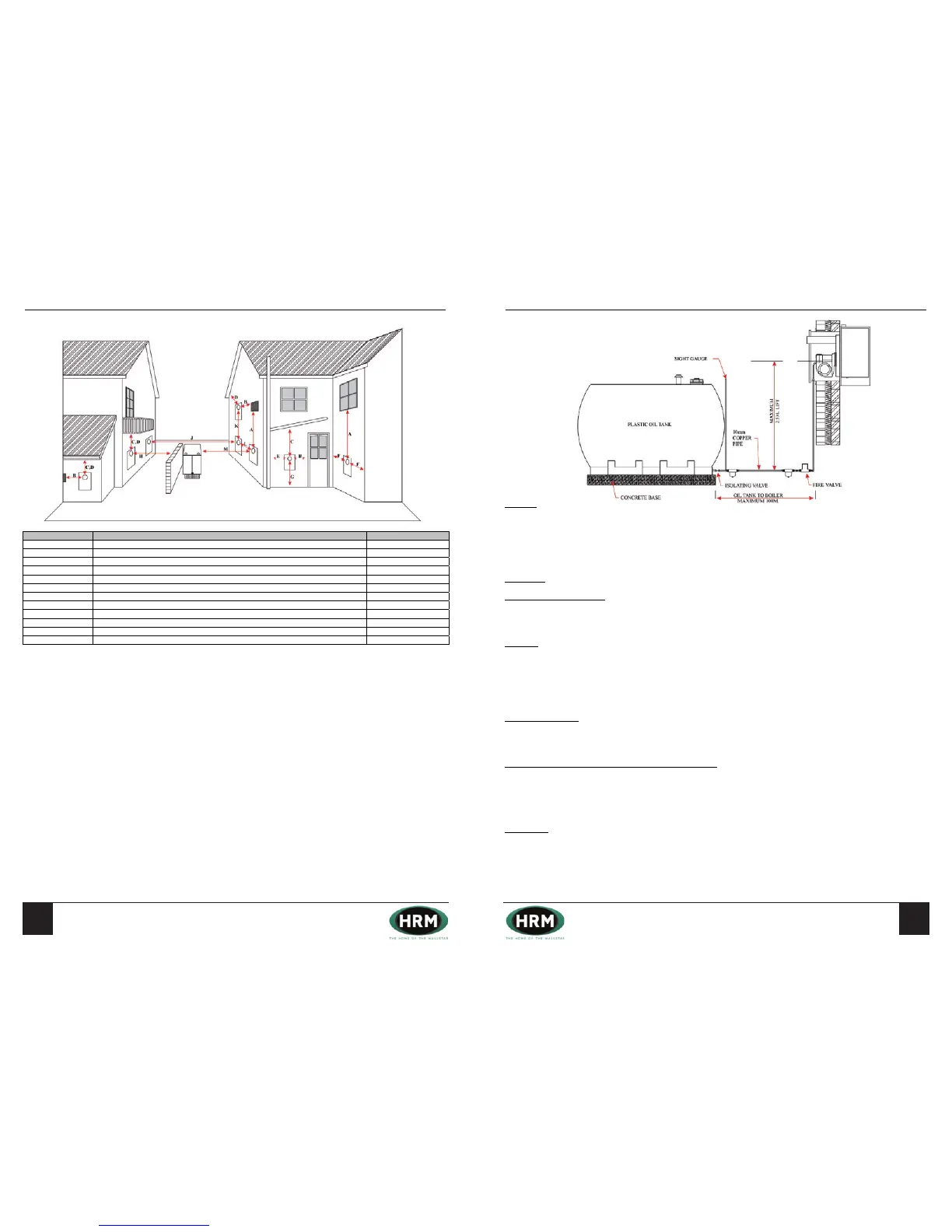

Flue Terminating Positions

Information taken from BS 5410-1:1997 and The Building Regulations: Approved Document J

Notes:

1 - Terminals should be positioned so as to avoid products of combustion accumulating in stagnant pockets around

the building or entering into buildings.

2 - Where a flue is terminated less than 600mm away from a projection above it and the projection consists of plastics

or has a combustible or painted surface, then a shield of at least 750mm should be fitted to protect these surfaces.

3 - If the lowest part of the terminal is less than 2m above the ground, balcony, flat roof or other place to which any

person has access, the terminal should be protected by a guard.

4 - Where a flue terminates near the boundry of an adjoining property, consideration should be given to possible noise

disturbance as some people are sensitive to even low noise levels.

5 - Boilers can produce sulphur deposits, occasionally these deposits are discharged out of the flue, this should be

taken into consideration when planning to site flues over patios etc.

Position Description Dimension

A Directly Below An Opening (Air Brick, Window, etc)

600mm

B Horizontally To An Opening

600mm

C Below a Gutter, Eaves or Balcony With Protection (Note 2)

75mm

D Below a Gutter, Eaves or Balcony Without Protection

600mm

E From Vertical Sanitary Pipework

300mm

F From An Internal or External Corner

300mm

G Above Ground or Balcony Level

300mm

H From Surface or Boundry Facing The Terminal

600mm

J From a Terminal Facing a Terminal

1200mm

K Vertical From a Terminal On The Same Wall

1500mm

L Horizontally From A Terminal On The Same Wall

750mm

M From An Oil Tank

1800mm

16

Standard Wallstar, System Wallstar &

Wallstar Combi Manual

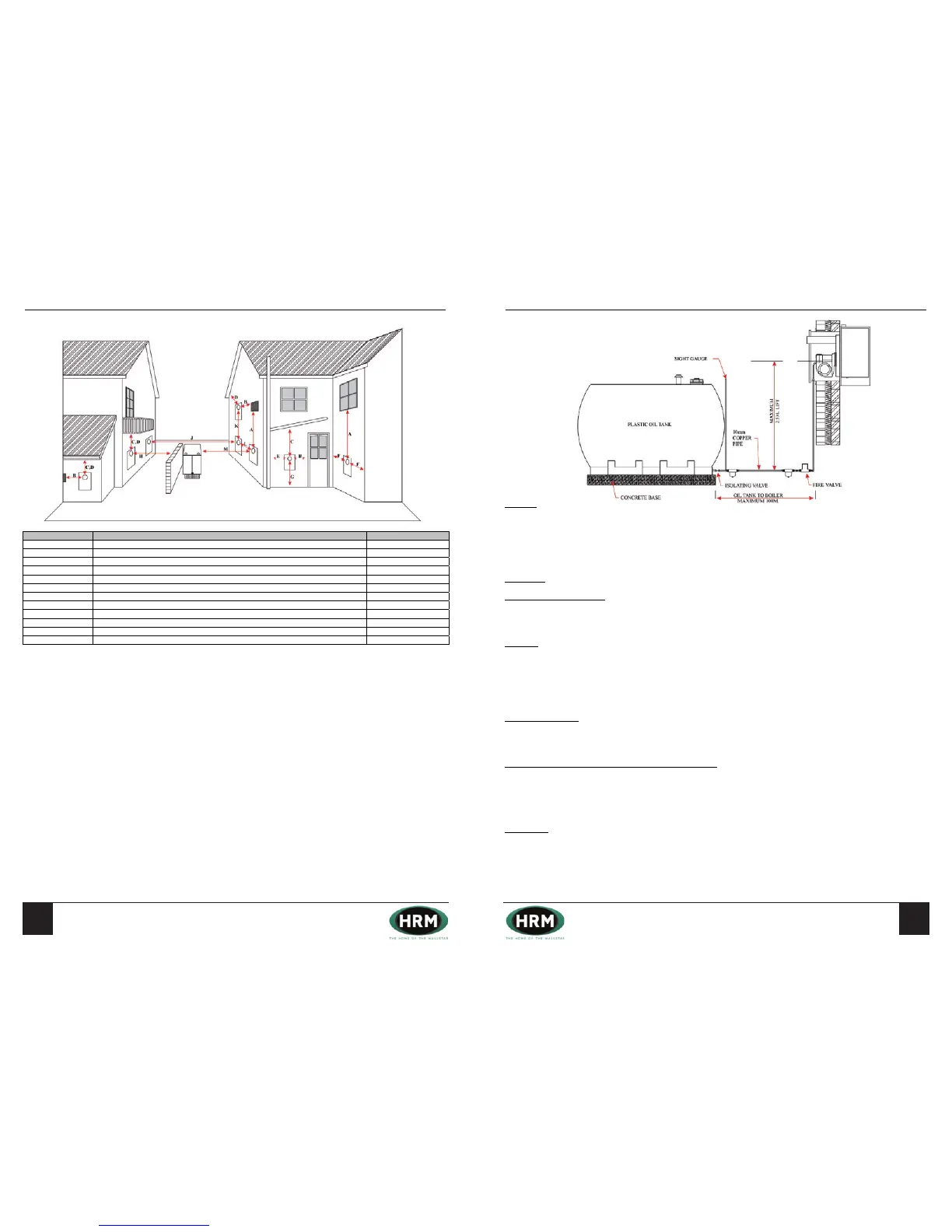

Fuel Supply System

Oil Tank

We recommend the use of plastic oil tanks, they require less maintenance than steel tanks and are longer lasting.

A bunded oil tank may be required on any environmentally sensitive site where spillage of oil could pollute rivers,

ponds, or any other water courses. Please refer to the appropriate requirements when locating oil tanks: “Control of

Pollution Regulations”, “Building Regulations” and OFTEC Technical Paper T19.

Oil Supply

Fuel Tank Below the Burner

The fuel pump can lift fuel to a height of 2.5m. A two pipe system or deaerator (Tiger Loop, 3K or similar) is not

required. For heights above 2.5m, please consult our technical department.

Pipework

Soldered fittings should not be used, as the joints will fail in the event of a fire. Flux deposits may damage the pump

and fuel may deteriorate the solder within the joint. Galvanised pipes and fittings must not be used. The aggressive

action of the fuel will erode the zinc and damage the fuel pump.

Keep the number of pipe joints to a minimum, form bends rather than using compression fittings.

Jointing Compounds

Jointing compounds should be used with care. Excessive amounts can cause blockages, and fragments may cause

failure of the fuel pump or the non-return valve. We recommend the use of a non-setting liquid pipe sealant.

Automatic Isolation of the Fuel Supply in the Event of a Fire

In accordance with Document J of the Building Regulations, we provide “a means of automatic isolation of

the fuel supply” in the form of a remote acting fire valve which must be fitted inline of the fuel supply in

accordance with BS 5410-1:1997. A clip is provided in the top of the wall duct for the fire valve capillary

bulb.

Oil Filtration

All boilers are supplied with flexible fuel lines with in line filter included. If the flexible fuel line needs replacing it must

be replaced by an item of this type (Part Number: BS099). A paper element filter is also supplied and must be fitted

adjacent to the boiler, replacement filters are available (Part Number: BS076). Where a steel oil tank is installed we

recommend a further paper element filter is also fitted adjacent to the oil tank.

17

Standard Wallstar, System Wallstar &

Wallstar Combi Manual

In accordance with Document J of the Building Regulations, “a means of automatic isolation of

the fuel supply” in the form of a remote acting re valve must be tted inline of the fuel supply in

accordance with BS 5410-1:1997. A clip is provided in the top of the wall duct for the re valve capillary

bulb.

All boilers are supplied with exible fuel line. If the exible fuel line needs replacing it must be replaced by an item of this

type (Part Number: BS012). A paper element lter is also supplied and must be tted adjacent to the boiler, replacement

lters are available (Part Number: BS076). Where a steel oil tank is installed we recommend a further paper element

lter is also tted adjacent to the oil tank.

Loading...

Loading...