4. Slide second clamp ring loosely over Hush Cushion

®

and up to previously tightened clamp ring. Do not tighten.

5. Unscrew legs until there is a space of approximately 1/4” between the top of the upper housing and the Hush Cushion

®

. Raise disposer until

the upper housing slides into the Hush Cushion

®

.

Slide the loose clamp ring between the two lower beads on the Hush Cushion

®

and tighten.

6. Assemble swirl spray or swirl sprays as shown in Figure 8. The method of assembly of the swirl sprays is typical. Other combinations of con-

vertible and fixed swirl sprays are available. The outlet hole of fixed spray head should be horizontal to promote swirling action in cone sink.

(convertible spray see Figure 9.)

7. Connect copper tube or tubes to swirl sprays and bend in gradual curve to connect to fittings in valves. See Figure 7.

8. Thread special nipple into drain outlet, slide hush connector over pipe and assemble and tighten clamp ring in two grooves.

NOTE: ALL PLUMBING AND ELECTRICAL CONNECTIONS SHOULD BE MADE ACCORDING TO LOCAL CODES.

INSTALLATION DIMENSIONS AND DRAINLINE CONNECTIONS

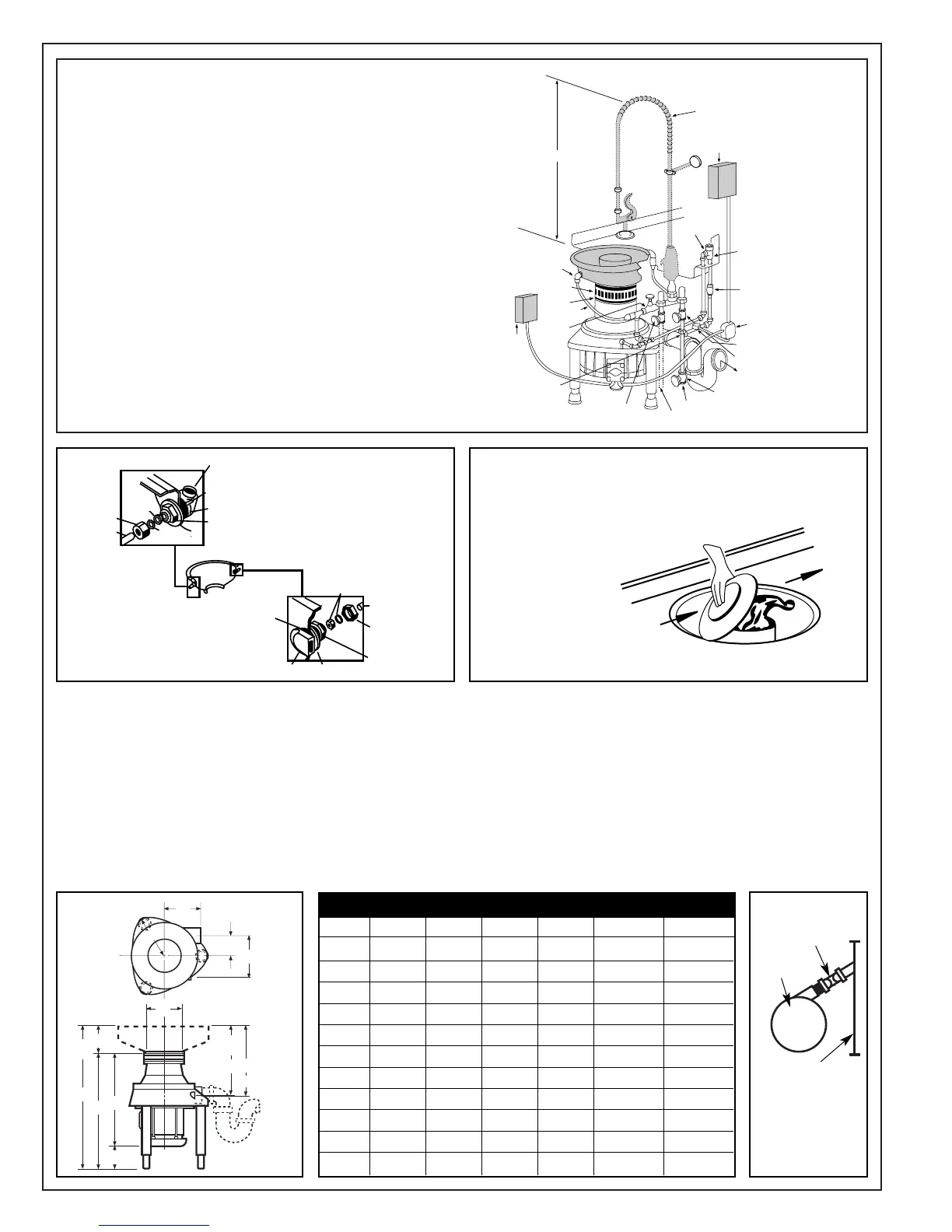

FIG. 7

NOTE:

A globe valve used for metering flow to prevent solenoid

hammering must be installed between solenoid valve and

disposer. See Fig. 7. Any valve ahead of the solenoid valve

must be opened and cause no restrictions.

IMPORTANT! Do not test or run disposer without mini-

mum water flow (see Plumbing Installation) as this will

damage the seal and void the warranty.

NOTE:

Disposer assembly includes disposer, outlet, nipple, Hush

Cushion

®

, clamps and supporting legs. Other items must be

purchased separately. Items shown in gray in Figure 7 are

available in equipment groups ordered separately.

1" MIN.

SEE FIG. 11

APPROX. 40"

FIG. 8 FIG. 9 CONVERTIBLE SPRAY

AERATOR SPRAY

SPRAY GASKETS

STEEL WASHER

CONICAL –

BRASS WASHERS

NUT

LOCK

NUT

CONICAL

WASHER

TUBING

LOCK

NUT

TUBING

NUT

STEEL WASHERSPRAY HEAD

BRASS

WASHERS

SPRAY HEAD

GASKET

The convertible spray

should be located

opposite the direction

of travel of dishes in

scrapping operation.

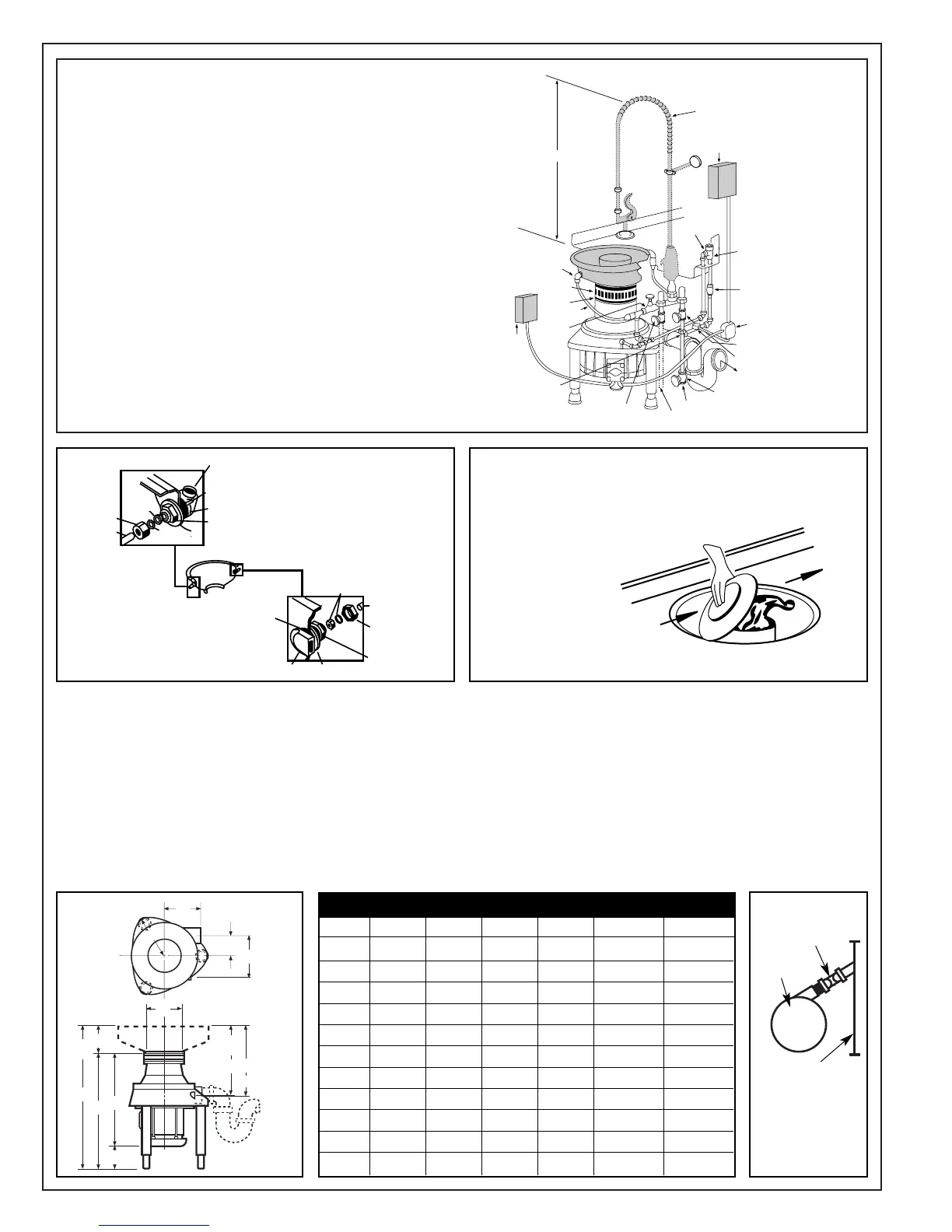

FIG. 10 FIG. 11

DIMENSIONS

2000-1 2000-3 3000-3 5000-3 5000-38 10000-3

A

32

3

/

8 - 35

1

/

8 32

3

/

8 - 35

1

/

8 32

3

/

8 - 35

1

/

8 32

7

/

8 - 35

3

/

8 32

61

/

64 - 35

29

/

64 32

61

/

64 - 35

29

/

64

B 21

5

/16 20

9

/16 22

15

/32 22

1

/2 22

37

/64 23

37

/64

C 6

5

/8 6

5

/8 6

5

/8 6

5

/8 6

5

/8 6

5

/8

D 6666 8 8

E 16

1

/4 16

1

/4 17

15

/16 17

19

/64 17

3

/8 17

3

/8

F 16 16 16

1

/8 16

5

/8 16

23

/32 16

23

/32

G

25

3

/4 - 28

1

/2 25

3

/4 - 28

1

/2 25

3

/4 - 28

1

/2 26

1

/4 - 28

3

/4 26

21

/64 - 28

53

/64 26

21

/64 - 28

53

/64

H 5

1

/8 5

1

/8 6

7

/8 8

7

/16 8

7

/16 8

7

/16

J 5

3

/4 5

3

/4 8

7

/8 88 8

K 2

5

/8 2

5

/8 3

3

/8 4

3

/4 4

3

/4 4

3

/4

L 6

7

/16 6

7

/16 7

13

/16 10

13

/16 10

13

/16 10

13

/16

*

*

TRAP

WALL

DISPOSER

If space between dis-

poser and wall is

insufficient to allow

for installation of trap,

waste line may have

to be at an angle to

the wall as shown.

J

K

H

E

F

A*

G*

B

C

G minus B

D

Water

Inlet

Drain

Slope =

1/4” Per

Foot

L

Sink

Flange

*

Legs are adjustable beyond the minimum shown in the screw adjustment. 2” clearance must be maintained beneath unit for proper ventillation.

Loading...

Loading...