Householder Information

IMPORTANT!

Your boiler must be commissioned in order to:

- Validate your warranty

- Ensure the boiler has been installed correctly and avoid premature failure

- Set the boiler to its optimum efficiency. Operating conditions for the boiler will vary from site to site, your

commissioning engineer has specialised equipment to check the oil pressure and analyse the exhaust gases for

temperature, smoke and carbon dioxide content.

Your installer will organise the commissioning of your boiler. Should you experience any difficulty locating an

engineer, our service department may be able to provide you with details of an engineer in your area.

“Benchmark” Installation, Commissioning and Service Record Log Book

Please ensure that your installer has completed all sections of the log book (found at the back of this manual).

The log book will be required in the event of any warranty work. Ensure that the service record is completed.

Warranty

Your HRM boiler is under warranty for 2 years from the date of installation.

Warranty Conditions

- The boiler must be installed and commissioned in accordance with our handbook

- The boiler must not be repaired, modified or tampered with by any person not authorised by HRM

Extended Warranty

The “Benchmark” and warranty registration document at the end of this manual should be completed as

appropriate by your installer / engineer. This is your record that the boiler has been correctly installed in accordance

with our recommendations. Return the warranty registration document to HRM in order to qualify for a further 3 year

warranty of the heat exchanger – a total of 5 years.

Extended Warranty Conditions

- The boiler must be serviced annually and maintained in accordance with this handbook. The

“Benchmark” service log is located at the back of this manual

- This warranty is in addition to your statutory and other legal rights

After Sales Service

- If your boiler fails during the warranty period contact your installer, who will be able to identify the

cause of the problem. If appropriate, your installer will contact us.

- Under no circumstances should “in warranty” work be undertaken without authorisation from the HRM

service department

- If you are unable to contact your installer please contact our service department. Quoting your boiler’s

serial number when phoning – this can be found on the cover of this manual.

Standard X-ternal & System X-ternal

Handbook

Householder Information

IMPORTANT!

Your boiler must be commissioned in order to:

- Validate your warranty

- Ensure the boiler has been installed correctly and avoid premature failure

- Set the boiler to its optimum efficiency. Operating conditions for the boiler will vary from site to site, your

commissioning engineer has specialised equipment to check the oil pressure and analyse the exhaust gases for

temperature, smoke and carbon dioxide content.

Your installer will organise the commissioning of your boiler. Should you experience any difficulty locating an

engineer, our service department may be able to provide you with details of an engineer in your area.

“Benchmark” Installation, Commissioning and Service Record Log Book

Please ensure that your installer has completed all sections of the log book (found at the back of this manual).

The log book will be required in the event of any warranty work. Ensure that the service record is completed.

Warranty

Your HRM boiler is under warranty for 2 years from the date of installation.

Warranty Conditions

- The boiler must be installed and commissioned in accordance with our handbook

- The boiler must not be repaired, modified or tampered with by any person not authorised by HRM

Extended Warranty

The “Benchmark” and warranty registration document at the end of this manual should be completed as

appropriate by your installer / engineer. This is your record that the boiler has been correctly installed in accordance

with our recommendations. Return the warranty registration document to HRM in order to qualify for a further 3 year

warranty of the heat exchanger – a total of 5 years.

Extended Warranty Conditions

- The boiler must be serviced annually and maintained in accordance with this handbook. The

“Benchmark” service log is located at the back of this manual

- This warranty is in addition to your statutory and other legal rights

After Sales Service

- If your boiler fails during the warranty period contact your installer, who will be able to identify the

cause of the problem. If appropriate, your installer will contact us.

- Under no circumstances should “in warranty” work be undertaken without authorisation from the HRM

service department

- If you are unable to contact your installer please contact our service department. Quoting your boiler’s

serial number when phoning – this can be found on the cover of this manual.

Standard X-ternal & System X-ternal

Handbook

Contents Page

DESCRIPTION PAGE

Householder Information

Warranty Registration Document End Of Manual

Warranty 3

Extended Warranty 3

After Sales Service 3

Boiler Controls: Wallstar 4

System Wallstar 5

Wallstar Combi 6-7

Burner Lockout 8

Technical Specifications

Boiler Dimensions: Wallstar 9

Boiler Dimensions: System Wallstar 10

Boiler Dimensions: Wallstar Combi 11

Technical Specifications 12

Burner Settings 13

Boiler Installation

Regulations 14

Boiler Sizing 14

Refurbishing An Old System 14

System Protection 14

Boiler Location 15

Wall Construction 15

Flue Terminating Positions 16

Fuel Supply System 17

Oil Supply 17

Installation Procedure

Wallstar 18-23

System Wallstar 24-31

Wallstar Combi 32-40

Condensate Drain 41

Wiring Diagrams

Wallstar 42

System Wallstar 42

Wallstar Combi 43

Boiler Maintenance

Baffle Removal 44

Fault Diagnosis

Wallstar Combi 45

Wallstar Combi Components 46

Contacts

Tel No: 01953 455400

Fax No: 01953 454483

Email: info@hrmboilers.co.uk or technical@hrmboilers.co.uk

1

Standard Wallstar, System Wallstar &

Wallstar Combi Manual

Contents Page

DESCRIPTION PAGE

Householder Information

Warranty Registration Document End Of Manual

Warranty 3

Extended Warranty 3

After Sales Service 3

Boiler Controls: Wallstar 4

System Wallstar 5

Wallstar Combi 6-7

Burner Lockout 8

Technical Specifications

Boiler Dimensions: Wallstar 9

Boiler Dimensions: System Wallstar 10

Boiler Dimensions: Wallstar Combi 11

Technical Specifications 12

Burner Settings 13

Boiler Installation

Regulations 14

Boiler Sizing 14

Refurbishing An Old System 14

System Protection 14

Boiler Location 15

Wall Construction 15

Flue Terminating Positions 16

Fuel Supply System 17

Oil Supply 17

Installation Procedure

Wallstar 18-23

System Wallstar 24-31

Wallstar Combi 32-40

Condensate Drain 41

Wiring Diagrams

Wallstar 42

System Wallstar 42

Wallstar Combi 43

Boiler Maintenance

Baffle Removal 44

Fault Diagnosis

Wallstar Combi 45

Wallstar Combi Components 46

Contacts

Tel No: 01953 455400

Fax No: 01953 454483

Email: info@hrmboilers.co.uk or technical@hrmboilers.co.uk

1

Standard Wallstar, System Wallstar &

Wallstar Combi Manual

Installation Procedure Continued - System Wallstar

23. Wall Duct Outer (Cont.)

Join the wall duct outer and wall duct inner together using the 4

supplied self drilling screws.

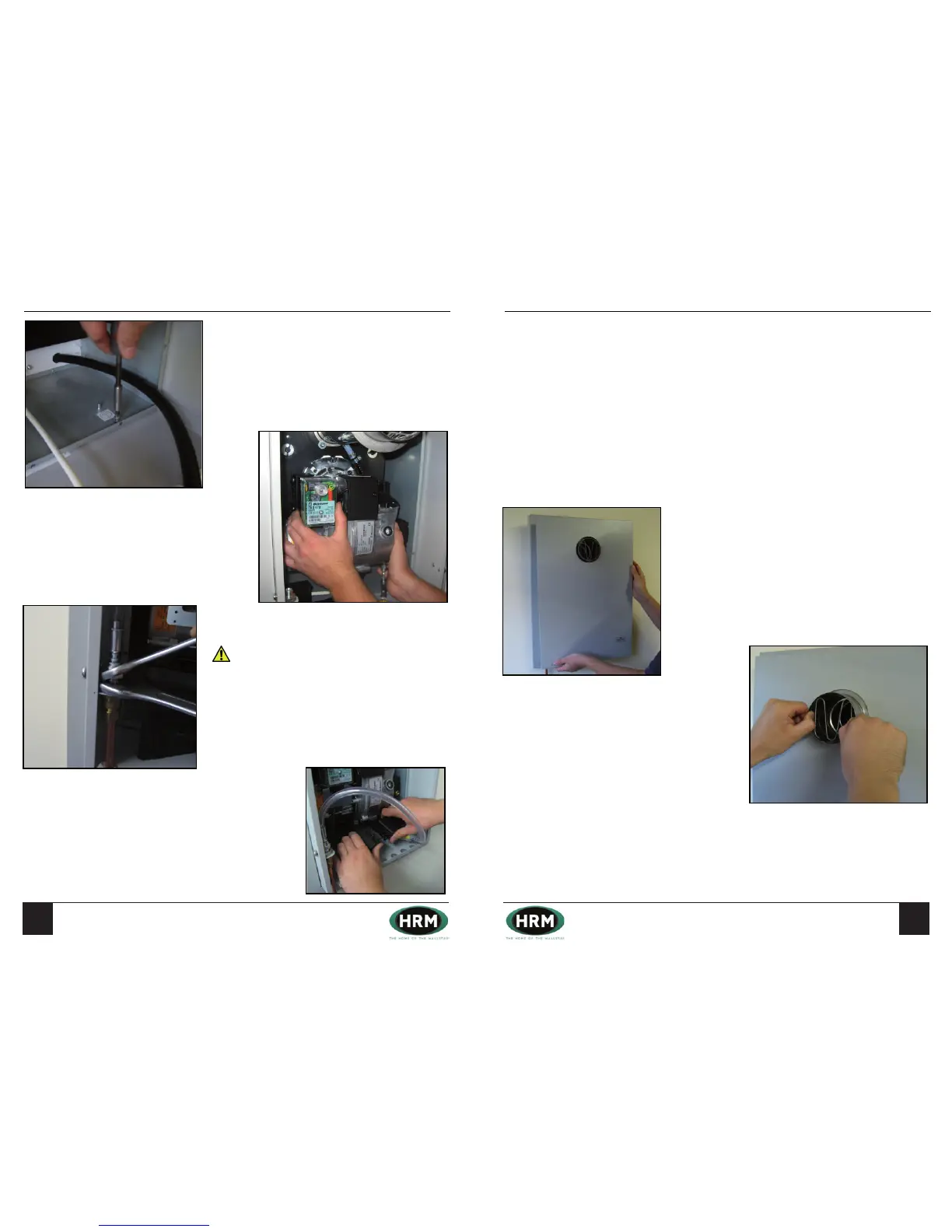

24. Burner

Fit the burner to the mounting flange on the silencer box.

25. Connect The Fuel Line

Connect the fuel line from the burner to the oil supply.

IMPORTANT: The Wallstar comes supplied with a remote

acting fire valve and has a non-return valve attached to the

burner pump. No additional non return valve must be used.

Should the boiler be used in conjunction with a purpose designed

underground tank, the foot valve found inside such tanks must be

removed or at least rendered ineffective. In addition to the sealed

fuel filter found in the boilers flexible fuel line, a replaceable

element fuel filter must be fitted near the tank.

Note: Please refer to page 17 of this manual for oil tank

installation recommendations.

26. Burner Lead

Connect the 5 pin plug and socket.

30

Standard Wallstar, System Wallstar &

Wallstar Combi Manual

Installation Procedure Continued - System Wallstar

27. Priming The Burner

Ensure both power and fuel supplies to the boiler are switched

on. Press the reset button, the burner will start it’s firing

sequence. To release air from the oil line slacken the vent plug

during this sequence. If ignition fails the burner will go to lock

out, wait 60 seconds and repeat the procedure.

28. Test The Fuel Supply

With the burner running, check the fuel supply for air leaks. It is

normal for a static air bubble to remain at the highest point of the oil

line, but a continuous stream of bubbles through the oil line

indicates that air is being drawn in. This must be cured before

proceeding.

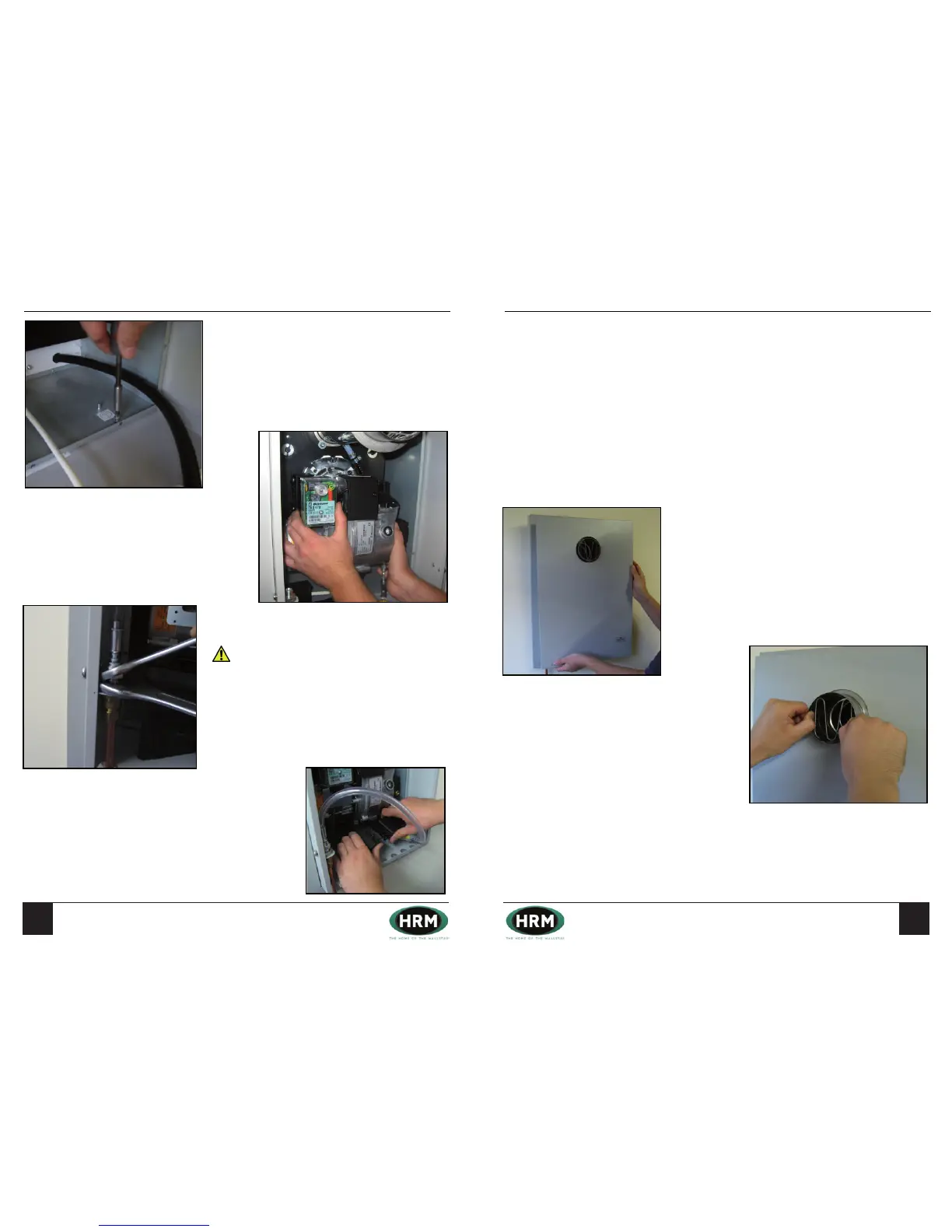

29. Access Door

Fit the access door onto the wall duct, secure it in place by

tightening the 2 screws located on both sides.

30. Flue Positioning

Pull the end of the flue out until the flange on it sits flush

against the back of the access door.

31. Commissioning the Boiler

Installation is complete. The boiler must now be commissioned

by a competent engineer. The “Benchmark” log found at the

back of this manual should be completed and the warranty

documentation returned to HRM Boilers Ltd.

31

Standard Wallstar, System Wallstar &

Wallstar Combi Manual

The Wallstar comes supplied with a non-

return valve attached to the burner pump. No additional non

return valve must be used. Should the boiler be used in

conjunction with a purpose designed underground tank, the

foot valve found inside such tanks must be removed or at least

rendered ineffective. In addition to the sealed fuel lter found in

the boilers exible fuel line, a replaceable element fuel lter must

be tted near the tank.

Ensure both power and fuel supplies to the boiler are switched

on. Press the reset button, the burner will start it’s ring

sequence. To release air from the oil line remove the vent plug

during this sequence.

Loading...

Loading...