TI 420 v5 0515 Page 5

1. Thermostatic water mixing valves are control devices

which must be cleaned and maintained on a regular

basis. Powers specifies periodic maintenance at least

once a year or immediately after any changes are made

to the plumbing system. Annual cleaning is recom-

mended, however, frequency of cleaning depends on

quality of local water conditions. Refer to the Preventive

Maintenance section for recommended cleaning proce-

dure.

2.

Warning: To prevent injury to the user, it is important

to periodically check the maximum temperature

adjustment on the valve for (1) any sign of motor wear

or (2) motor failure (refer to the Thermostatic Motor

Testing section). The above conditions in the thermo-

static motor can cause the valve to pass full hot water.

3. Note: The handle rotation setting must be adjusted to

limit the distance the user can rotate the handle

towards the full hot water position.

4. Quick closing valves may cause damage to the mixing

valve by creating shock waves. When the HydroGuard

supplies tempered water to self-closing and/or solenoid

valves, Powers recommends installing a shock

absorber (Powers Part #460-353) on the discharge line,

which will protect the HydroGuard thermostatic motor

from damage.

5. Position the 420 valve as close as possible to outlet fix-

ture to avoid waste of energy and water (except in

applications where the valve is used as a primary mix-

ing valve).

Adherence to these guidelines and recommenda-

tions promotes safe product use and ensures proper

valve performance.

To Disassemble:

1. Turn off hot & cold water supply-stops (required for this retrofit)

2. Remove the handle and trim plate

3. Remove 4 bonnet screws and bonnet assembly

4. Remove all internal components from valve body

5. At this point you should have an empty valve body.

IMPORTANT: After completing any maintenance/repairs,

reset the maximum discharge temperature by resetting the

handle rotation stop as necessary (refer to Maximum

Temperature Setting section).

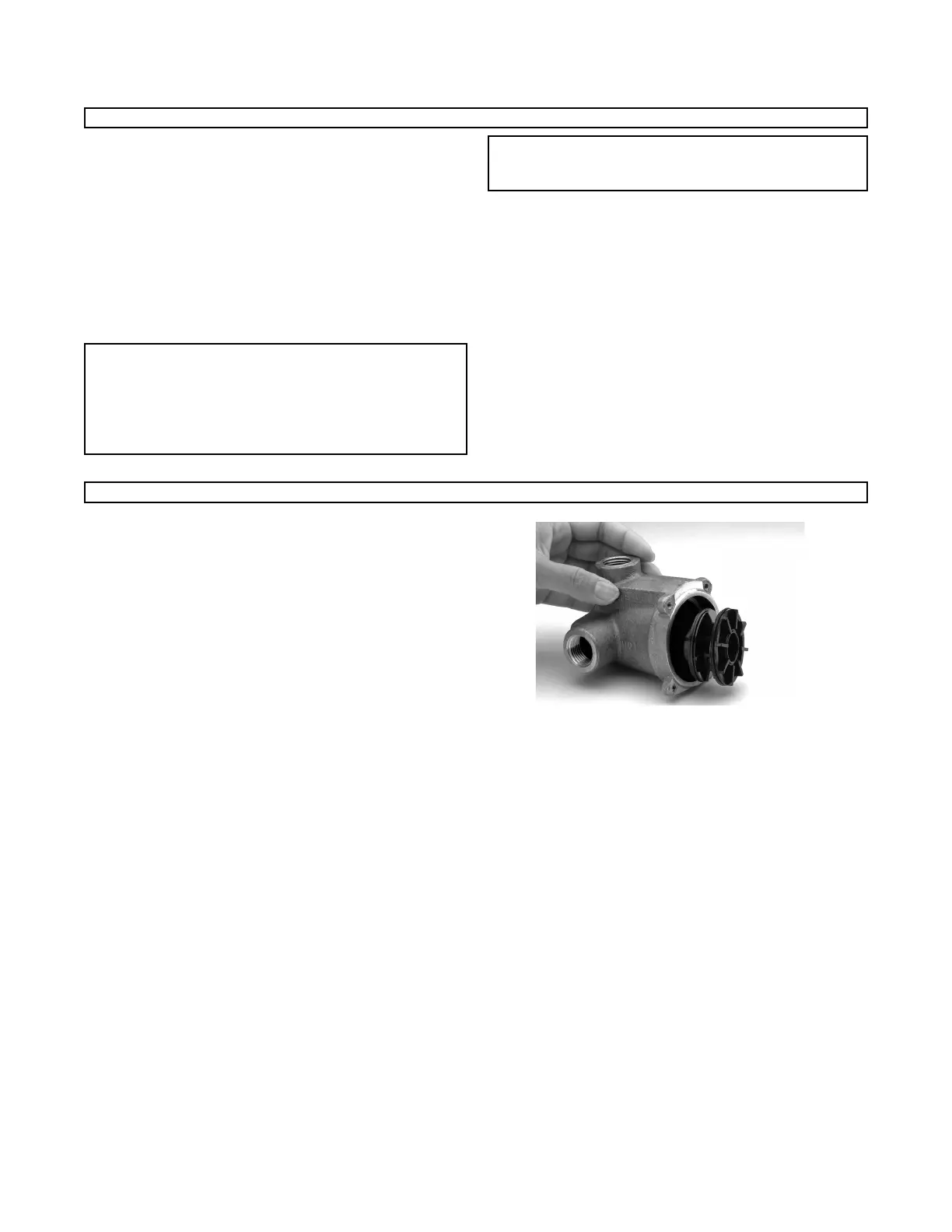

To Reassemble:

1. Ensure the inside of the valve body is free of deposits

and debris. Clean as necessary.

2. Push the cartridge into the body without the “O” rings

installed. The cartridge should slide in easily, and

bottom out with its large fins just inside the front

surface of the casting. If the cartridge is difficult to

install, or does not go in all the way, remove the

cartridge and clean the the body or remove any

obstructions. Repeat this step until the cartridge

installs easily.

3. Remove the cartridge and install the 2 “O” rings. One is

slightly larger than the other. The larger one goes closest

to the front (fins). Lubricate the “O” rings with silicon

lubricant.

4. Install the cartridge back into the body. The cartridge

should go in until the large fins are just inside the

front surface of the casting (same position as in step 2).

If you cannot push it in all the way due to O-rings, use

bonnet and two (2) screws to force in.

5. Place the wax element into the stem assembly, stem

side first, and place this bonnet-stem-motor assembly

into/onto the valve body. Rotate the bonnet assembly to

line up the bonnet screw holes and reinstall and tighten

the four bonnet screws.

6. With handle, rotate the stem assembly clock-wise, until it

bottoms out on the cartridge. At this point your valve is

in the off position.

7. Turn the hot and cold water supplies back on and verify

there is no leakage.

8. Your valve should now be set properly. Verify proper

operation by rotating the stem from the off position,

counter-clockwise, to the high temperature position.

Verify the temperature does not exceed your desired

maximum temperature. Rotate stem back to the off

position.

9. Replace trim plate and handle.

SAFETY GUIDELINES - ALL MODELS

SERVICING

Loading...

Loading...