Householder Information

IMPORTANT!

Your boiler must be commissioned in order to:

- Validate your warranty

- Ensure the boiler has been installed correctly and avoid premature failure

- Set the boiler to its optimum efficiency. Operating conditions for the boiler will vary from site to site, your

commissioning engineer has specialised equipment to check the oil pressure and analyse the exhaust gases for

temperature, smoke and carbon dioxide content.

Your installer will organise the commissioning of your boiler. Should you experience any difficulty locating an

engineer, our service department may be able to provide you with details of an engineer in your area.

“Benchmark” Installation, Commissioning and Service Record Log Book

Please ensure that your installer has completed all sections of the log book (found at the back of this manual).

The log book will be required in the event of any warranty work. Ensure that the service record is completed.

Warranty

Your HRM boiler is under warranty for 2 years from the date of installation.

Warranty Conditions

- The boiler must be installed and commissioned in accordance with our handbook

- The boiler must not be repaired, modified or tampered with by any person not authorised by HRM

Extended Warranty

The “Benchmark” and warranty registration document at the end of this manual should be completed as

appropriate by your installer / engineer. This is your record that the boiler has been correctly installed in accordance

with our recommendations. Return the warranty registration document to HRM in order to qualify for a further 3 year

warranty of the heat exchanger – a total of 5 years.

Extended Warranty Conditions

- The boiler must be serviced annually and maintained in accordance with this handbook. The

“Benchmark” service log is located at the back of this manual

- This warranty is in addition to your statutory and other legal rights

After Sales Service

- If your boiler fails during the warranty period contact your installer, who will be able to identify the

cause of the problem. If appropriate, your installer will contact us.

- Under no circumstances should “in warranty” work be undertaken without authorisation from the HRM

service department

- If you are unable to contact your installer please contact our service department. Quoting your boiler’s

serial number when phoning – this can be found on the cover of this manual.

Standard X-ternal & System X-ternal

Handbook

Householder Information

IMPORTANT!

Your boiler must be commissioned in order to:

- Validate your warranty

- Ensure the boiler has been installed correctly and avoid premature failure

- Set the boiler to its optimum efficiency. Operating conditions for the boiler will vary from site to site, your

commissioning engineer has specialised equipment to check the oil pressure and analyse the exhaust gases for

temperature, smoke and carbon dioxide content.

Your installer will organise the commissioning of your boiler. Should you experience any difficulty locating an

engineer, our service department may be able to provide you with details of an engineer in your area.

“Benchmark” Installation, Commissioning and Service Record Log Book

Please ensure that your installer has completed all sections of the log book (found at the back of this manual).

The log book will be required in the event of any warranty work. Ensure that the service record is completed.

Warranty

Your HRM boiler is under warranty for 2 years from the date of installation.

Warranty Conditions

- The boiler must be installed and commissioned in accordance with our handbook

- The boiler must not be repaired, modified or tampered with by any person not authorised by HRM

Extended Warranty

The “Benchmark” and warranty registration document at the end of this manual should be completed as

appropriate by your installer / engineer. This is your record that the boiler has been correctly installed in accordance

with our recommendations. Return the warranty registration document to HRM in order to qualify for a further 3 year

warranty of the heat exchanger – a total of 5 years.

Extended Warranty Conditions

- The boiler must be serviced annually and maintained in accordance with this handbook. The

“Benchmark” service log is located at the back of this manual

- This warranty is in addition to your statutory and other legal rights

After Sales Service

- If your boiler fails during the warranty period contact your installer, who will be able to identify the

cause of the problem. If appropriate, your installer will contact us.

- Under no circumstances should “in warranty” work be undertaken without authorisation from the HRM

service department

- If you are unable to contact your installer please contact our service department. Quoting your boiler’s

serial number when phoning – this can be found on the cover of this manual.

Standard X-ternal & System X-ternal

Handbook

Contents Page

DESCRIPTION PAGE

Householder Information

Warranty Registration Document End Of Manual

Warranty 3

Extended Warranty 3

After Sales Service 3

Boiler Controls: Wallstar 4

System Wallstar 5

Wallstar Combi 6-7

Burner Lockout 8

Technical Specifications

Boiler Dimensions: Wallstar 9

Boiler Dimensions: System Wallstar 10

Boiler Dimensions: Wallstar Combi 11

Technical Specifications 12

Burner Settings 13

Boiler Installation

Regulations 14

Boiler Sizing 14

Refurbishing An Old System 14

System Protection 14

Boiler Location 15

Wall Construction 15

Flue Terminating Positions 16

Fuel Supply System 17

Oil Supply 17

Installation Procedure

Wallstar 18-23

System Wallstar 24-31

Wallstar Combi 32-40

Condensate Drain 41

Wiring Diagrams

Wallstar 42

System Wallstar 42

Wallstar Combi 43

Boiler Maintenance

Baffle Removal 44

Fault Diagnosis

Wallstar Combi 45

Wallstar Combi Components 46

Contacts

Tel No: 01953 455400

Fax No: 01953 454483

Email: info@hrmboilers.co.uk or technical@hrmboilers.co.uk

1

Standard Wallstar, System Wallstar &

Wallstar Combi Manual

Contents Page

DESCRIPTION PAGE

Householder Information

Warranty Registration Document End Of Manual

Warranty 3

Extended Warranty 3

After Sales Service 3

Boiler Controls: Wallstar 4

System Wallstar 5

Wallstar Combi 6-7

Burner Lockout 8

Technical Specifications

Boiler Dimensions: Wallstar 9

Boiler Dimensions: System Wallstar 10

Boiler Dimensions: Wallstar Combi 11

Technical Specifications 12

Burner Settings 13

Boiler Installation

Regulations 14

Boiler Sizing 14

Refurbishing An Old System 14

System Protection 14

Boiler Location 15

Wall Construction 15

Flue Terminating Positions 16

Fuel Supply System 17

Oil Supply 17

Installation Procedure

Wallstar 18-23

System Wallstar 24-31

Wallstar Combi 32-40

Condensate Drain 41

Wiring Diagrams

Wallstar 42

System Wallstar 42

Wallstar Combi 43

Boiler Maintenance

Baffle Removal 44

Fault Diagnosis

Wallstar Combi 45

Wallstar Combi Components 46

Contacts

Tel No: 01953 455400

Fax No: 01953 454483

Email: info@hrmboilers.co.uk or technical@hrmboilers.co.uk

1

Standard Wallstar, System Wallstar &

Wallstar Combi Manual

Boiler Maintenance

Servicing

The boiler should be serviced annually. Should you experience any difficulty in locating an engineer, our service

department may be able to provide you with the contact details of an engineer in your area.

IMPORTANT: Isolate the power supply before servicing the boiler.

Servicing Steps

1. Remove the burner and combustion chamber baffles/insulation, clean the internal heat exchanger surfaces and

components. Replace the combustion chamber baffles and insulation with new items.

2. Check and replace seals, gaskets and flexible oil lines as appropriate.

3. Clean or replace filter elements and de-sludge the oil tank.

4. Dismantle the burner assembly and clean. Fit a new nozzle. For instructions on how to carry this out please read

the separate burner instructions supplied with your boiler.

5. Check the oil pressure and flue gas analysis. Adjust the burner settings as appropriate.

IMPORTANT: Do not use a wire brush to clean flue ways.

Baffle Replacement

(

Priming the Burner

Ensure both power and fuel supplies to the boiler are switched on. Press the reset button. The burner will start it’s

firing sequence. To release air from the oil line slacken the vent plug during this sequence. If ignition fails the burner

will go to lock out. Wait 60 seconds and repeat the procedure.

44

Standard Wallstar, System Wallstar &

Wallstar Combi Manual

Wallstar Combi Fault Diagnosis

No heating or domestic hot water (DHW)

- If the heating and DHW works when the test switch is in the “test” position, check the plug and socket

connection from the micro switch.

- Is the circulation pump working?

Cold DHW, heating functions satisfactorily

- Pipe work for the “mains in” and DHW have been connected the wrong way round.

Warm DHW, heating functions satisfactorily

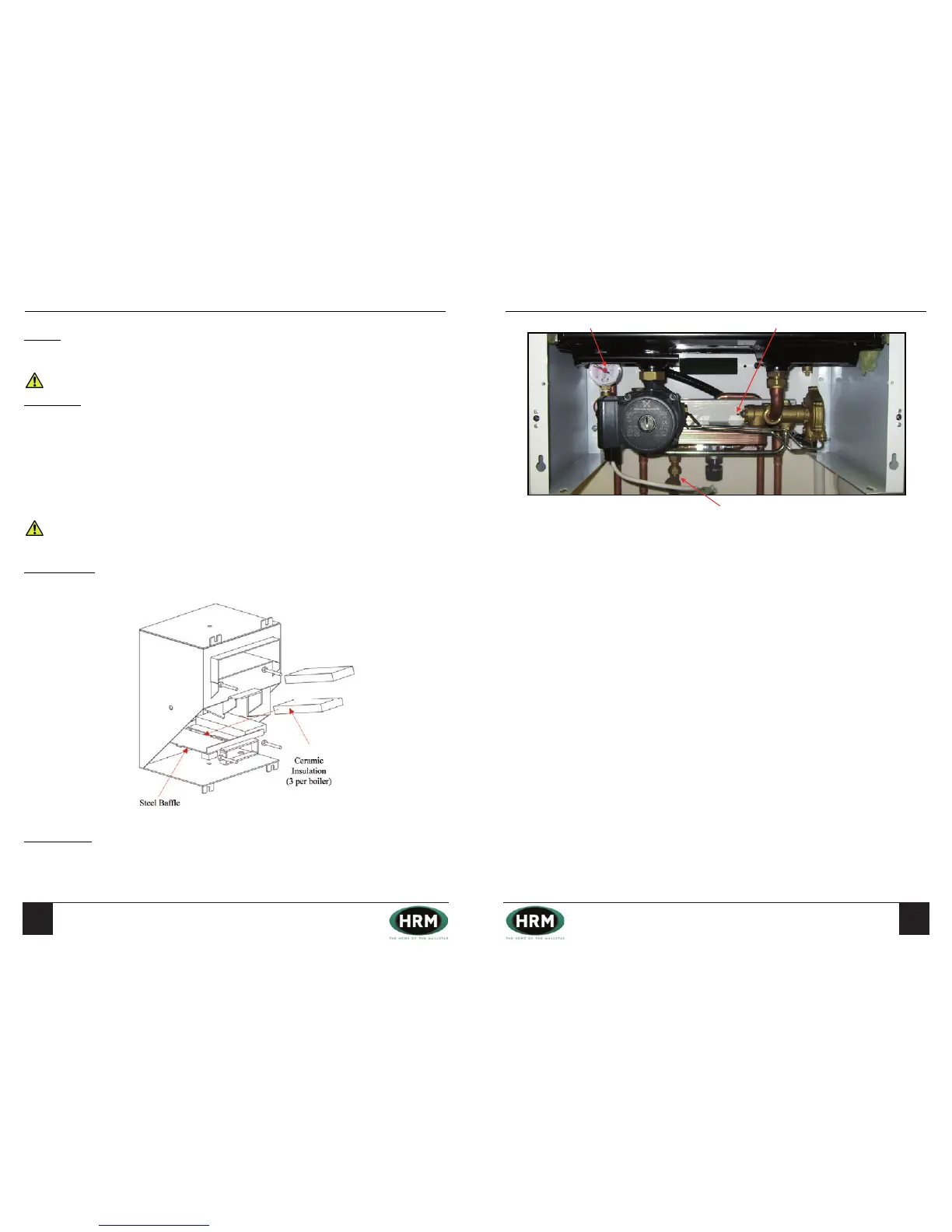

- Is the system pressure set to one bar (when cold)?

- Is the black plastic plug in the automatic air vent open?

- Is there a combustion problem/faulty nozzle?

- Is the mains water temperature low? The boiler will raise the mains water temperature by 35

°C at a

flow rate of 10.5 litres per minute.

- Check the operation of the mixing valve – is the “hot water” (right hand) inlet to the valve excessively

hot indicating that water is not flowing through the valve?

- If the “hot water” inlet to the mixing valve is cool, the plate heat exchanger may be

blocked/contaminated.

No heating, DHW functions satisfactorily

- Has the plunger on diverter valve stuck in the out position? Press the plunger a few times to free, or

dismantle the diverter valve assembly and clean.

DHW flow is less than 10.5 litres

- Is the mains water pressure sufficient? It should be greater than 1.5bar or 15 litres per minute.

- Is the mains water filter blocked?

Heating runs constantly

- Has the switch under the burner been left in the test position?

- Has the heating time clock been left in the permanently “on” position?

The boiler overheat thermostat needs resetting frequently

- Has the boiler lost system pressure?

System pressure is low

- Recharge system pressure by opening the filling loop valve and increasing pressure to the jet point

indicator on the pressure gauge (approximately 1 bar).

45

Standard Wallstar, System Wallstar &

Wallstar Combi Manual

Mains Filter

Pressure Gauge Diverter Valve Plunger

Ensure both power and fuel supplies to the boiler are switched on. Press the reset button. The burner will start it’s

ring sequence. To release air from the oil line remove the vent plug during this sequence.

Loading...

Loading...