Householder Information

IMPORTANT!

Your boiler must be commissioned in order to:

- Validate your warranty

- Ensure the boiler has been installed correctly and avoid premature failure

- Set the boiler to its optimum efficiency. Operating conditions for the boiler will vary from site to site, your

commissioning engineer has specialised equipment to check the oil pressure and analyse the exhaust gases for

temperature, smoke and carbon dioxide content.

Your installer will organise the commissioning of your boiler. Should you experience any difficulty locating an

engineer, our service department may be able to provide you with details of an engineer in your area.

“Benchmark” Installation, Commissioning and Service Record Log Book

Please ensure that your installer has completed all sections of the log book (found at the back of this manual).

The log book will be required in the event of any warranty work. Ensure that the service record is completed.

Warranty

Your HRM boiler is under warranty for 2 years from the date of installation.

Warranty Conditions

- The boiler must be installed and commissioned in accordance with our handbook

- The boiler must not be repaired, modified or tampered with by any person not authorised by HRM

Extended Warranty

The “Benchmark” and warranty registration document at the end of this manual should be completed as

appropriate by your installer / engineer. This is your record that the boiler has been correctly installed in accordance

with our recommendations. Return the warranty registration document to HRM in order to qualify for a further 3 year

warranty of the heat exchanger – a total of 5 years.

Extended Warranty Conditions

- The boiler must be serviced annually and maintained in accordance with this handbook. The

“Benchmark” service log is located at the back of this manual

- This warranty is in addition to your statutory and other legal rights

After Sales Service

- If your boiler fails during the warranty period contact your installer, who will be able to identify the

cause of the problem. If appropriate, your installer will contact us.

- Under no circumstances should “in warranty” work be undertaken without authorisation from the HRM

service department

- If you are unable to contact your installer please contact our service department. Quoting your boiler’s

serial number when phoning – this can be found on the cover of this manual.

Standard X-ternal & System X-ternal

Handbook

Householder Information

IMPORTANT!

Your boiler must be commissioned in order to:

- Validate your warranty

- Ensure the boiler has been installed correctly and avoid premature failure

- Set the boiler to its optimum efficiency. Operating conditions for the boiler will vary from site to site, your

commissioning engineer has specialised equipment to check the oil pressure and analyse the exhaust gases for

temperature, smoke and carbon dioxide content.

Your installer will organise the commissioning of your boiler. Should you experience any difficulty locating an

engineer, our service department may be able to provide you with details of an engineer in your area.

“Benchmark” Installation, Commissioning and Service Record Log Book

Please ensure that your installer has completed all sections of the log book (found at the back of this manual).

The log book will be required in the event of any warranty work. Ensure that the service record is completed.

Warranty

Your HRM boiler is under warranty for 2 years from the date of installation.

Warranty Conditions

- The boiler must be installed and commissioned in accordance with our handbook

- The boiler must not be repaired, modified or tampered with by any person not authorised by HRM

Extended Warranty

The “Benchmark” and warranty registration document at the end of this manual should be completed as

appropriate by your installer / engineer. This is your record that the boiler has been correctly installed in accordance

with our recommendations. Return the warranty registration document to HRM in order to qualify for a further 3 year

warranty of the heat exchanger – a total of 5 years.

Extended Warranty Conditions

- The boiler must be serviced annually and maintained in accordance with this handbook. The

“Benchmark” service log is located at the back of this manual

- This warranty is in addition to your statutory and other legal rights

After Sales Service

- If your boiler fails during the warranty period contact your installer, who will be able to identify the

cause of the problem. If appropriate, your installer will contact us.

- Under no circumstances should “in warranty” work be undertaken without authorisation from the HRM

service department

- If you are unable to contact your installer please contact our service department. Quoting your boiler’s

serial number when phoning – this can be found on the cover of this manual.

Standard X-ternal & System X-ternal

Handbook

Contents Page

DESCRIPTION PAGE

Householder Information

Warranty Registration Document End Of Manual

Warranty 3

Extended Warranty 3

After Sales Service 3

Boiler Controls: Wallstar 4

System Wallstar 5

Wallstar Combi 6-7

Burner Lockout 8

Technical Specifications

Boiler Dimensions: Wallstar 9

Boiler Dimensions: System Wallstar 10

Boiler Dimensions: Wallstar Combi 11

Technical Specifications 12

Burner Settings 13

Boiler Installation

Regulations 14

Boiler Sizing 14

Refurbishing An Old System 14

System Protection 14

Boiler Location 15

Wall Construction 15

Flue Terminating Positions 16

Fuel Supply System 17

Oil Supply 17

Installation Procedure

Wallstar 18-23

System Wallstar 24-31

Wallstar Combi 32-40

Condensate Drain 41

Wiring Diagrams

Wallstar 42

System Wallstar 42

Wallstar Combi 43

Boiler Maintenance

Baffle Removal 44

Fault Diagnosis

Wallstar Combi 45

Wallstar Combi Components 46

Contacts

Tel No: 01953 455400

Fax No: 01953 454483

Email: info@hrmboilers.co.uk or technical@hrmboilers.co.uk

1

Standard Wallstar, System Wallstar &

Wallstar Combi Manual

Contents Page

DESCRIPTION PAGE

Householder Information

Warranty Registration Document End Of Manual

Warranty 3

Extended Warranty 3

After Sales Service 3

Boiler Controls: Wallstar 4

System Wallstar 5

Wallstar Combi 6-7

Burner Lockout 8

Technical Specifications

Boiler Dimensions: Wallstar 9

Boiler Dimensions: System Wallstar 10

Boiler Dimensions: Wallstar Combi 11

Technical Specifications 12

Burner Settings 13

Boiler Installation

Regulations 14

Boiler Sizing 14

Refurbishing An Old System 14

System Protection 14

Boiler Location 15

Wall Construction 15

Flue Terminating Positions 16

Fuel Supply System 17

Oil Supply 17

Installation Procedure

Wallstar 18-23

System Wallstar 24-31

Wallstar Combi 32-40

Condensate Drain 41

Wiring Diagrams

Wallstar 42

System Wallstar 42

Wallstar Combi 43

Boiler Maintenance

Baffle Removal 44

Fault Diagnosis

Wallstar Combi 45

Wallstar Combi Components 46

Contacts

Tel No: 01953 455400

Fax No: 01953 454483

Email: info@hrmboilers.co.uk or technical@hrmboilers.co.uk

1

Standard Wallstar, System Wallstar &

Wallstar Combi Manual

Installation Procedure Continued – Wallstar Combi

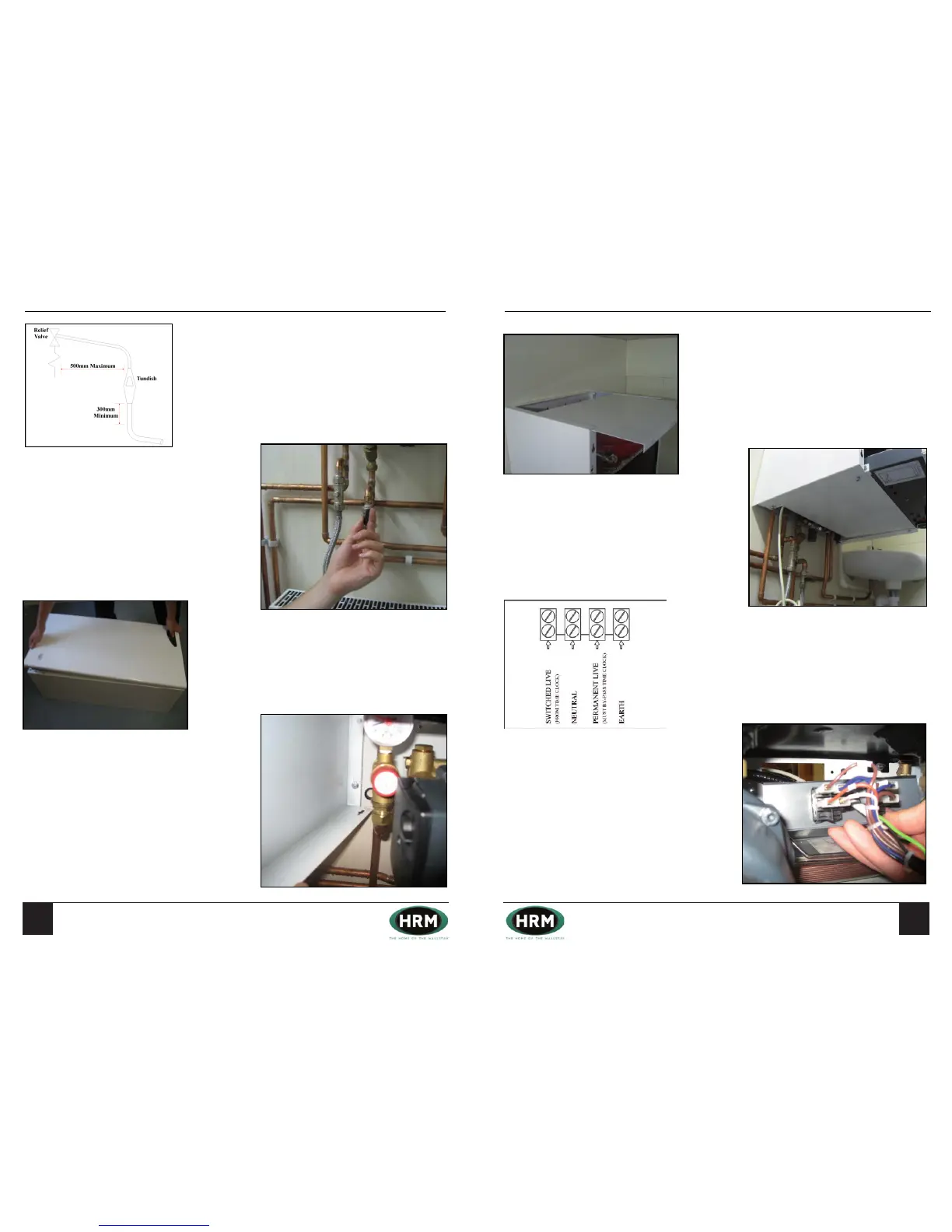

8. Tundish Installation

The flow from the pressure relief valve should be plumbed away.

A Tundish must be installed in accordance with Building

Regulations: G3.

9. Filling The System

Ensure the automatic air vent on top of the heat exchanger

is functioning correctly.

Open the filling loop valve and pressurise the system until 1

bar is showing on the pressure gauge. It may be necessary

after venting air from the heating system, to repeat this

operation in order to fill the system correctly.

10. Fit The White Casing

The casing is supplied pre-assembled. Remove the front cover

first, then the top panel and then the bottom panel which has the

control panel assembly attached to it.

11. Side Panels

Locate the side panels by hooking the slots over the screws

located in the wall plate. Tighten to secure.

34

Standard Wallstar, System Wallstar &

Wallstar Combi Manual

Installation Procedure Continued – Wallstar Combi

12. Top Panel

Slide the white case top panel under the returns on the two side

panels until it rests on the supports at the back. Secure the top to

the sides with the screws provided.

13. Bottom Panel & Control Panel

Slide the bottom panel, with the control panel assembly still

attached inside the white case. Align the screws on the

bottom panel up with the slots on the base of the side

panels and drop them through, slide the bottom panel back

and tighten the screws. Leave the control panel in the

forward position.

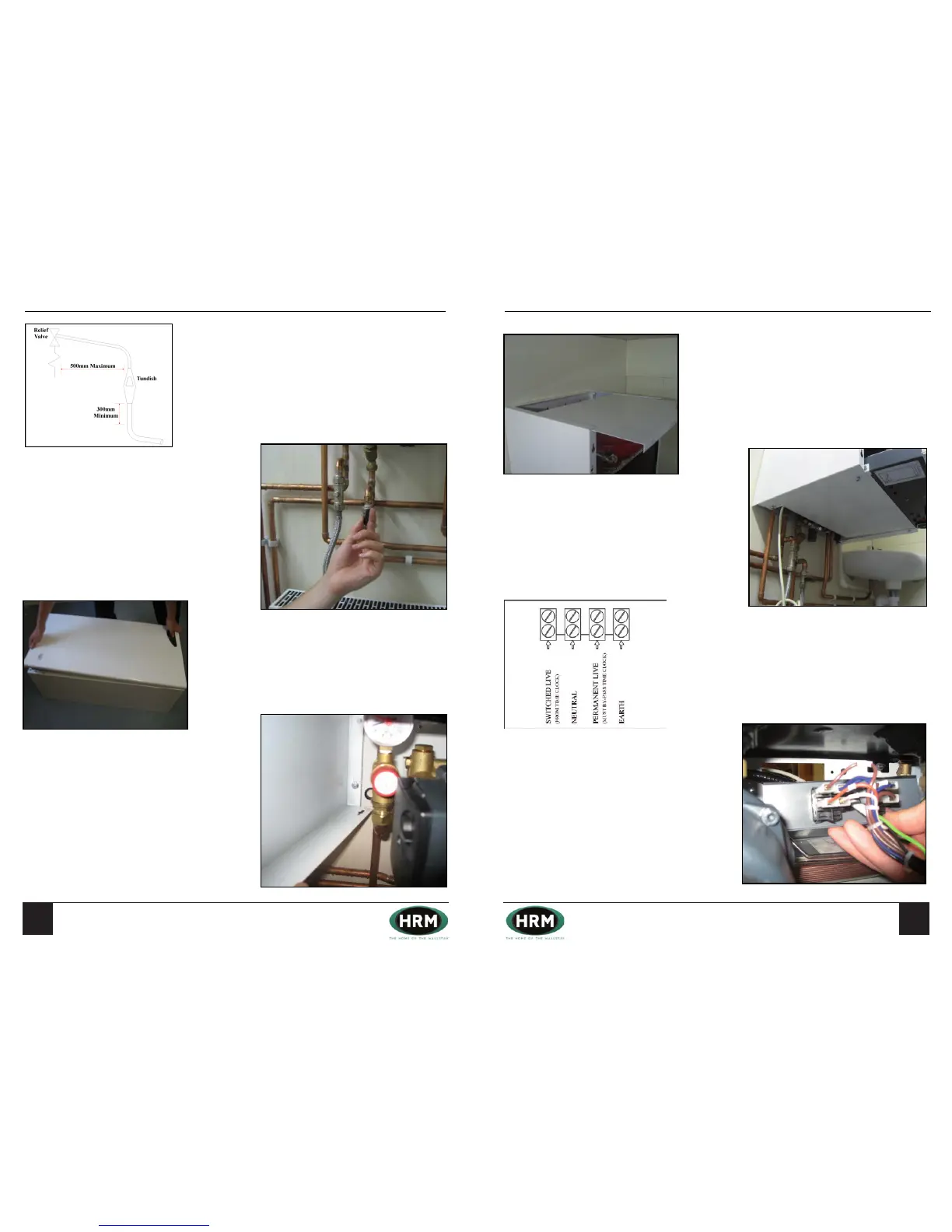

14. Mains Supply

A switched 13amp socket should be installed near the boiler.

The boiler is supplied with a 13amp plug (fused at 5amps) with a

1.5 metre lead.

For concealed cable entry, 20mm holes are provided in the wall

plate, alternatively use plastic ducting to any corner of the wall

plate.

15. Burner Lead

Pass the burner lead which is attached to the control panel

through the rectangular opening in the wall plate and secure

the switch panel. Ensure the switch plate gasket is in

position.

35

Standard Wallstar, System Wallstar &

Wallstar Combi Manual

A switched 13amp socket should be installed near the boiler.

The boiler is supplied with a plug (fused at 5amps) with a

1.5 metre lead.

Loading...

Loading...