Check the bolts and nuts for tightening torque

……every 250 h (initially at 50 h)

Check the tightness at initial 50h and then every 250 h. Tighten it to the set torque if needed. Replace it with bolts

and nuts with same or higher grade.

Important: please use the torque wrench to check the torques of bolts and nuts!

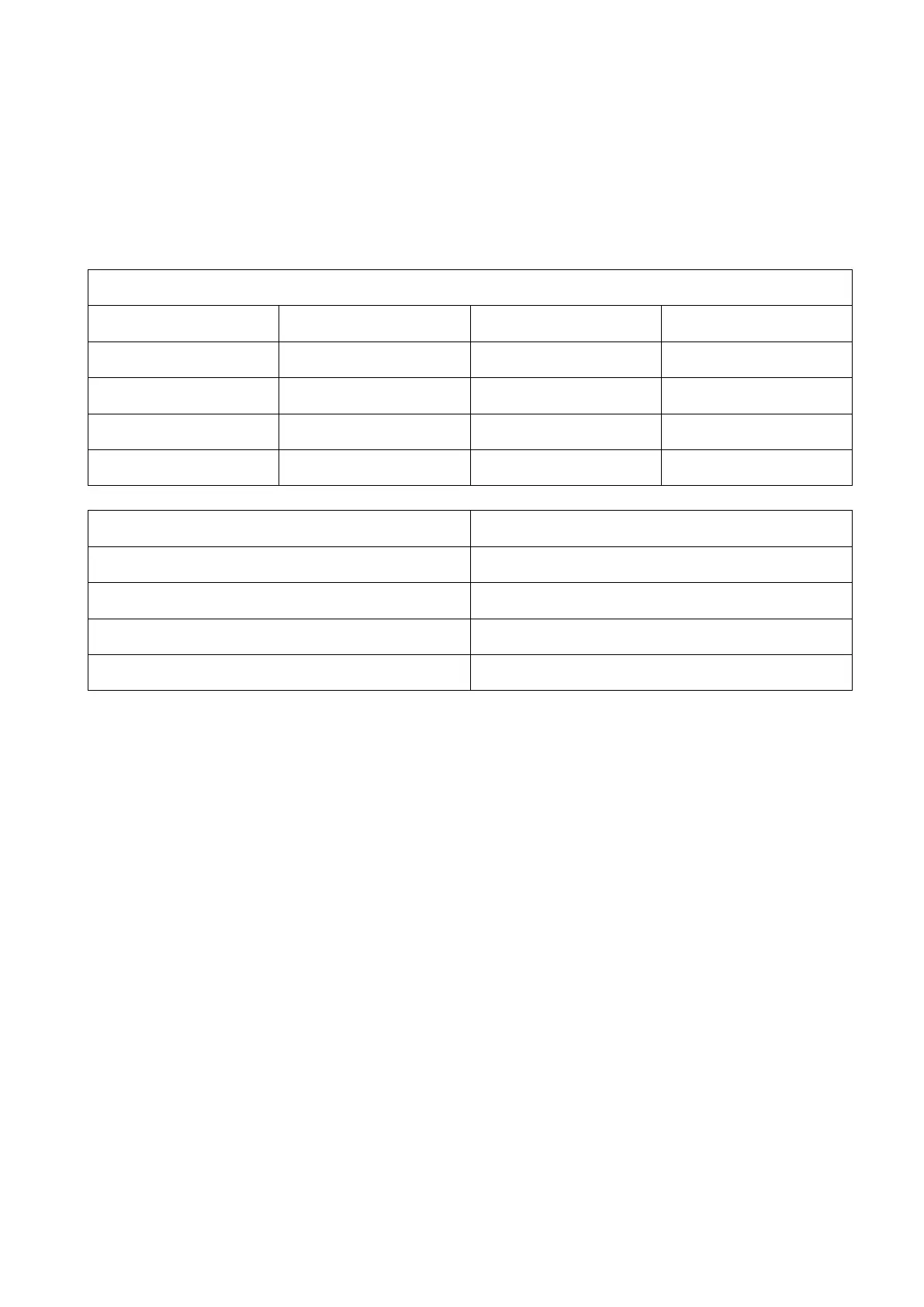

2. Torque of main components: (N.m)

M16 bolts fixing the traveling motor

M16 bolts fixing the sprocket

M20 bolts fixing the slewing bearing

M20 bolts fixing the swing mechanism

Important:

1.

Before installed, the bolts and nuts should be cleaned.

2.

Grease the bolts and the nuts (such as the white zinc b able to be dissolved to lubricant), so as to stabilize

their abrasion coefficient.

3.

The counterweight bolts should be kept tightened up.

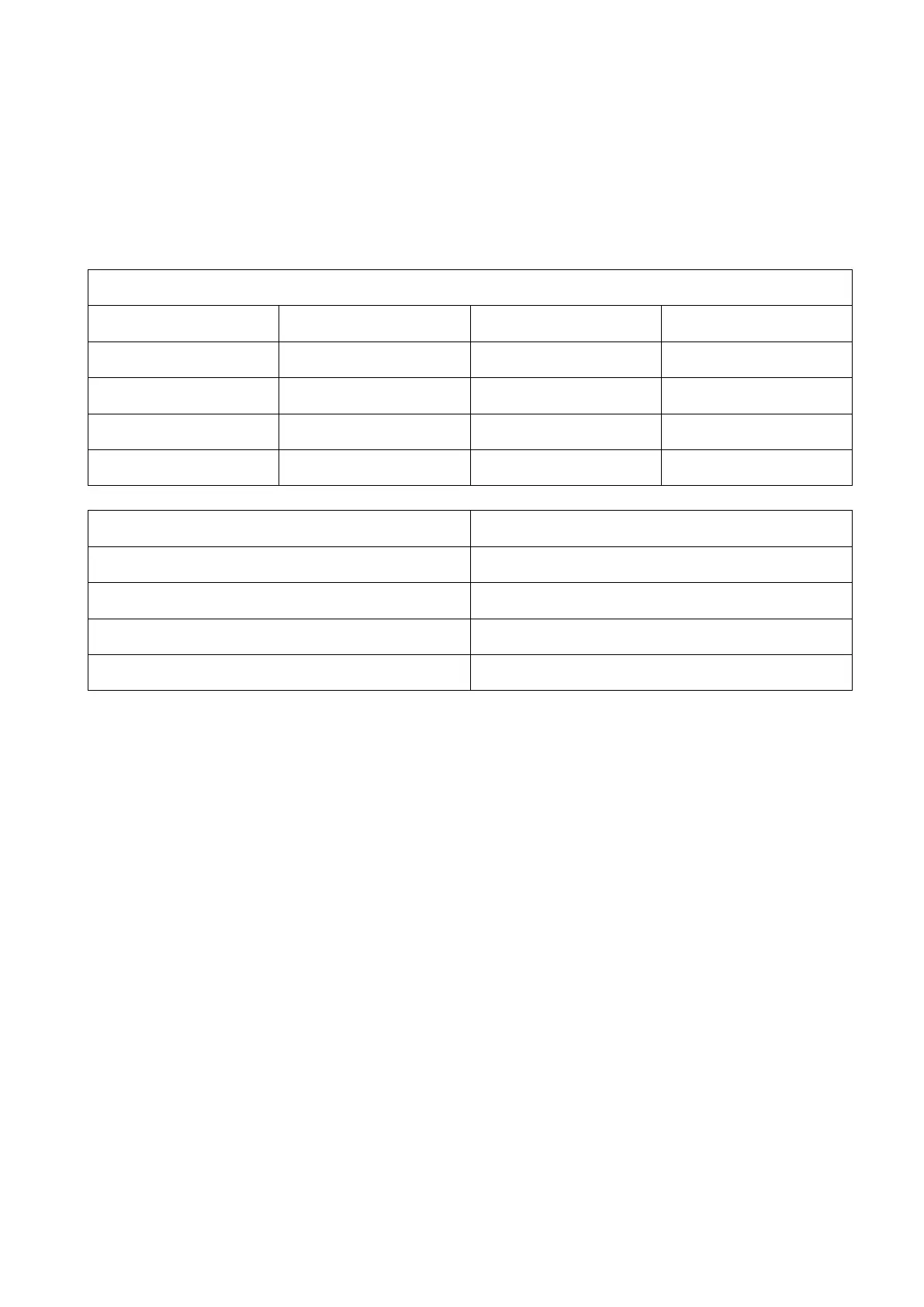

Caution: all the tightening torques should be expressed with kgf.m.

For example: use a wrench with 1m long to tighten the bolts and nuts, and apply 12kgf of force to the end of

wrench, generating the following torque:

1m×12kgf=12kgf.m

To generate the same torque with 0.25m wrench: 0.25m×y=12kgf.m

Needed force: y=12kgf.m/0.25m=48kgf

Loading...

Loading...